Apparatus for packing glass plates

A technology of glass plate and packaging device, which is applied in the directions of packaging, transportation and packaging, and packaging of vulnerable items. It can solve the problems that glass plates are easy to break, and achieve the effects of reducing the contact surface pressure, reducing the amount of bending, and inhibiting concave deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0056] 1) Loading objects

[0057]

[0058] 2) Existing example (refer to Figure 7 )

[0059]

[0060]

[0061] 3) Embodiments of the present invention (with reference to Figure 8 )

[0062]

[0063]

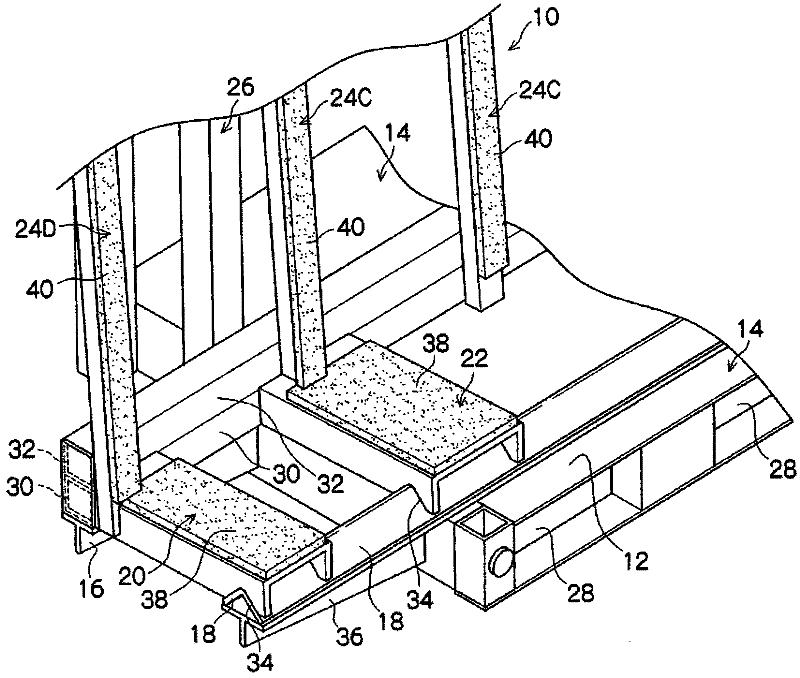

[0064] 4) Embodiments of the present invention (considering the embodiment of the effective area of the bottom shelf (refer to Image 6 ))

[0065]

[0066] From these test results, it can be seen that in the above-mentioned packaging device for glass plates, the surface area of the bottom shelf B arranged near the center of the base member is larger than that of the bottom shelf A arranged on both sides of the base member. surface area to prevent breakage of the glass sheet. Also, by setting the contact surface pressure of the bottom shelf to about 0.119 MPa or lower, breakage of the glass plate can be prevented.

