A prefabricated assembly type seismic toughness reinforced concrete frame structure and its construction method

A technology for reinforced concrete and reinforced concrete columns, which is applied in the field of prefabricated seismically ductile reinforced concrete frame structures and construction, can solve problems such as collapse, cracks in concrete components, and large plastic deformation, and achieves convenient replacement and maintenance, small residual deformation, and residual Small displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

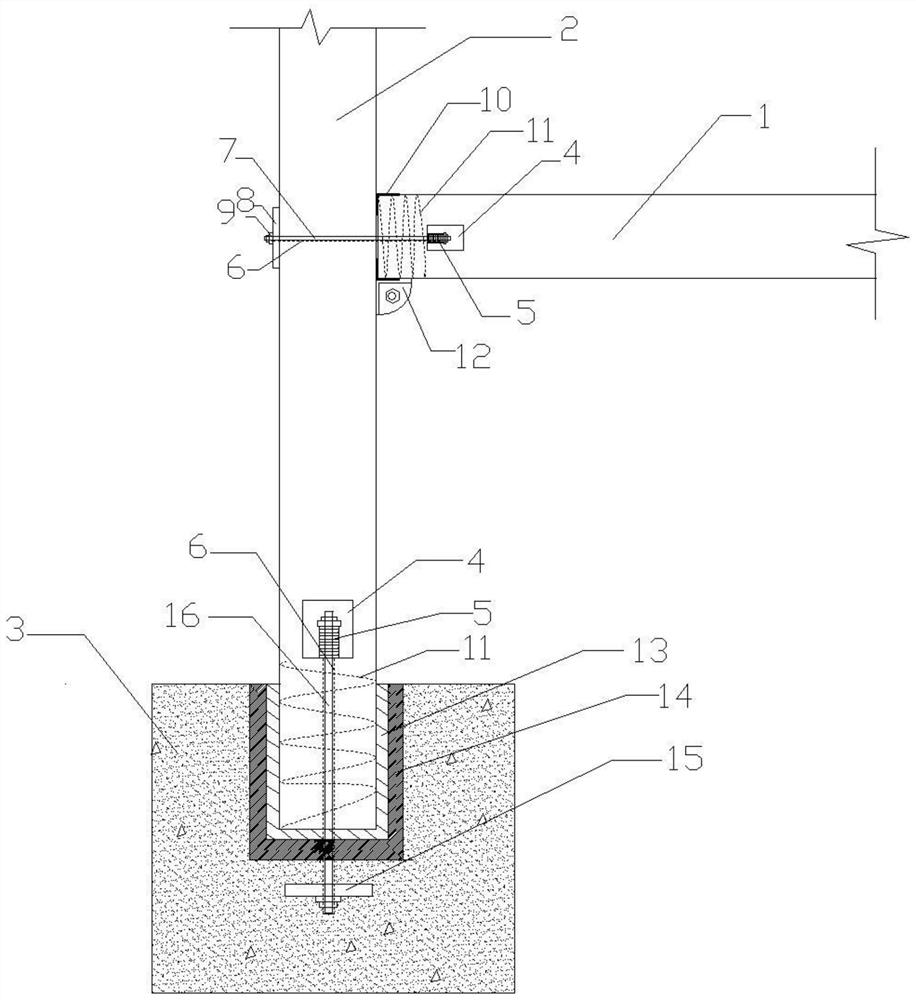

[0037] See attached figure 1 , the embodiment of the present invention discloses a prefabricated assembled anti-seismic ductile reinforced concrete frame structure, which is constructed on a concrete foundation 3, including: reinforced concrete columns 2, anchor rods 16, reinforced concrete beams 1, tie rods 7 and dampers 12;

[0038] The reinforced concrete column 2 is vertically arranged, and the bottom end is inserted into the groove formed on the top surface of the concrete foundation 3, and the space between the reinforced concrete column 2 and the groove is filled with elastic and stretchable material 14; the reinforced concrete column 2 is close to the end of the concrete foundation 3 A hole 4 is opened;

[0039] The anchor rod 16 axially passes through the interior of the reinforced concrete column 2, the top end passes through the hole 4 of the reinforced concrete column 2 and is fixed after being set with a disc spring group 5, and the other end passes through the bo...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that the position of the hole 4 at the end of the column foot of the reinforced concrete column 2 is different. The position of the hole 4 is still the front and rear sides of the end of the beam; the end of the reinforced concrete column 2 can be replaced by an externally installed stirrup in order to ensure that the reinforced concrete column is not damaged by bending. Steel pipe protection. Adaptive selection can be made according to specific conditions during construction, with the purpose of making the construction method more convenient.

Embodiment 3

[0057] The embodiment of the present invention discloses a method for constructing an earthquake-resistant ductile reinforced concrete column and a steel concrete beam frame, including the following steps:

[0058] S1. Reinforced concrete beam 1 and reinforced concrete column 2 are provided with reserved holes 6 and 4 during prefabrication;

[0059] S2. Pre-embed and fix one end of the anchor rod 16 in the concrete foundation 3, design and reserve the size of the groove, and then pour the concrete foundation 3 to form. After the concrete foundation 3 reaches the final setting stage, fill the groove around the groove successively. sexual material 14;

[0060] S3. Put the reinforced concrete column 2 through the protruding end of the pre-embedded anchor rod 16 and put it into the reserved groove of the concrete foundation 3, install and fix the disc spring group 5 on the anchor rod 16 extending into the hole 4 top;

[0061] S4. Insert the tie rod 7 at the beam-column node into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com