Container including composite coating

A composite coating and container technology, which is applied in the field of containers containing composite coatings, can solve the problems of insufficient bonding strength, high hardness of ceramic materials, and low particle deposition efficiency, and achieve the effects of high hardness, antibacterial and thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

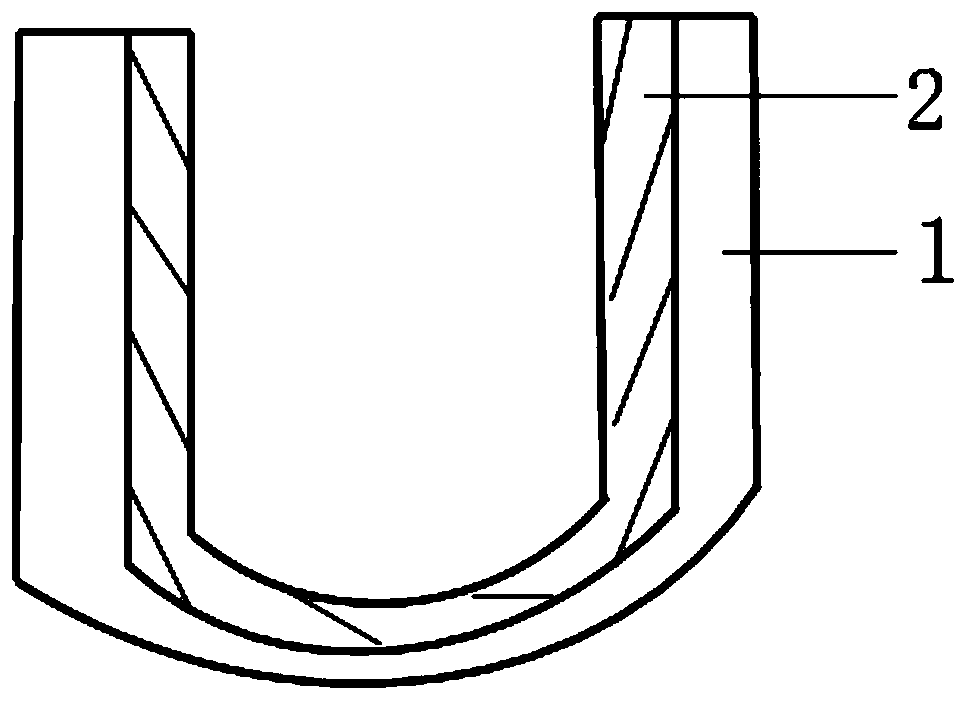

[0024] according to figure 1 The schematic diagram shown is a mixed powder composed of copper powder with an average particle size of 10 μm, silver powder with an average particle size of 18 μm and aluminum oxide powder with an average particle size of 25 μm in a weight ratio of 1:0.1:5, and is heated to 450 °C with Raoult nozzle acceleration. Nitrogen at -550°C is used as the working carrier gas, and the flow rate of the working carrier gas is 0.8m 3 / min, the high-speed working carrier gas accelerates the mixed powder to be sprayed from the spray gun, and the spray pressure is 2.0MPa. It collides with the inner surface of the aluminum alloy pot to form a composite coating with an average thickness of 300 μm, and the inner surface is coated with Aluminum alloy cookware with silver / copper / alumina composite coating. The microhardness (HV0.2) of the composite coating is 78.4, and the wear rate is 3.5×10 -4 mm 3 m -1 ·N -1 , the bonding strength to the aluminum alloy exceeds...

Embodiment 2

[0026] according to figure 1 The schematic diagram shown is a mixed powder composed of copper powder with an average particle size of 18 μm, silver powder with an average particle size of 30 μm, and silicon carbide powder with an average particle size of 35 μm in a weight ratio of 1:0.09:6. Helium at -600°C is used as the working carrier gas, and the flow rate of the working carrier gas is 1.5m 3 / min, the high-speed working carrier gas accelerates the mixed powder to be sprayed from the spray gun, and the spray pressure is 1.8MPa. It collides with the inner surface of the iron pan to form a composite coating with an average thickness of 700μm, and the inner surface is coated with silver. / Copper / SiC composite coated iron cookware. The microhardness (HV0.2) of the composite coating is 124.7, and the wear rate is 6.1×10 -5 mm 3 m -1 ·N -1 , The bonding strength to iron is 45MPa.

Embodiment 3

[0028] according to figure 1 The schematic diagram shown is a mixed powder composed of copper powder with an average particle size of 10 μm, silver powder with an average particle size of 25 μm and zirconia powder with an average particle size of 33 μm in a weight ratio of 1:0.13:8, and is heated to 500 ℃ with the acceleration of a Raoult nozzle. Helium at -600°C is used as the working carrier gas, and the flow rate of the working carrier gas is 1.2m 3 / min, the high-speed working carrier gas accelerates the mixed powder to be sprayed from the spray gun, the spray pressure is 1.5MPa, and hits the inner surface of the stainless steel thermos cup to form a composite coating with an average thickness of 500μm, and the inner surface is coated with silver / Copper / zirconia composite coating thermos cup. The microhardness (HV0.2) of the composite coating is 82.5, and the wear rate is 8.7×10 -5 mm 3 m -1 ·N -1 , The bonding strength to stainless steel is 48MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com