Livestock feeding device

A feeding device and livestock technology, which is applied in the field of feeding, can solve the problems of unfavorable feeding of poultry by large grains of food, inability to perform quantitative automatic conveying, and easy food clumps, etc., and achieve the effects of avoiding clogging, facilitating feeding, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

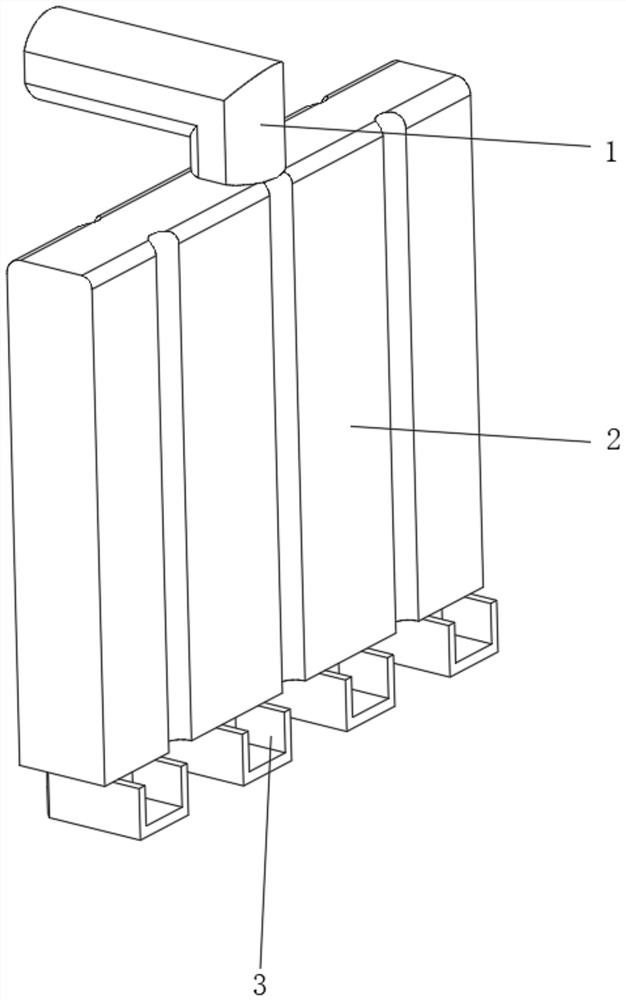

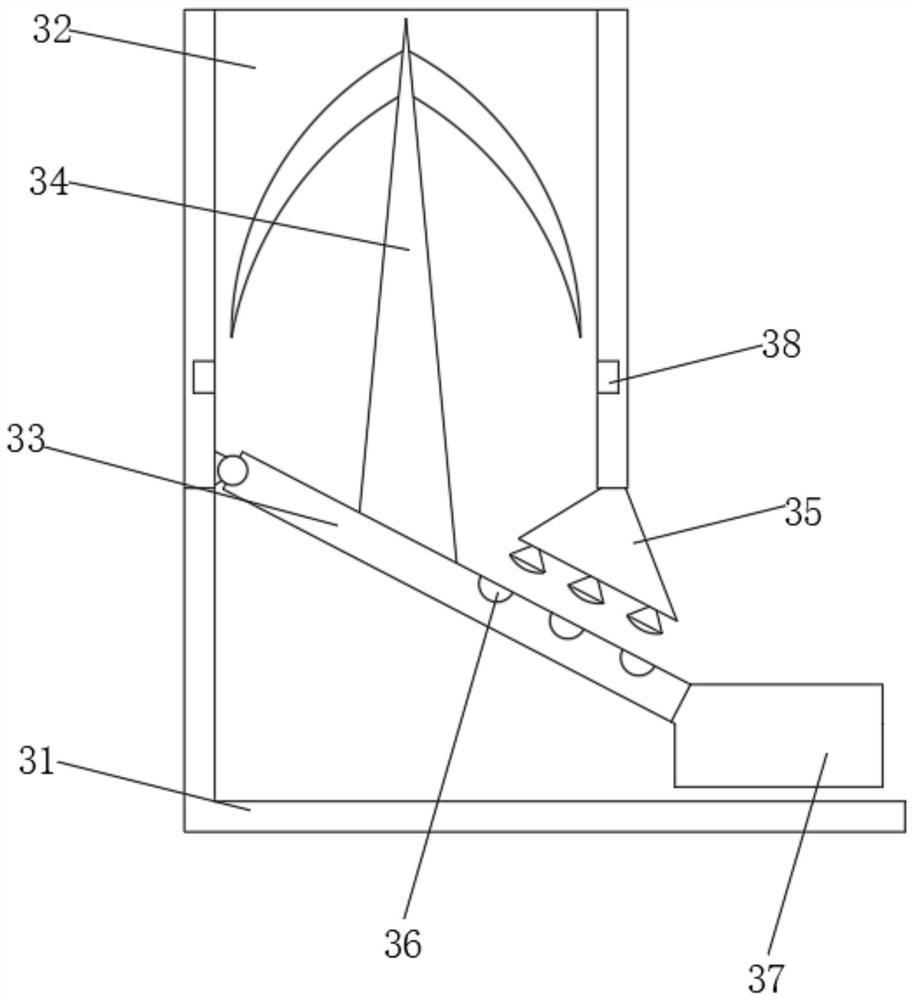

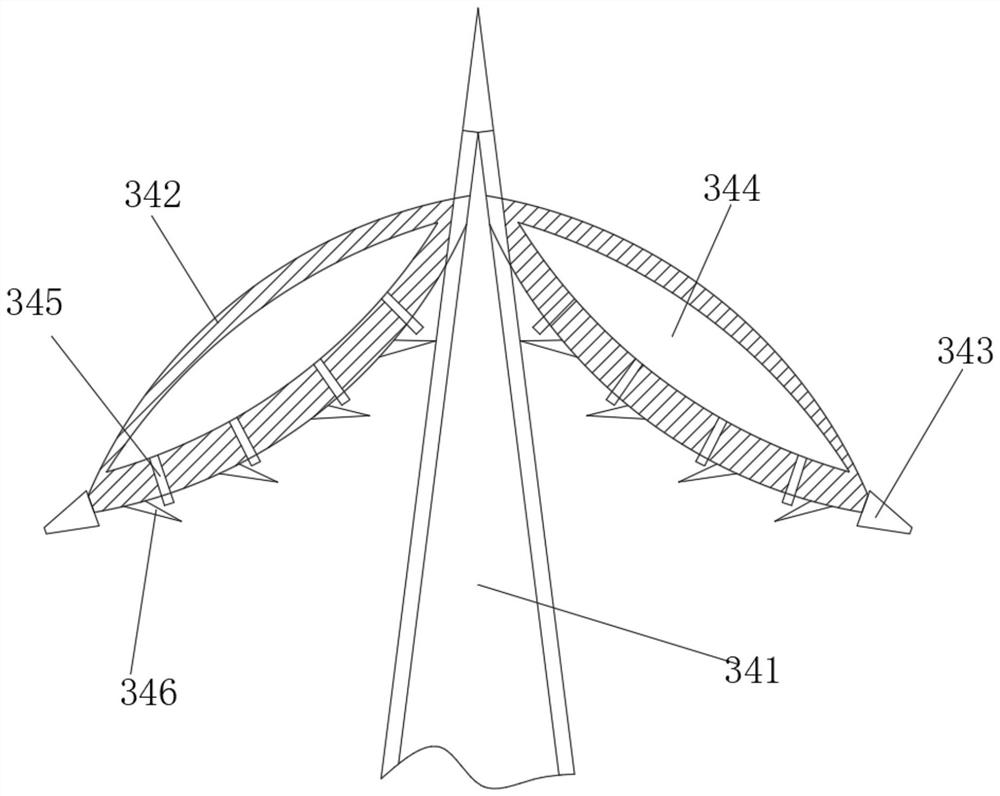

[0034] Such as Figure 1-3 As shown, the present invention provides a technical solution: a feeding device for livestock, including a transmission pipeline 1, the output end of the transmission pipeline 1 is evenly provided with a dispersing feeding trough 2, and the output end of the low end of the dispersing feeding trough 2 is fixed. Be connected with quantitative feeding mechanism 3, quantitative feeding mechanism 3 comprises support bottom frame 31, the top of support bottom frame 31 is fixedly connected with guide channel 32, and the top of guide material channel 32 is fixedly communicated with the output end of dispersive feeding tank 2, The left side of the support bottom frame 31 and the position close to the left side are rotatably connected with a guide slant plate 33, the top of the guide slant plate 33 is fixedly connected with a quantitative pulling component 34, and the right side of the bottom of the guide channel 32 is fixedly connected with a scraper Assembli...

Embodiment 2

