Moving loading device for plate shape substrates and its storing device

A technology of storage device and loading device, which is applied in the direction of packaging, transportation and packaging, and stacking of objects, etc. It can solve the problems of deformation or damage of sheet substrates, achieve the effects of preventing deformation or damage, reducing insertion space, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, according to the drawings, the moving loading device and storage device for sheet substrates of the present invention will be introduced by taking glass substrates as moving and loading objects as an example.

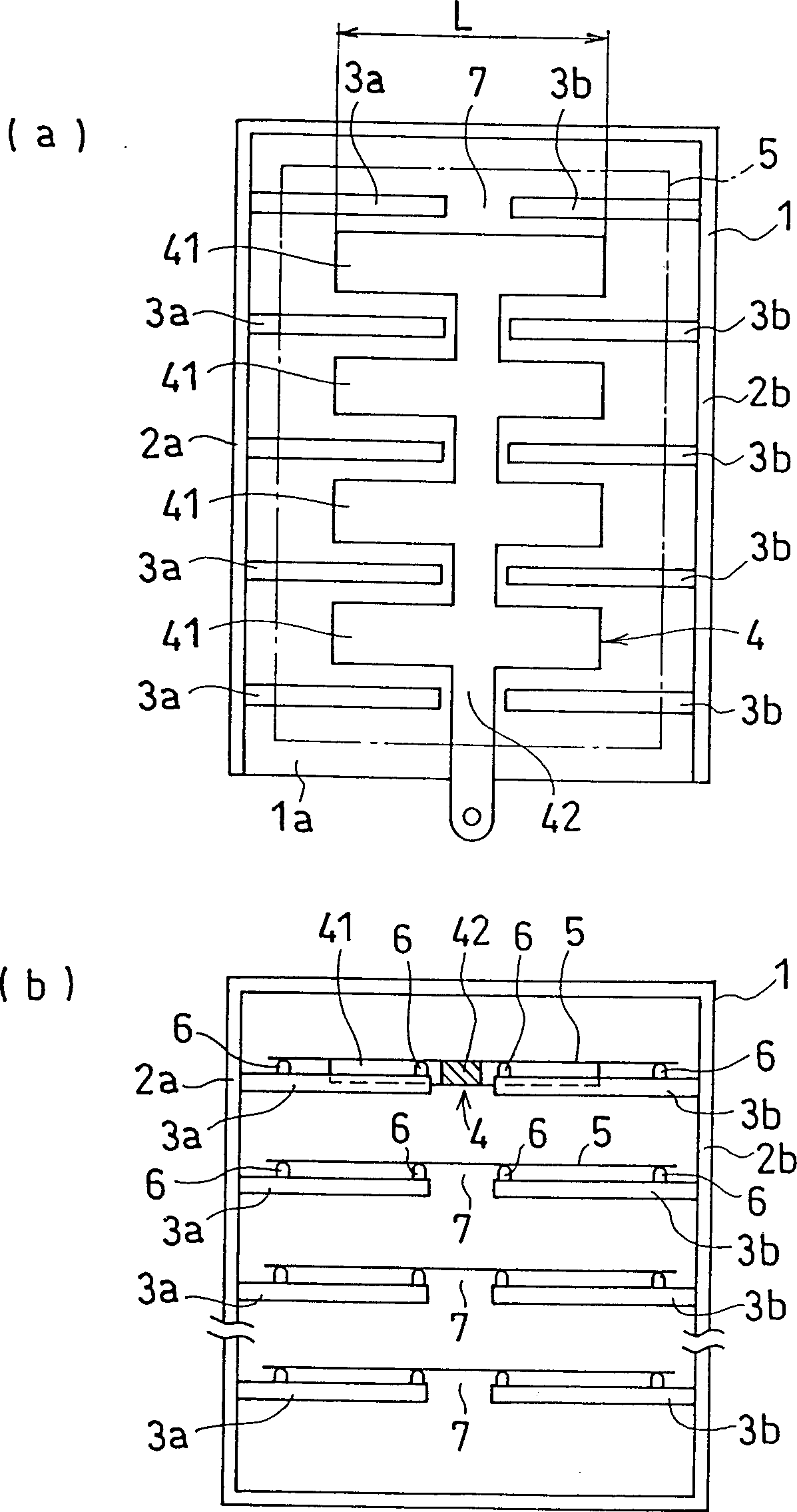

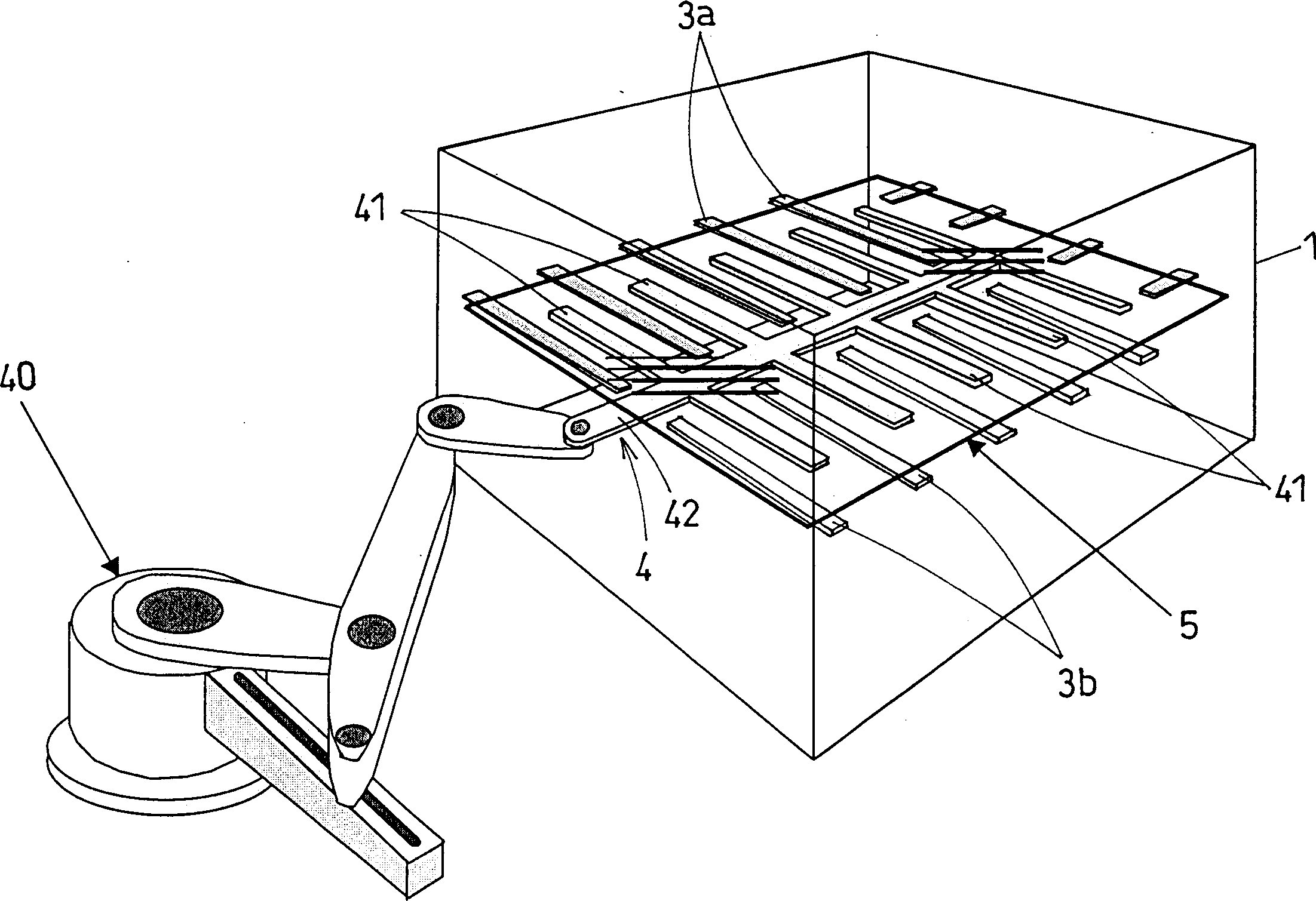

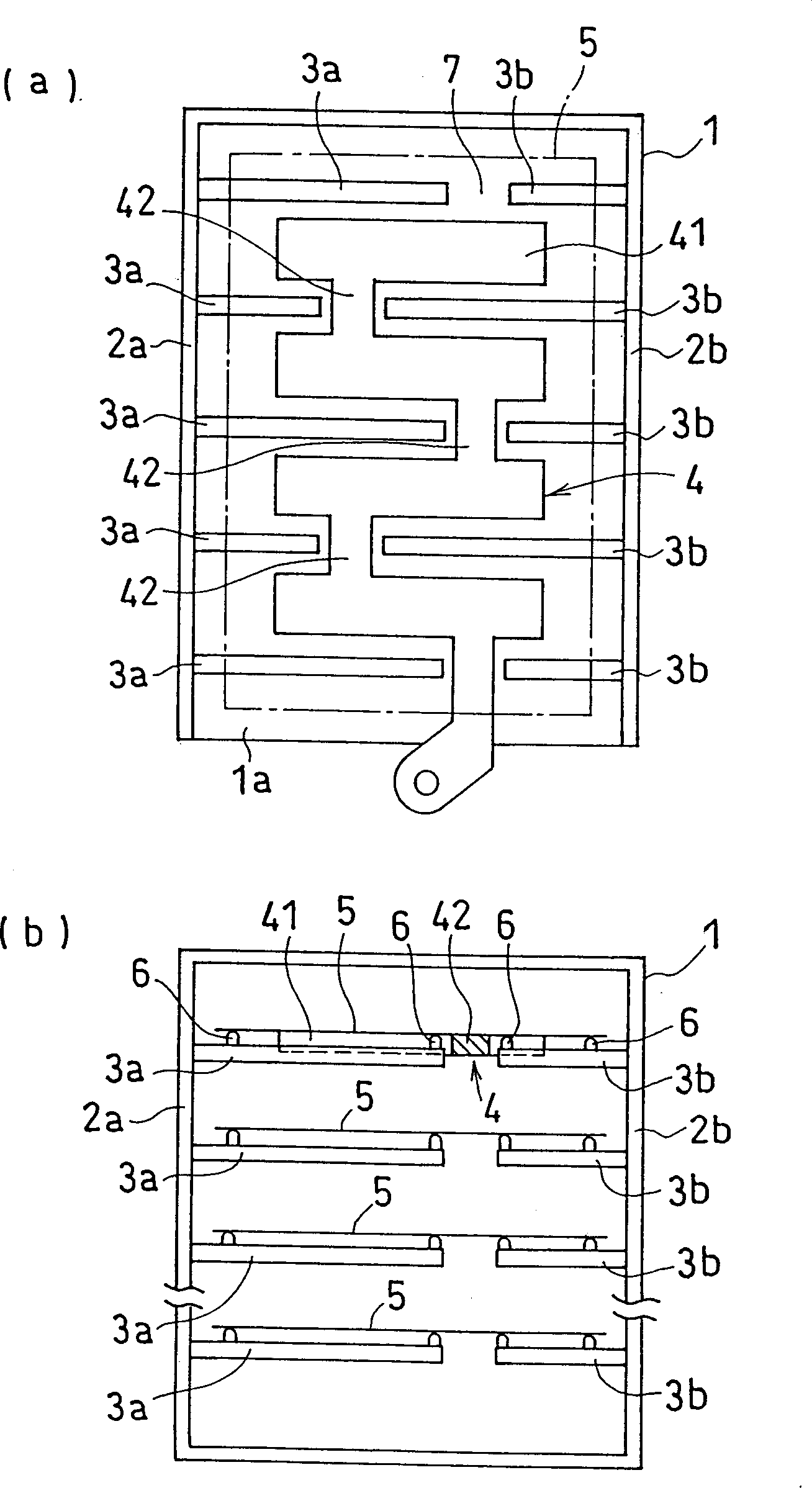

[0036] Figure 1 ~ Figure 2 A moving loading device and a storage device for sheet substrates according to a first embodiment of the present invention are shown.

[0037]This mobile loading device for sheet substrates is a device used in conjunction with other mobile loading devices, and its structure is to extend from the left and right side walls 2a, 2b of the box-shaped box main body 1 as a storage device to opposite directions. A plurality of parallel support members 3a, 3b simultaneously lifts and lowers the robot arm 4 of the mobile loading device 40 inserted into the cassette main body 1 between the support members 3a, 3b to take out and put in the glass substrate 5.

[0038] And, the moving loading device of the sheet substrate like this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com