Metal surface treatment spiral roller and treating device and method

A metal surface treatment and treatment method technology, which is applied in the field of metal surface treatment helical rollers and its treatment device, can solve the problems of complex treatment process and low efficiency of metal surface rust removal treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

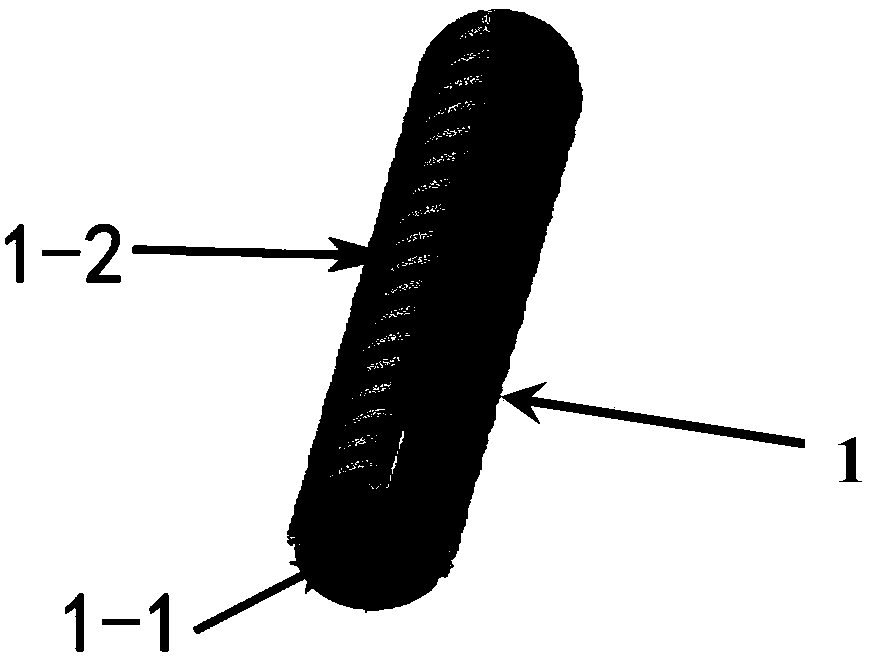

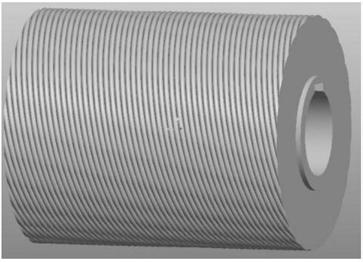

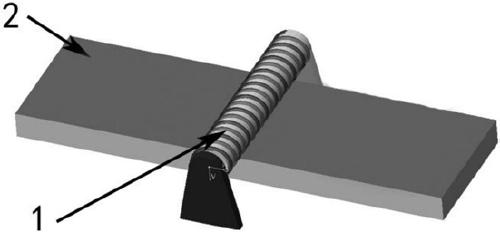

[0081] A spiral roller for metal surface treatment, comprising a roller body 1-1 and a helical wire processing blade 1-2, the surface of the roller body 1-1 is provided with a helical wire processing blade 1-2;

[0082] The outer surface of the roller body is a cylinder surface, which is a body of revolution; the helix of the helix processing blade is two helixes; there are grooves between the helixes, and the structure diagram is shown in figure 1 , the schematic diagram of its three-dimensional structure is shown in figure 2 .

[0083] The helical processing blade is three-dimensional, and its cross section is semicircular.

[0084] The grooves can allow cooling liquid to enter, and at the same time, oxide scales or tiny metal shavings processed from the surface of the processed metal or metal components can be discharged from the grooves.

[0085] The material of the metal surface treated helical roller is metal.

[0086] Holes are provided at the center of the bottom s...

Embodiment 2

[0113] A spiral roller for metal surface treatment, comprising a roller body and a helical wire processing blade, the surface of the roller body is provided with a helical wire processing blade;

[0114] The outer surface of the roller body is the surface of a cylinder, which is a body of revolution; the helix of the helix processing blade is two helixes; grooves are formed between the helixes.

[0115] The helical processing blade is three-dimensional, and its cross section is wedge-shaped.

[0116] The grooves can allow cooling liquid to enter, and at the same time, oxide scales or tiny metal shavings processed from the surface of the processed metal or metal components can be discharged from the grooves.

[0117] The material of the metal surface treated helical roller is ceramics.

[0118] Protruding cylinders are arranged at the center of the bottom surface of both ends of the metal surface treatment spiral roller, the purpose is to fix the metal surface treatment spiral...

Embodiment 3

[0134] A spiral roller for metal surface treatment, comprising a roller body and a helical wire processing blade, the surface of the roller body is provided with a helical wire processing blade;

[0135] The outer surface of the roller body is a cylinder surface, which is a body of revolution; the helix of the helix processing blade is three helixes; grooves are formed between the helixes.

[0136] The spiral processing blade is three-dimensional, and its cross section is trapezoidal.

[0137] The grooves can allow cooling liquid to enter, and at the same time, oxide scales or tiny metal shavings processed from the surface of the processed metal or metal components can be discharged from the grooves.

[0138] The material of the metal surface treated helical roller is metal.

[0139] Holes are provided at the center of the bottom surface of both ends of the metal surface treatment helical roller, the purpose is to fix the metal surface treatment helical roller on the metal su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com