Substrate supporting device

A technology for supporting devices and substrates, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to solve problems such as mutual interference or other influences between devices, inability to perform process operations, and to improve process quality and product yields , the effect of reducing the amount of bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A substrate supporting device according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference numerals.

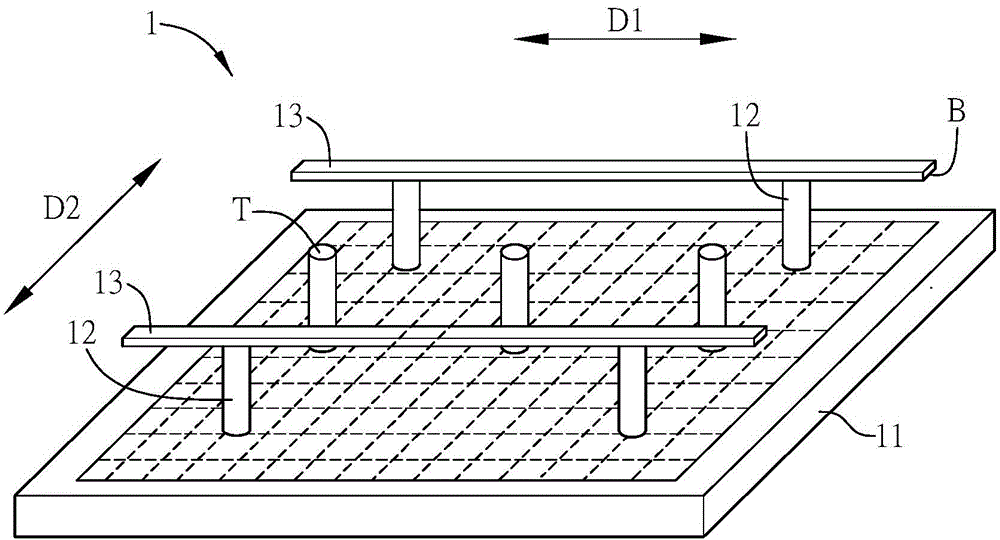

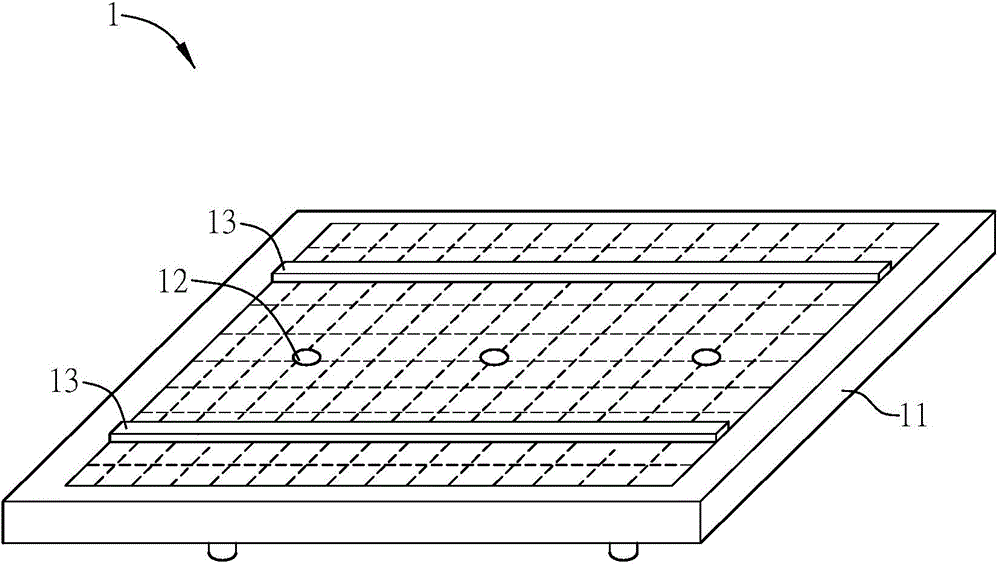

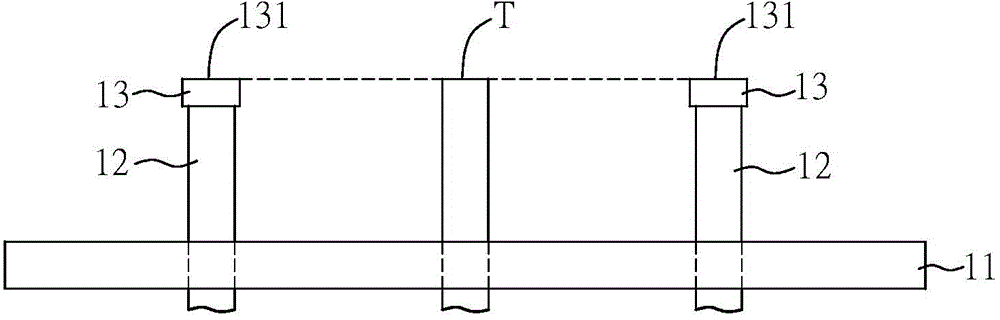

[0019] figure 1 and figure 2 It is a schematic diagram of different states of a substrate supporting device 1 according to an embodiment of the present invention, wherein figure 1 shows the state in which the thimble of the substrate support device 1 is raised, and figure 2 A state in which the ejector pin of the substrate holder 1 is lowered is shown. The thimble in this embodiment can be connected to a driving module (not shown) to move up and down. Since the driving module is not a technical feature of the present invention and is well known to those skilled in the art, it will not be repeated here. The substrate supporting device 1 of this embodiment can be applied to support a substrate, such as a glass substrate, and can be applie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com