Slitting transposition variable speed conveying device and method

A technology of variable speed conveying and cutting rotation, applied in metal processing and other directions, can solve the problems of high cost, poor adaptability, complex structure, etc., and achieve the effect of strong adaptability, stable work and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

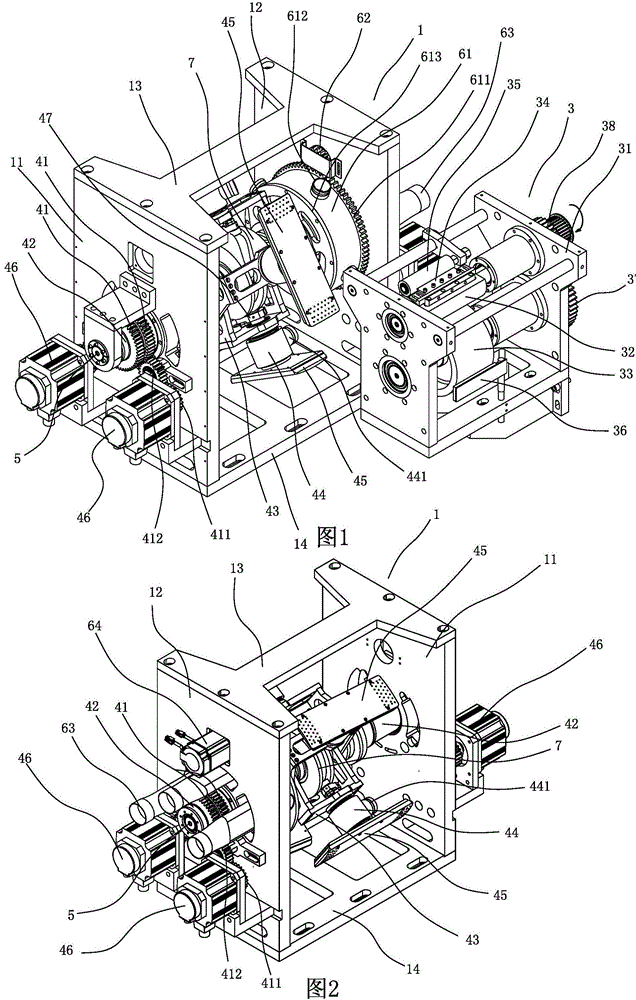

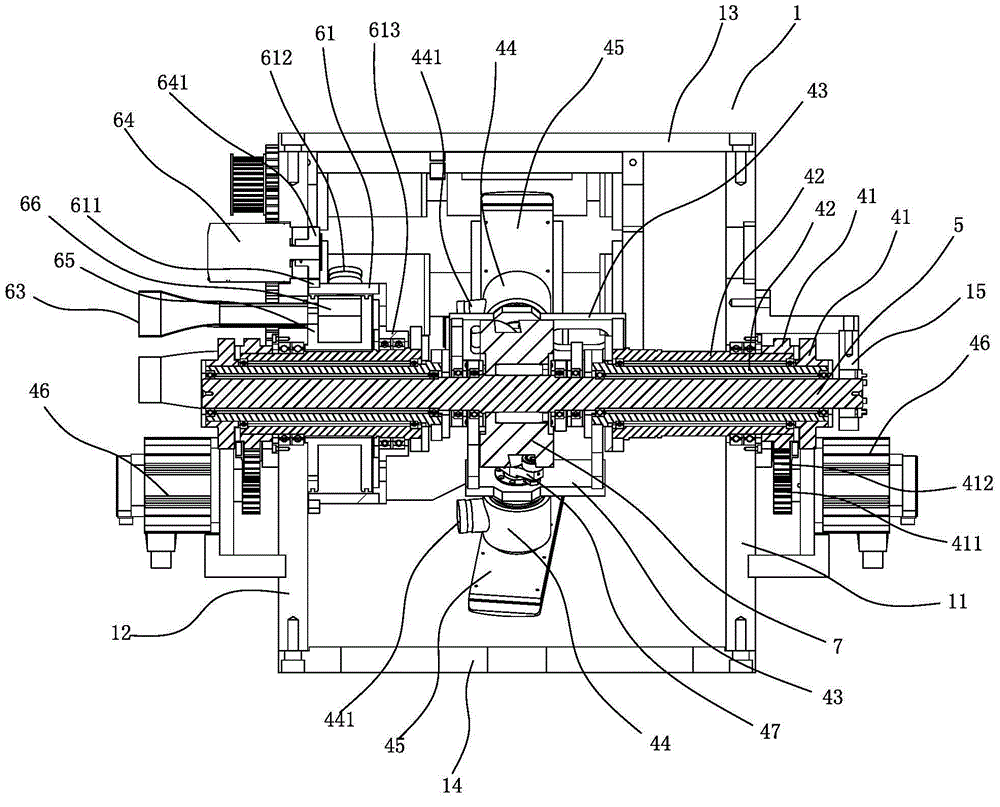

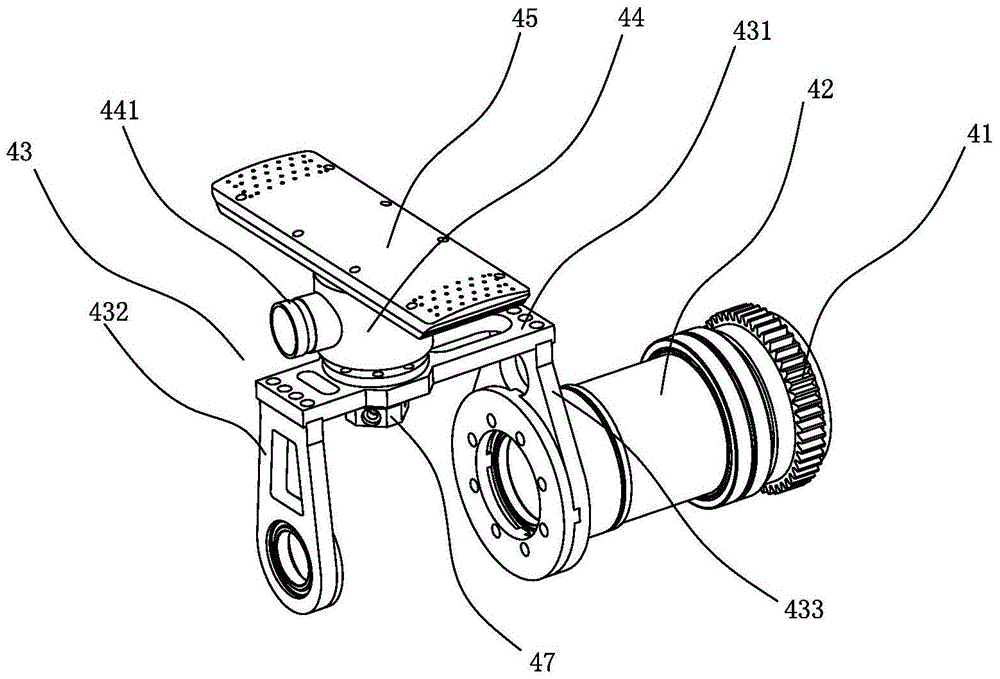

[0023] refer to Figure 1 to Figure 5 As shown, a slitting, indexing and variable speed conveying device includes a frame 1, a dotted line slitting mechanism 3, a support shaft 5, a rotary sleeve 42, a first servo motor 46, a rotary frame 43, a negative pressure adsorption block 45, and a cylindrical cam 7. Rotary negative pressure mechanism.

[0024] The frame 1 is assembled by the left and right side plates 11, 12 and the upper and lower connecting plates 13, 14, the support shaft 5 is fixedly arranged between the left and right side plates 11, 12 through the connecting piece 15, and the cylindrical cam 7 is fixedly arranged In the middle of the support shaft 5, the rotary sleeve 42 includes two sleeves on the left support shaft 5 of the cylindrical cam 7 and two on the right support shaft 5 of the cylindrical cam 7. The two rotary sleeves 42 on the same side are mutually connected by bearings. Rotatably sleeved on the support shaft 5, the rotary sleeve 42 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com