Image forming device and paper discharging mechanism thereof

A technology of paper discharge and image, which is applied in the directions of transportation and packaging, sending objects, and thin material handling, etc. It can solve the problem of affecting the stowage performance of the second tray 3 for paper discharge, the inability of paper P to be discharged neatly, and the inability of paper P to be discharged smoothly, etc. problem, to avoid waist collapse, reduce the amount of bending, and enhance the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

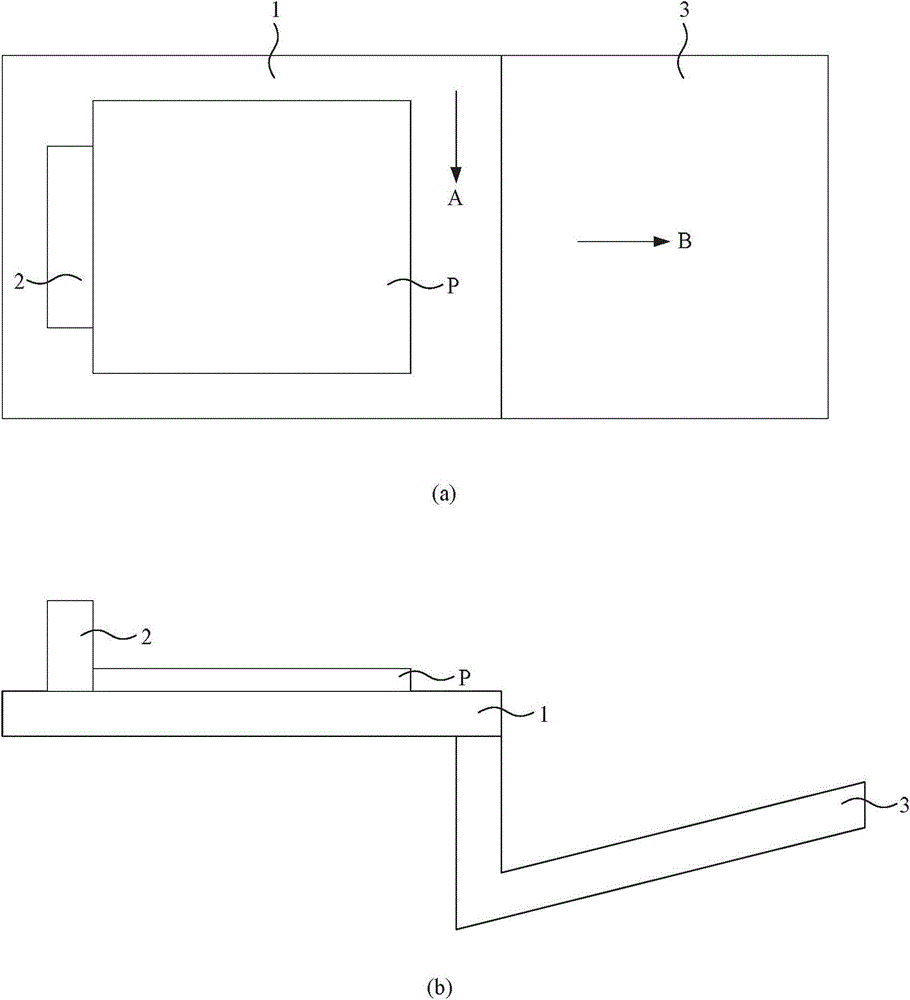

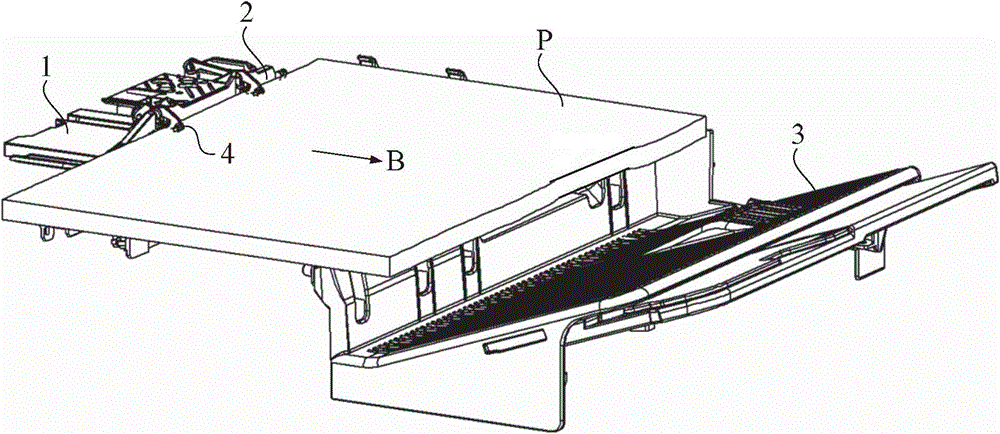

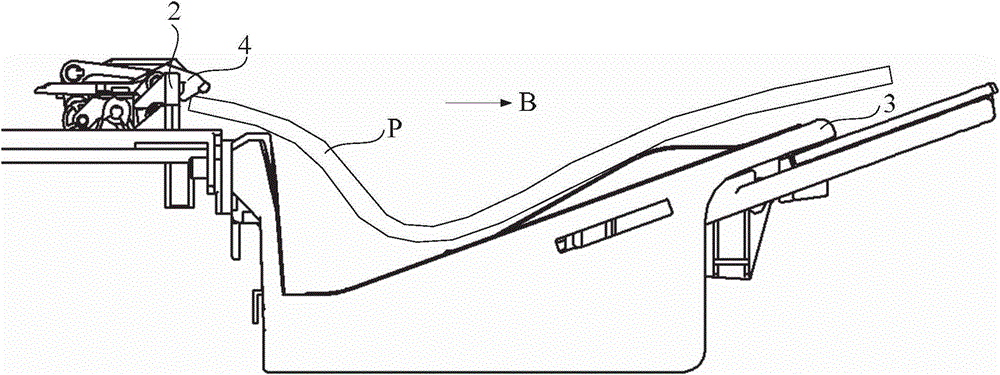

[0044] combine Figure 5 to Figure 6 As shown, the paper discharge mechanism 1 of this embodiment includes: a first tray 10, used to carry the paper P discharged from the paper outlet (not shown) of the image forming apparatus along the discharge direction A; The paper P (the number is one or more) on the first tray 10 is pushed out along the paper discharge direction B; the second tray 30 is located downstream of the first tray 10 along the paper discharge direction B to carry the paper pushed out by the pusher 20, The upstream end of the second tray 30 is lower than the downstream end of the first tray 10; the pressure part 40 is used to press the paper P on the first tray 10; One side of the second tray 30 can support the protrusion 50 when the paper P is discharged along the paper discharge direction B, and forms an arched shape extending along the paper discharge direction B.

[0045] The paper on which the image is formed is discharged from the paper outlet of the image...

no. 2 example