[0067] Explanation of symbols

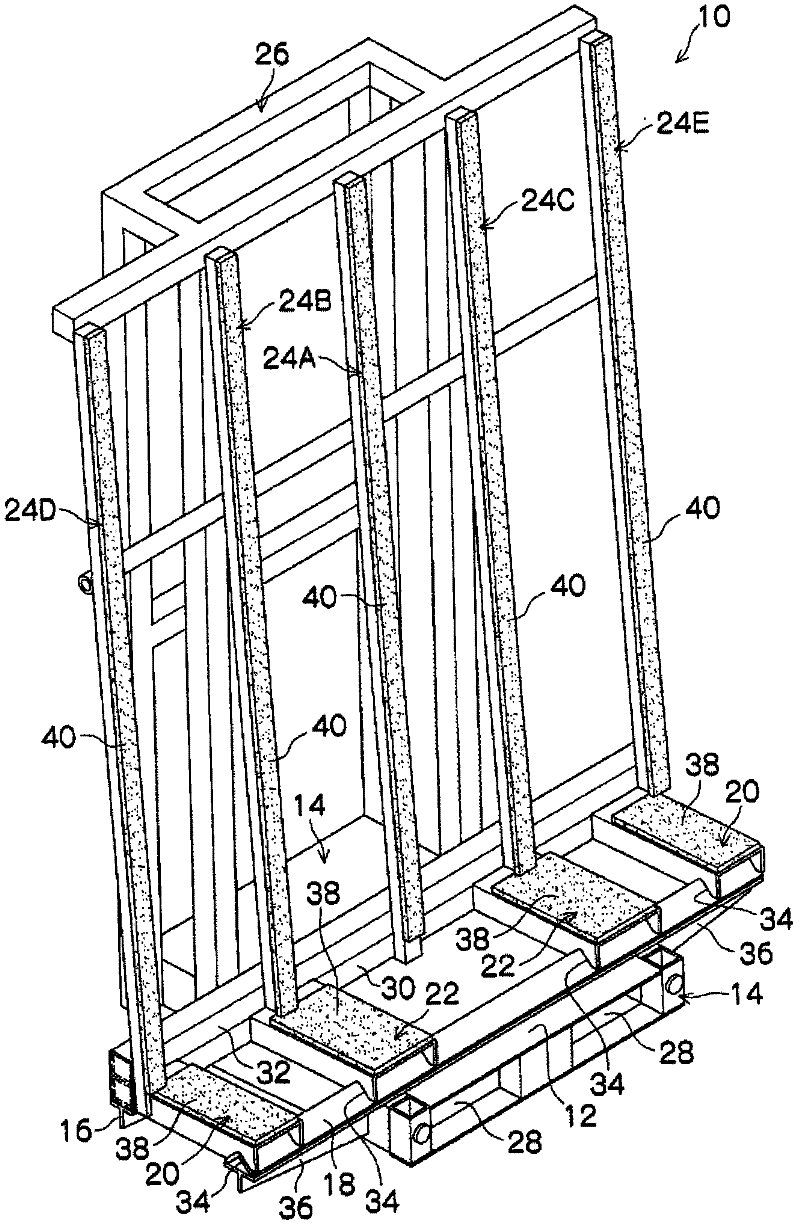

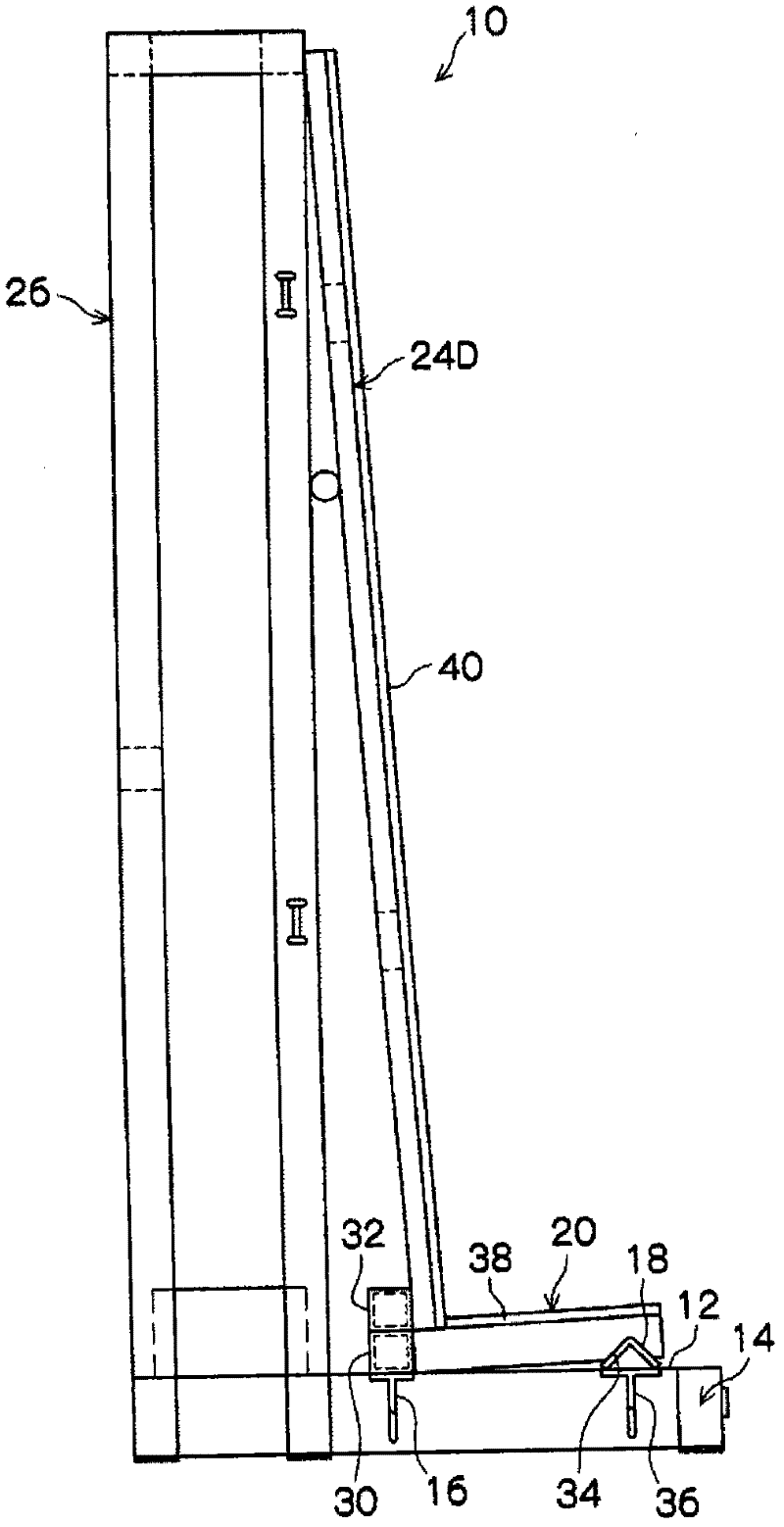

[0068] 10...packing device for glass plates, 12...loading surface, 14...base, 16, 18...base member, 20.....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com