Wiring substrate and semiconductor device using the same

A technology for wiring substrates and semiconductors, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, and semiconductor/solid-state device components, etc., and can solve the problem of decreased productivity of semiconductor devices, deformation of wiring 5 for electroplating, difficulty in electrical inspection of semiconductor component substrates 1, etc. problems, to achieve the effect of improving productivity and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, a wiring board showing an embodiment of the present invention and a semiconductor device using the wiring board will be described in detail with reference to the drawings.

[0037] A wiring board according to an embodiment of the present invention will be described.

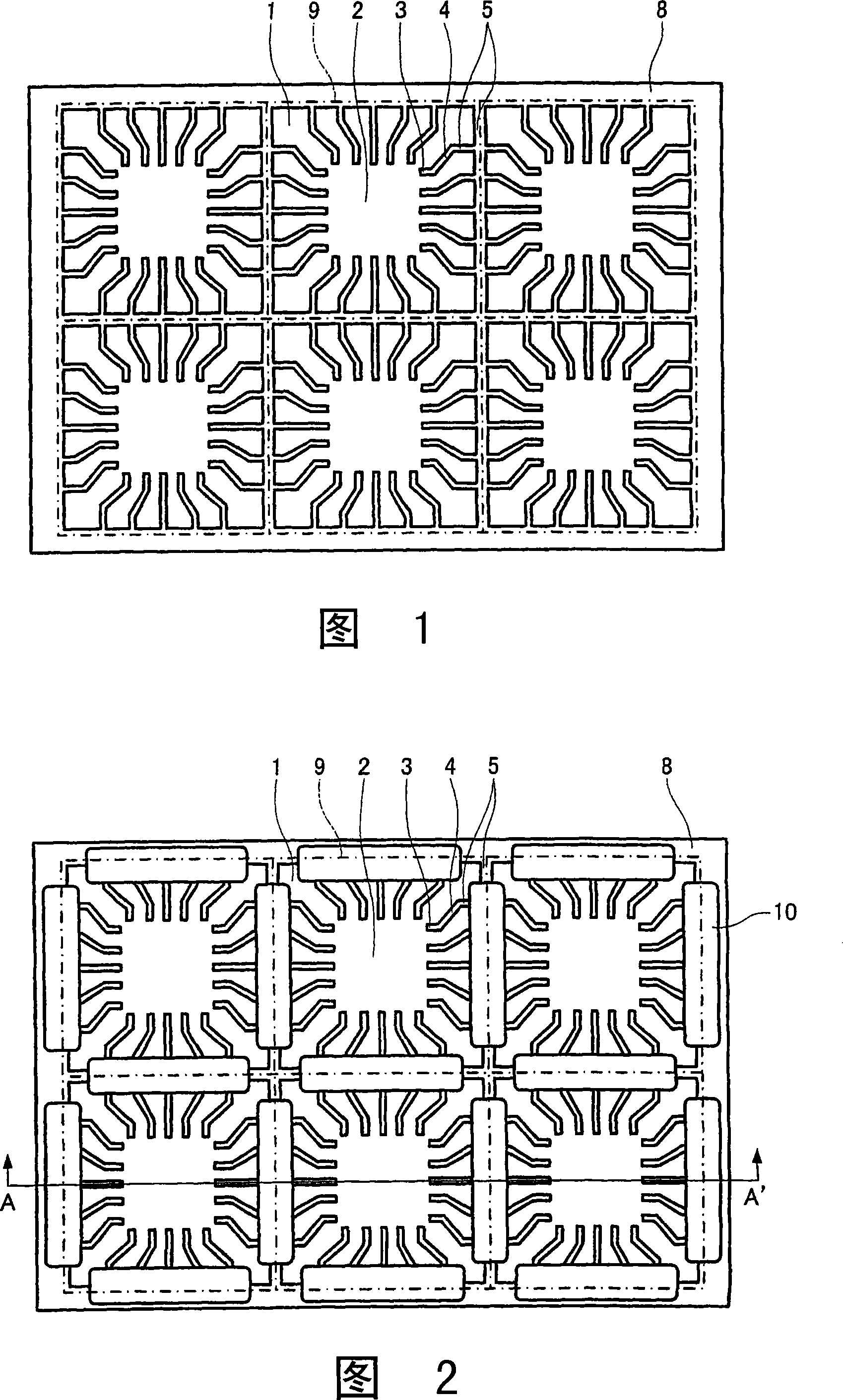

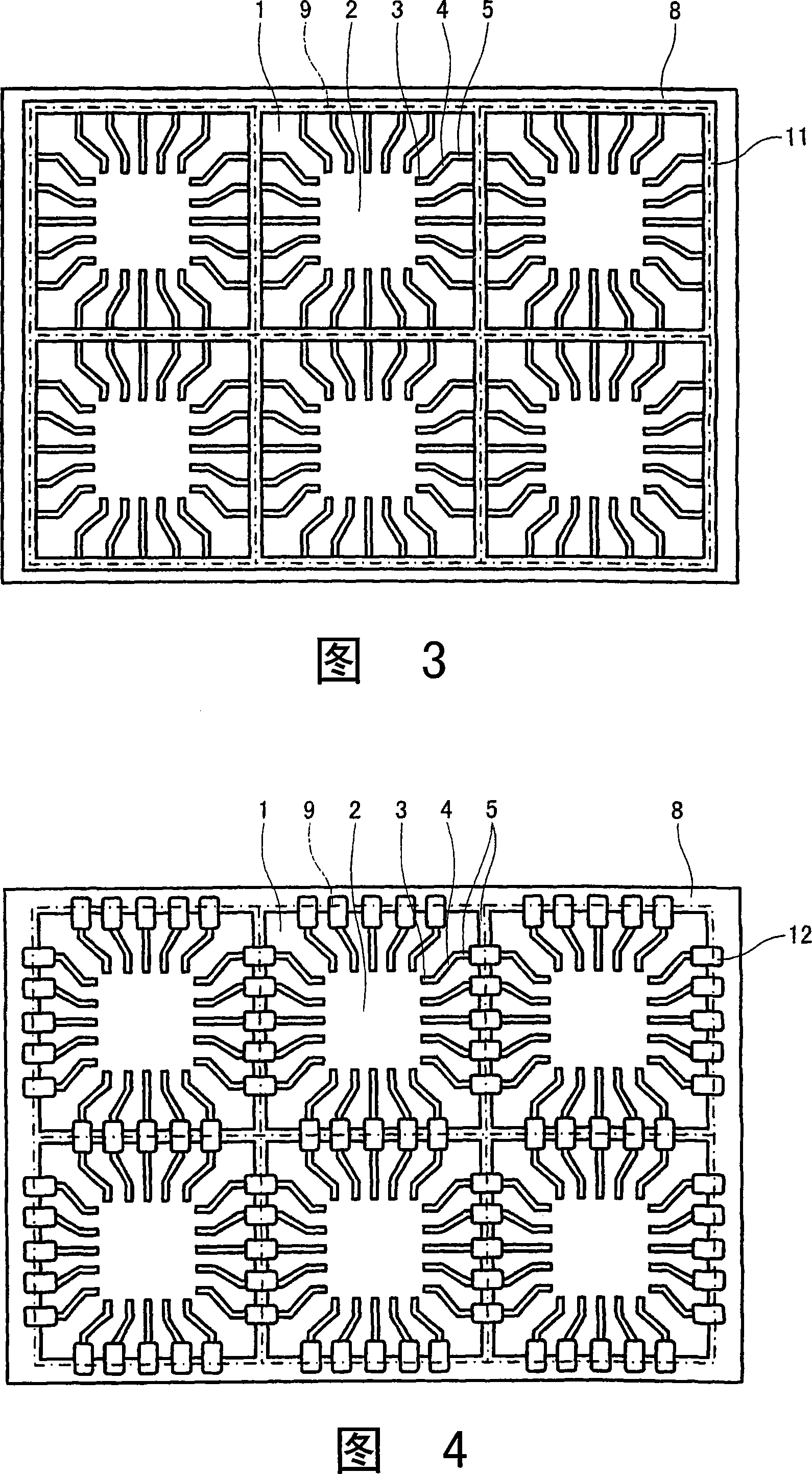

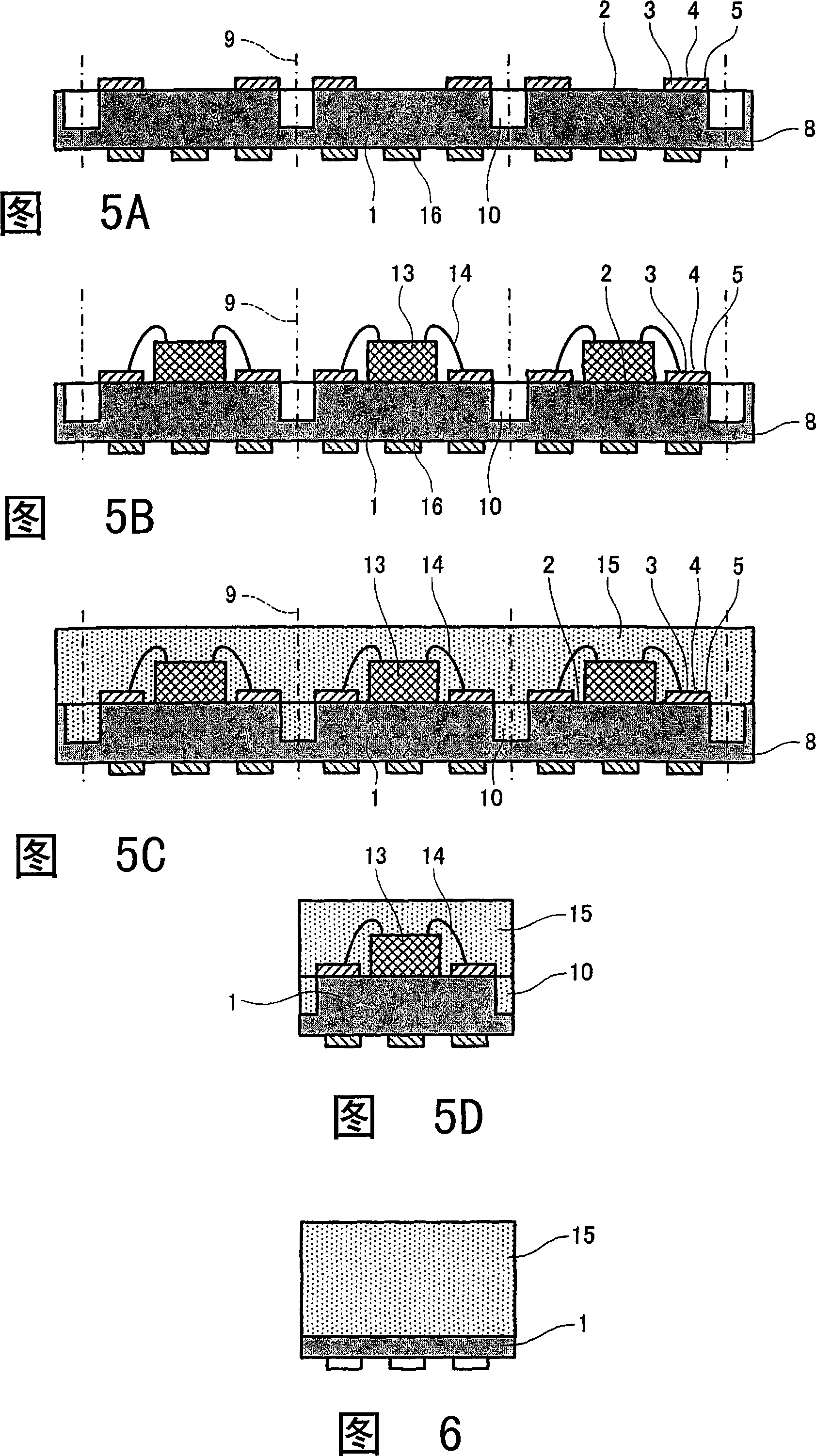

[0038] FIG. 1 is a plan view showing a state in which a wiring pattern is formed on a wiring substrate of this embodiment, and FIG. 2 is a diagram showing a groove-shaped concave portion formed only on the wiring portion for plating on the outer periphery of each semiconductor package substrate on the wiring substrate of this embodiment. FIG. 3 is a plan view showing a state in which an annular recess is formed over the entire outer periphery of each semiconductor module substrate on the wiring board of this embodiment. FIG. It is a plan view of a state where an independent recess is formed for each plating wiring on the outer periphery of each semiconductor module substrate.

[0039] First, in FIG....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com