[0062] The difference between the second embodiment and the first embodiment is: as Figure 10 As shown, in the second embodiment, the number of protrusions 50 on the first tray 10 is multiple (two are taken as an example in the figure), and the plurality of protrusions 50 are along the direction perpendicular to the paper discharge direction B (in this paper In the embodiment, the discharge direction A) is also arranged at intervals, and the number of convex portions 60 on the second tray 30 is multiple, and the plurality of convex portions 60 are along the direction perpendicular to the paper discharge direction B (also the discharge direction in this embodiment). A) Arranged at intervals, each protruding portion 50 is located on a straight line along the paper discharge direction B with a corresponding one of the protruding portions 60 .

[0063] Additionally, if Figure 11 As shown, the present invention also provides an image forming device, which includes the paper disc...

no. 3 example

[0065] The difference between the third embodiment and the first and second embodiments is: as Figure 12 As shown, in the third embodiment, the ejection direction A is consistent with the paper ejection direction B; a plurality of protrusions 50 are arranged at intervals along a direction perpendicular to the paper ejection direction B and the ejection direction A, and a plurality of protrusions 60 are also arranged along the direction perpendicular to the ejection direction B; They are arranged at intervals in the direction perpendicular to the paper direction B and the discharge direction A.

[0066] In addition, the present invention also provides an image forming device, which includes the paper discharge mechanism of the third embodiment, and the second tray and the operation panel of the image forming device are not located on the same side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com