Elastic running board for running machine

A technology of running boards and treadmills, applied in the field of treadmills, can solve problems such as sports injuries, unfavorable bones and joints, and annoying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

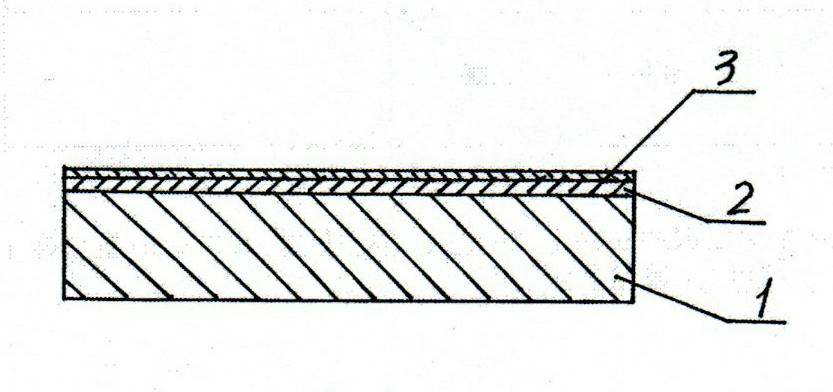

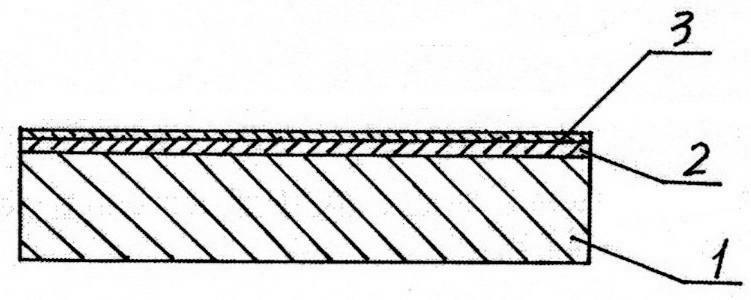

[0019] see figure 1 As shown, an elastic running board for a treadmill is successively bonded by a base plate 1, an elastic layer 2 and a friction layer 3. The material of the elastic layer 2 adopts foam, such as PU foam or EVA foam, and the friction The material of layer 3 is glass fiber reinforced flexible unsaturated polyester resin S-465 or S-628, or epoxy resin toughened and modified by hydroxyl-terminated liquid nitrile rubber CTBN or thermoplastic polyurethane rubber TPU.

[0020] Taking the elastic running board for 18mm home electric treadmill as an example, the explanation is as follows:

[0021] ①. Bottom plate 1 is MDF with a thickness of 12mm, a static bending strength of 50Mpa, an elastic modulus of 2800 Mpa, and a moisture content of 4%.

[0022] ②. The elastic layer 2 is made of EVA foam: the density is 200kg / m3, the hardness is 40°Shore B, and the thickness is 5.8mm.

[0023] ③. Friction layer 3: use glass fiber canvas 220g / ㎡ flexible unsaturated polyest...

Embodiment 2

[0025] Taking the elastic running board for 25mm commercial electric treadmill as an example, the explanation is as follows:

[0026] ①. The bottom plate is made of MDF with a thickness of 18mm, a static bending strength of 45Mpa, an elastic modulus of 2650Mpa, and a moisture content of 4%.

[0027] ②. The elastic layer 2 is made of PU foam: the density is 480kg / m3, the tensile strength is 6.20Mpa, the elongation at break is 330%, the compression deformation of 10% is 1033KPa, the tear strength is 850KN / M, and the thickness is 6.5mm .

[0028] ③. Friction layer 3: use glass fiber canvas 450g / ㎡, epoxy resin E-44 100, (parts by weight, the same below), polyurethane TPU 20, gas phase SiO2120, polyamide 60 (curing agent): the thickness is controlled at 0.5mm .

[0029] The temperature rise of the prepared running board is less than 40°C and the noise is less than 65dB when the running board is continuously operated under a load of 70kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com