Copper alloy rheoforming method

A forming method and technology of copper alloy, applied in the field of copper alloy rheological forming, can solve the problems of difficulty in preparing and forming copper alloy semi-solid blanks, and achieve the effects of compact structure, reduced transshipment, and complex product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

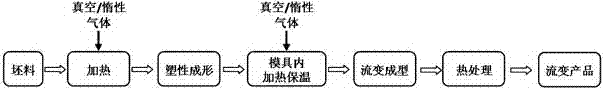

[0025] The copper alloy rheological forming method described in this embodiment is used for forming ZCuSn10 tin bronze products (see figure 1 ), including the following steps:

[0026] (1) Measure the liquid-solid temperature of the semi-solid rheological copper alloy; the alloy in this example is a ZCuSn10 tin bronze alloy, a rectangular material with a size of 40×40×100mm, using differential scanning calorimetry (DSC) The solidus temperature of the alloy is 830℃, and the liquidus temperature is 1020℃;

[0027] (2) Under vacuum (vacuum degree is 10 -2 Pa), heat the ZCuSn10 tin bronze to 450°C, and roll the billet one pass with a reduction of 1mm; then rotate the billet 90° along its axial direction and roll it with a reduction of 1mm; A total of 2 passes are rolled. After the length of the alloy billet after rolling reaches 5%, a plastically deformed ZCuSn10 tin bronze billet will be obtained; before each pass, if the temperature of the billet drops below the recrystallization te...

Embodiment 2

[0034] The copper alloy rheological forming method described in this embodiment is used for forming ZCuSn10 tin bronze products (see figure 1 ), including the following steps:

[0035] (1) Measure the liquid-solid temperature of the semi-solid rheological copper alloy; the alloy in this example is a ZCuSn10 tin bronze alloy, a bar with a size of φ20×60mm, and the alloy is measured by differential scanning calorimetry (DSC) The solidus temperature is 830℃, and the liquidus temperature is 1020℃;

[0036] (2) Under the protection of argon, heat the ZCuSn10 tin bronze to 500℃, and use equal channel angular extrusion to perform 4 passes of equal channel angular extrusion on the blank, and the cumulative deformation reaches 48%; before each pass of extrusion, If the temperature of the billet drops below the recrystallization temperature, the billet needs to be heated to 500°C.

[0037] (3) Put the deformed ZCuSn10 tin bronze into the extrusion die and heat it to 890°C for 45 minutes in a ...

Embodiment 3

[0041] The copper alloy rheological forming method described in this embodiment is used for forming ZCuSn10P1 tin bronze products (see figure 1 ), including the following steps:

[0042] (1) Measure the liquid-solid temperature of the semi-solid rheological copper alloy; the alloy in this example is a ZCuSn10P1 tin bronze alloy, a bar with a size of φ40×60mm, and the alloy is measured by differential scanning calorimetry (DSC) The solidus temperature is 820℃, and the liquidus temperature is 1003℃;

[0043] (2) Under the protection of helium, heat the ZCuSn10 tin bronze to 400℃, and use multiple passes to extrude the blank to φ34×83mm in the first pass, and the cross-sectional deformation is 28%; the second pass Extrude the blank to φ30×106mm, the cross-section deformation is 22%; the third pass extrudes the blank to φ28.5×118mm, the cross-section deformation is 10%; the cumulative cross-section deformation reaches 60%; each pass is extruded Before pressing, if the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com