Pier column prefabrication splicing building technology

A pier column and construction method technology, applied in the field of pier column prefabricated splicing construction, can solve problems such as long period and inconvenient construction, and achieve the effects of easing the tight construction period, easy inspection of finished products, and conducive to scientific management

Active Publication Date: 2009-05-13

NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY +1

View PDF0 Cites 52 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Such construction is inconvenient, the period is long, and variou

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

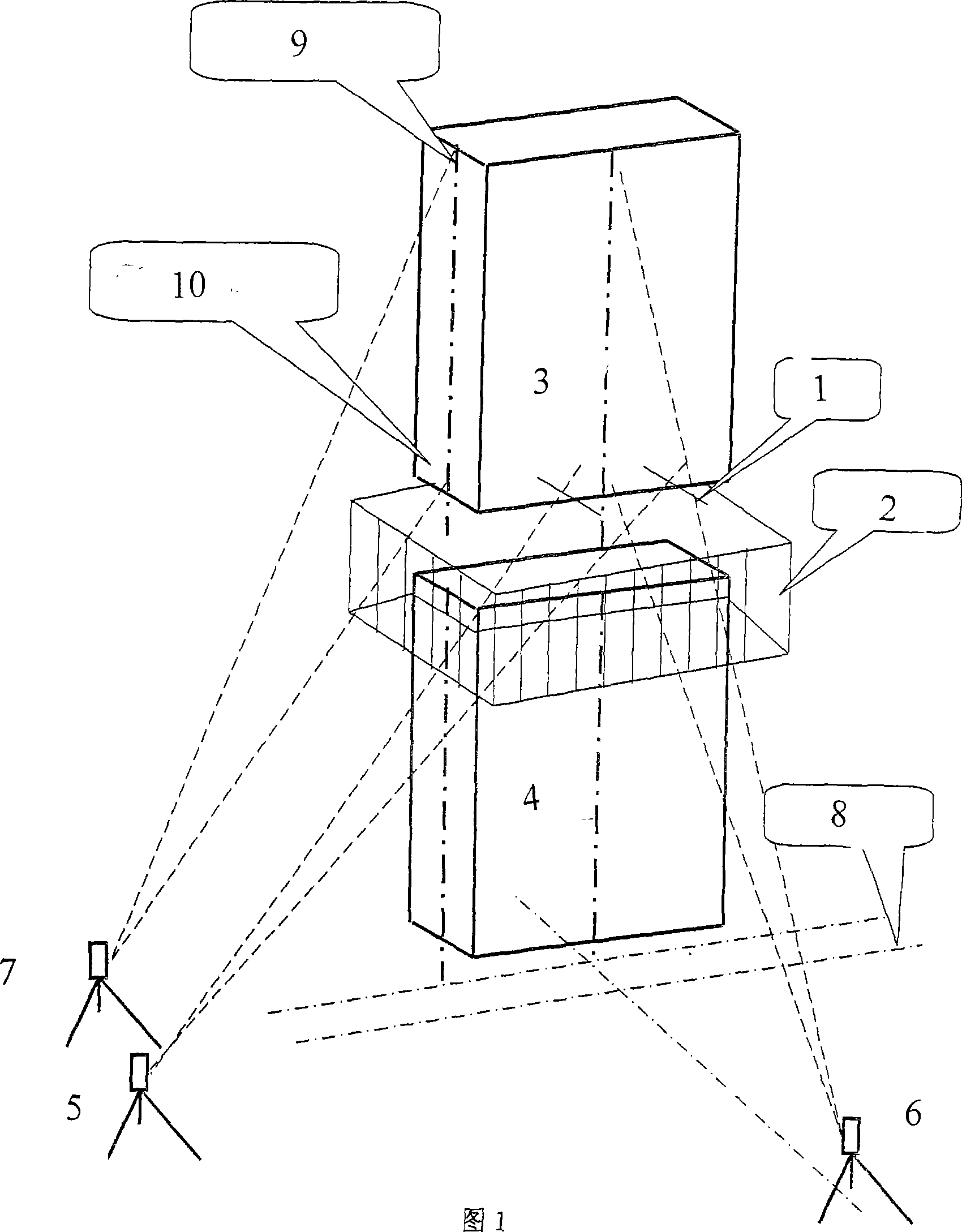

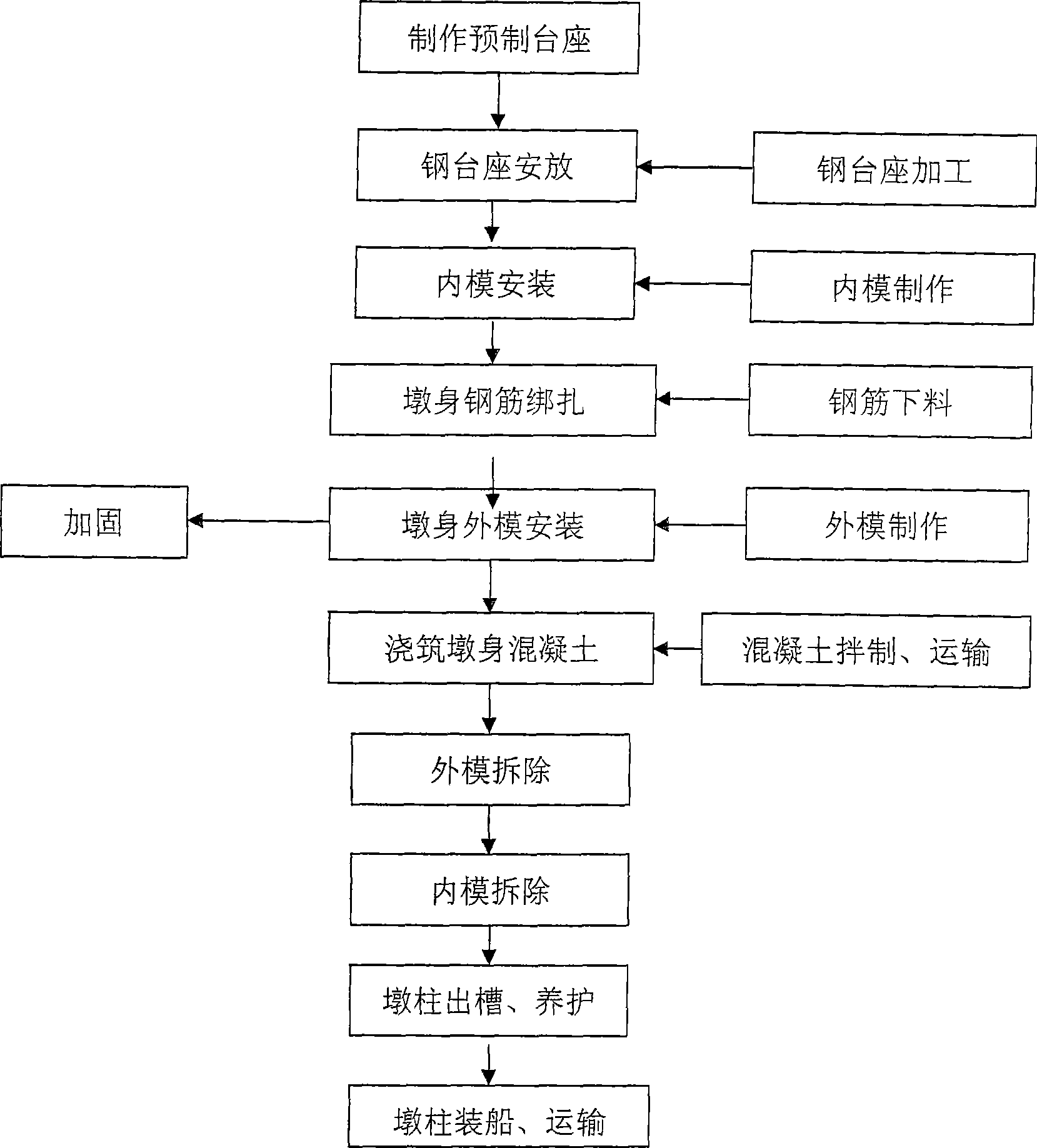

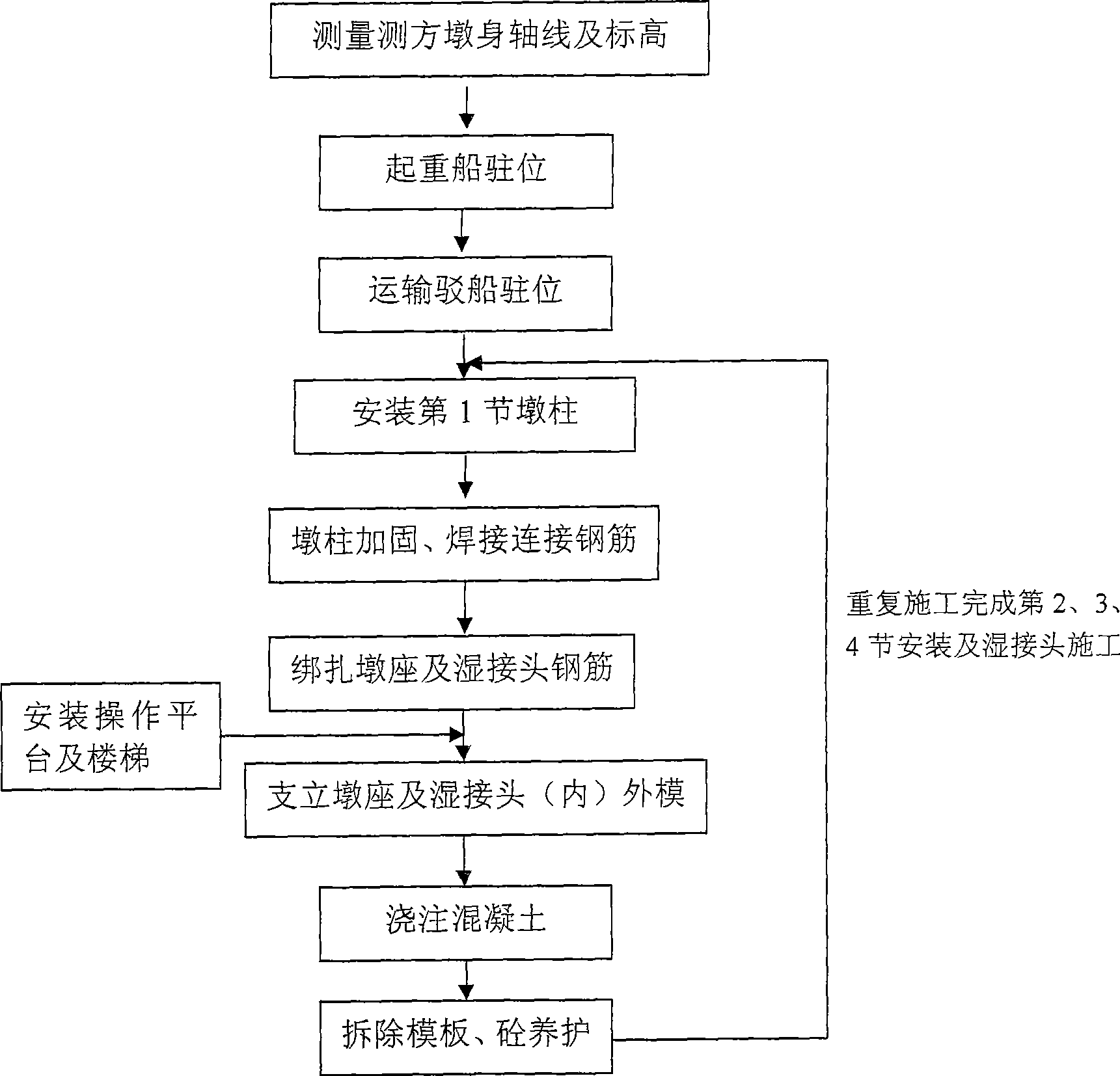

The invention provides a pier column pre-casting splicing construction technique working method, which is characterized in that: on a land construction site, a pier body of the whole bridge pier is pre-cast by segments, pier body end heads of each segment are buried with outwardly-extending reinforcement bars, and