Refrigerant compressor

A compressor and refrigerant technology, applied in mechanical equipment, machinery/engine, liquid variable capacity machinery, etc., can solve the problems of increasing suction loss, reducing refrigeration capacity and refrigeration efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

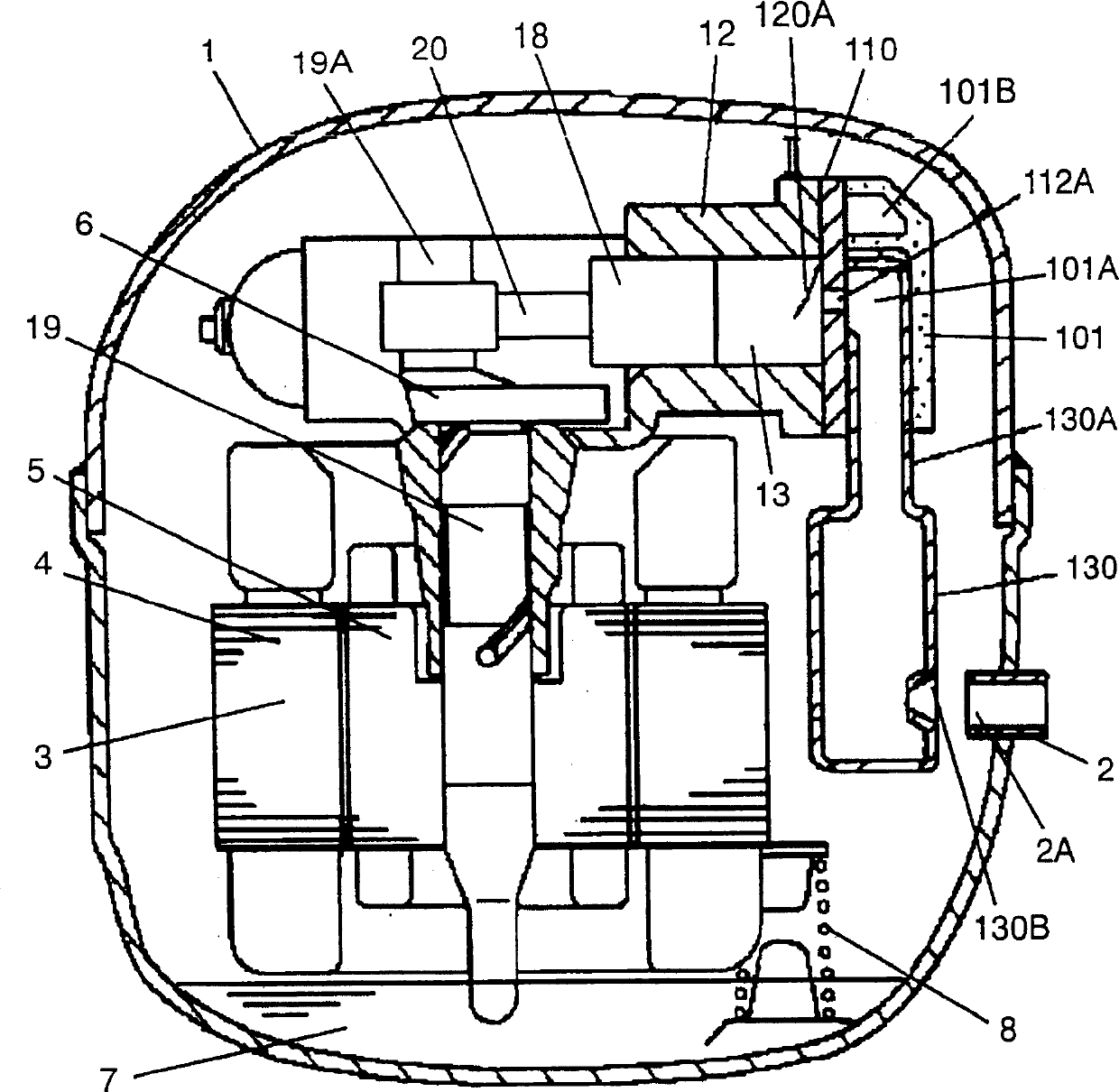

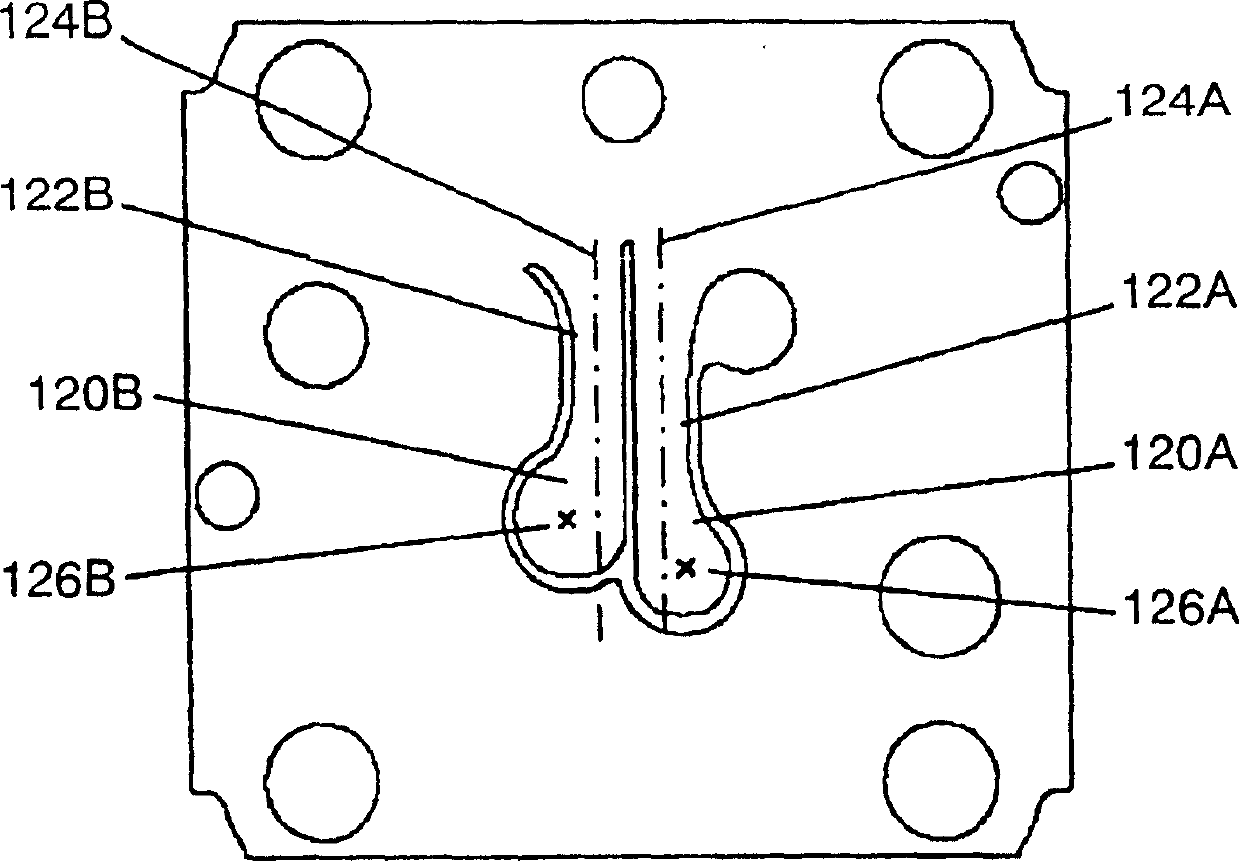

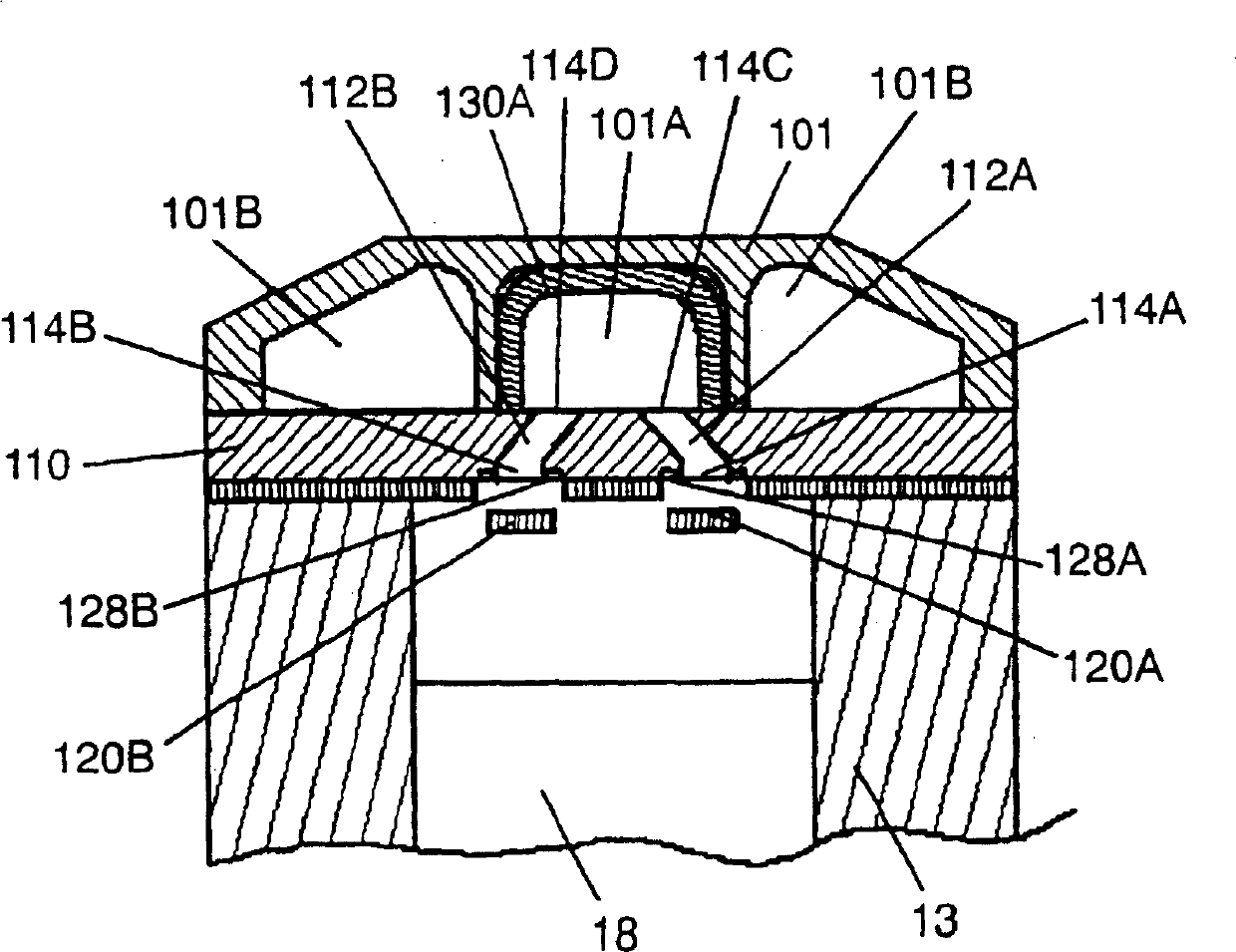

[0017] Fig. 1 is a cross-sectional view of a refrigerant compressor according to an embodiment of the present invention. Fig. 2 is a front view of the suction reed valve. Fig. 3 is a sectional view of a cylinder head.

[0018] One end of the suction pipe 2, that is, an outlet portion 2A, is connected to the airtight container 1, and the other end of the suction pipe 2 is connected to a low-pressure side pipe (not shown) of the refrigeration cycle. A motor 3 constituted by a stator 4 and a rotor 5 drives a compressor 6 . Furthermore, the refrigerating machine oil 7 is stored in the bottom of the airtight container 1 . The coil spring 8 elastically supports the motor 3 and the compression part 6 .

[0019] Compression unit 6 is constituted by cylinder head 101 , cylinder block 12 , valve plate 110 , suction reed valves (hereinafter referred to as valves) 120A, 120B, piston 18 , connecting rod 20 and suction muffler 130 . The cylinder head 101 is formed with an intake space 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com