[0039] Such as Figure 4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a livestock feeding device, the scraper assembly 35 includes a blocking cone 351, and the top of the blocking cone 351 is fixed to the guide channel 32 Connection, the surface of the bottom of the blocking cone plate 351 is evenly and symmetrically fixedly connected with an elastic sloping plate 352 .

[0040] The position near the outer side of the elastic swash plate 352 is fixedly connected with the supporting airbag 353 , and the outer surface of the supporting airbag 353 is uniformly and fixedly connected with the cutting assembly 354 . Ensure the cutting of large particles of food, and facilitate the feeding of poultry.

Embodiment 3

[0042] Such as Figure 5-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a feeding device for livestock, the cutting assembly 354 includes an elastic cutter a1, the top of the elastic cutter a1 and the elastic The swash plate 352 is fixedly connected, the left and right sides of the elastic cutter a1 are provided with a storage inner groove a2, and the interior of the storage inner groove a2 is fixedly connected with a driving protrusion a3. The edge of the elastic cutter a1 can shovel food, and its own elasticity can ensure that the equipment will not be damaged when shaking.

[0043] The shaker groove assembly 36 includes a guide outer plate 361 , the top of which is fixed to the guide slant plate 33 and kept horizontal, and the right side of the guide outer plate 361 is fixedly connected with a screening material arc plate 362 .

[0044] The top of the right side of the sieve arc plate 362 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com