all segments are transferred to the pier construction site for pier assembly. The working method has the advantages of having light bridge piers, reducing the number of projects, saving manpower, lowering construction costs, having good construction quality and quick construction, solving the problems of reliability, safety, anti-crack property and durability between pier columns pre-cast by segments and between the pier columns and a bearing platform connecting structure, reducing the influence of natural conditions on construction period, reducing construction cost and construction risk, reducing the number of cast-in-situ concrete and equipment such as a hoisting machine and the like and effectively saving cost. Due to the advantages of the splicing type bridge pier and the development of various high strength concrete materials in recent years, the working method is applied to water bridges with large scale, multiple bridge spans, adverse natural environment, and difficult construction due to the influence of wind, wave, current, rain and fog.

Description

technical field [0001] The invention belongs to the construction of bridge piers, in particular to a prefabricated splicing construction method of pier columns. technical background [0002] In the past, the traditional construction method of bridge piers was to place steel sleeves and cast-in-place reinforced concrete on the spot in the water, and build them up bit by bit in the water. Such construction is inconvenient, the period is long, and various quality problems will be caused by the influence of the weather. Contents of the invention [0003] The invention provides a prefabricated splicing construction method of pier columns. It is based on the fact that in the past ten years, with the continuous emergence of new materials and the development of bridge design technology, the pier structure has developed towards the direction of light weight, high strength and rapid construction. The development of high-toughness, high-density and high-durability concrete provides ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E01D21/00E01D19/02

Inventor 陈重陈平张宝智刘雅清祝业浩高雷殷天军闫明吉刘志军陈健刘伟李建明卞蜀陵

Owner NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com