Coated sheet cutting method and apparatus

A thin film and coating technology, which is applied in metal processing and other directions, can solve the problems of cracks in the coating layer, difficult cutting conditions, cracks, etc., and achieve the effects of preventing cracks and cracks, reducing the amount of bending, and reducing local deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

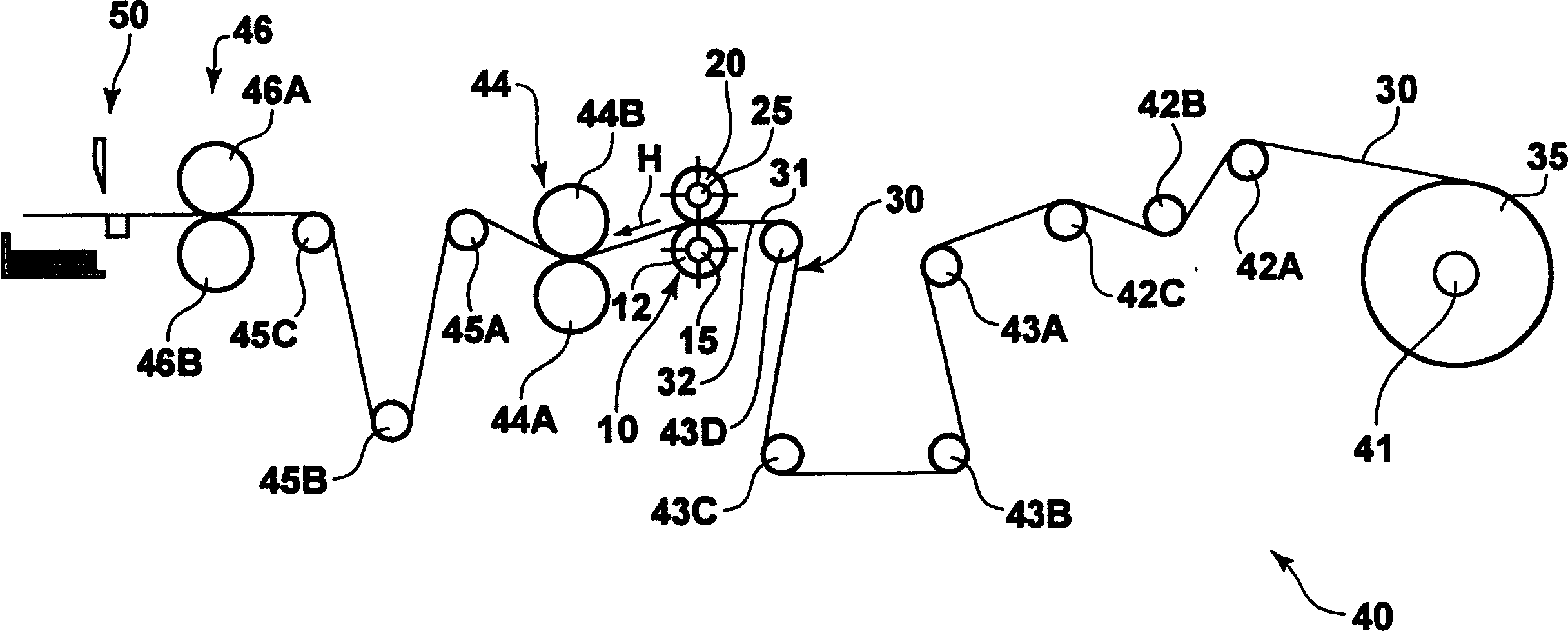

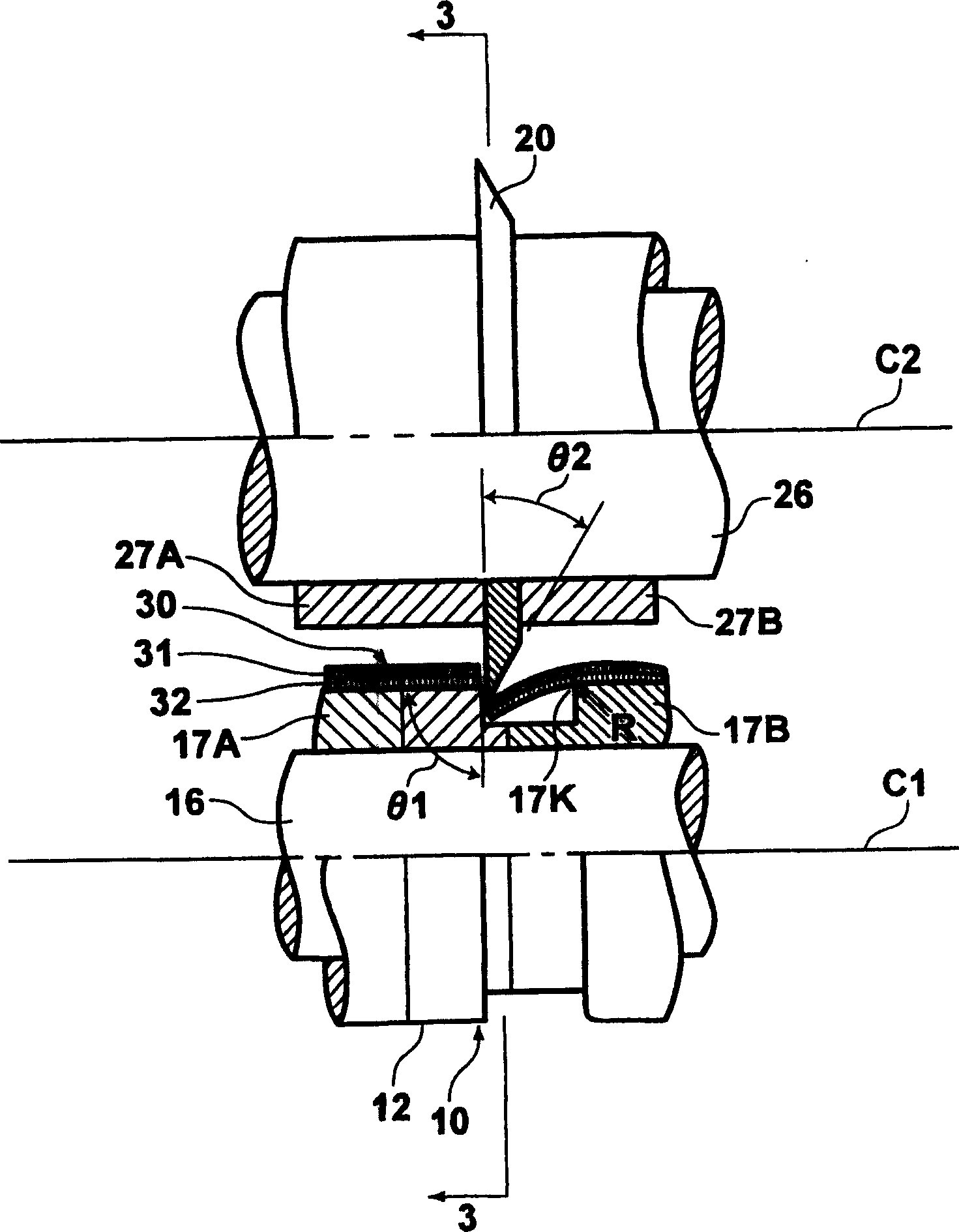

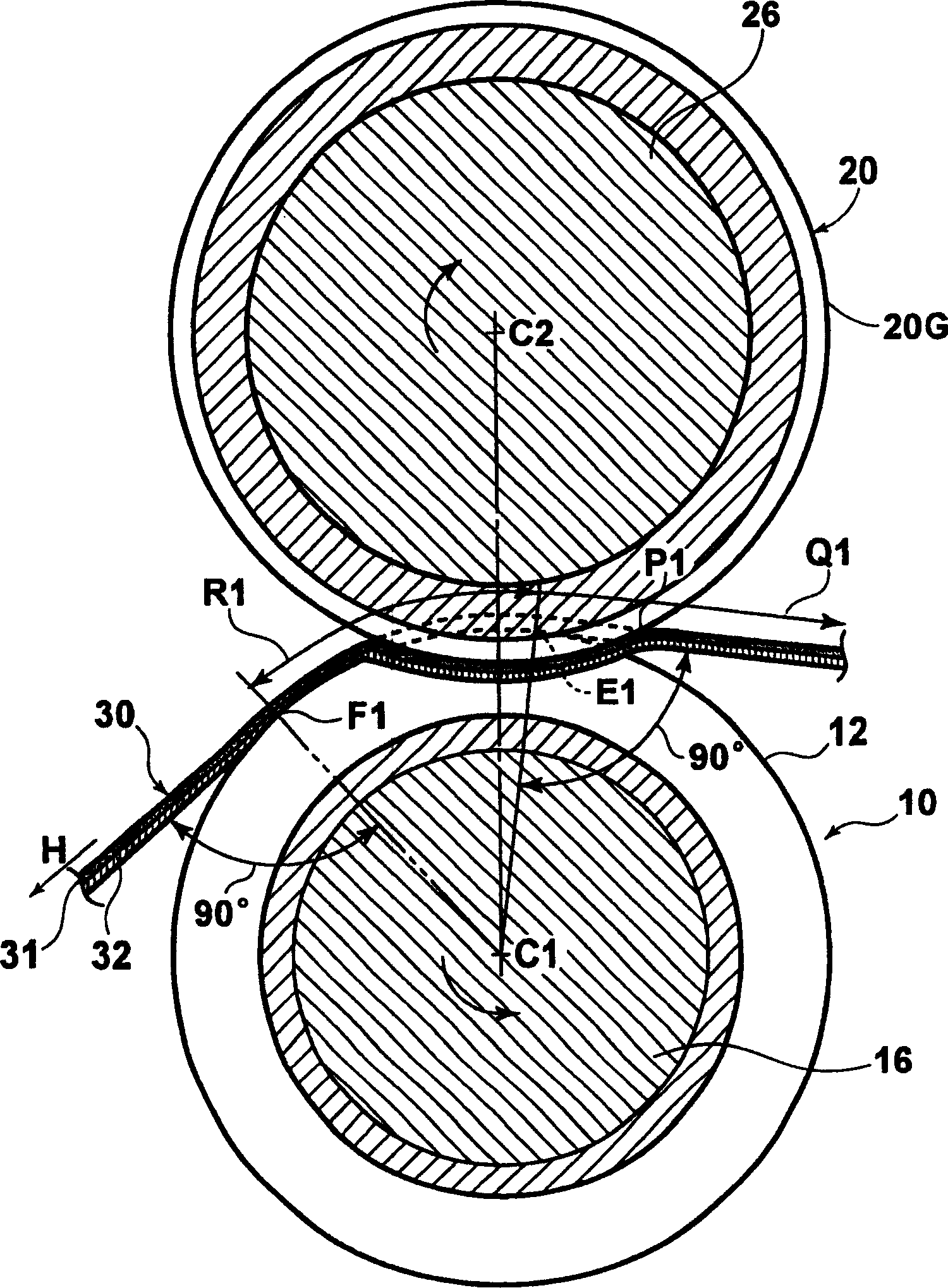

[0027] Hereinafter, a first embodiment of the present invention will be described in detail with reference to the accompanying drawings. figure 1 is a side view showing a schematic structure of a coating sheet cutting device for implementing a coating sheet cutting method according to an embodiment of the present invention; figure 2 yes figure 1 An enlarged partial cross-sectional view of the coating flake cutting device of , showing the positional relationship between the lower cutting blade, the upper cutting blade, and the coating flake; and image 3 is along figure 2Schematic cross-section taken at line 3-3.

[0028] The shown coating flake cutting device comprises a disc-shaped lower cutting blade 10, a lower blade rotating motor 15 for rotating the lower cutting blade 10, a disc-shaped upper cutting blade 20 arranged opposite to the lower cutting blade 10, and a disc-shaped upper cutting blade 20 for rotating the upper cutting blade 10. The upper blade turning motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com