Radome installation bogie based on array absorption unit

An adsorption unit and installation trolley technology, which is applied in aircraft assembly, ground installation, transportation and packaging, etc., can solve problems such as low efficiency, low attitude adjustment accuracy, and difficulty in realizing multi-degree-of-freedom collaborative control, so as to improve safety. , Improve control accuracy and reduce the effect of local deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

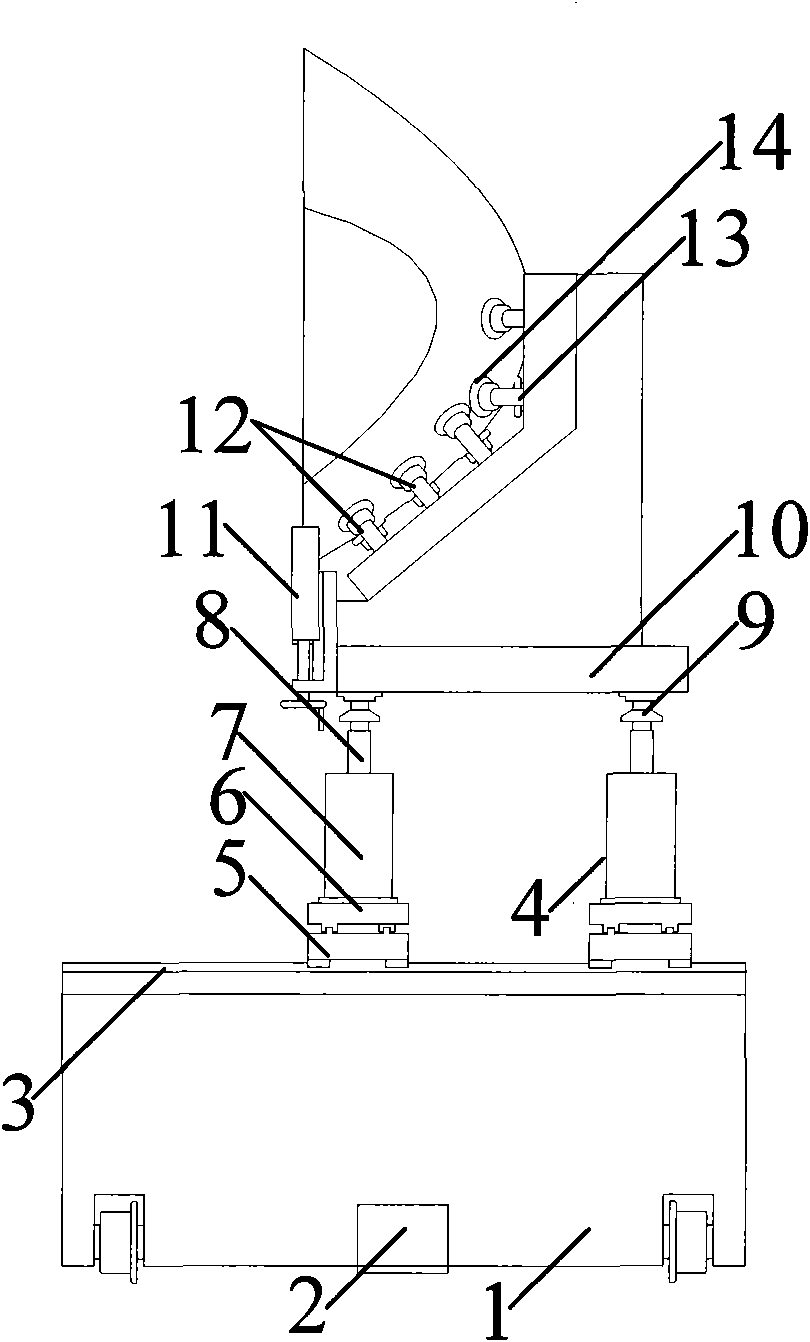

[0010] The radome installation trolley based on the array adsorption unit mainly uses a flexible fixture component-three-coordinate positioner, a multi-point array vacuum adsorption tool composed of multiple three-coordinate positioners, which can be generated to fully conform to the radome profile. The support lattice is evenly distributed. When the shape of the radome changes, the shape of the tooling can be automatically adjusted to adapt to different radome structures and positioning and clamping requirements, with great flexibility. In addition, the three-coordinate positioner for three-coordinate attitude adjustment at the bottom of the device can move in three directions of X, Y, and Z. Multiple three-coordinate three-coordinate positioner units for three-coordinate attitude adjustment form a parallel structure platform, plus the above-mentioned array vacuum adsorption flexibility The bracket can realize the 6-DOF attitude adjustment of the radome.

[0011] As shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com