Automatic leveling system and method for six-point support bridging platform

A working platform and automatic leveling technology, which is applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of increased leveling complexity, poor environmental adaptability, and prolonged leveling time, achieving strong environmental adaptability and The effect of safety, good leveling accuracy and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

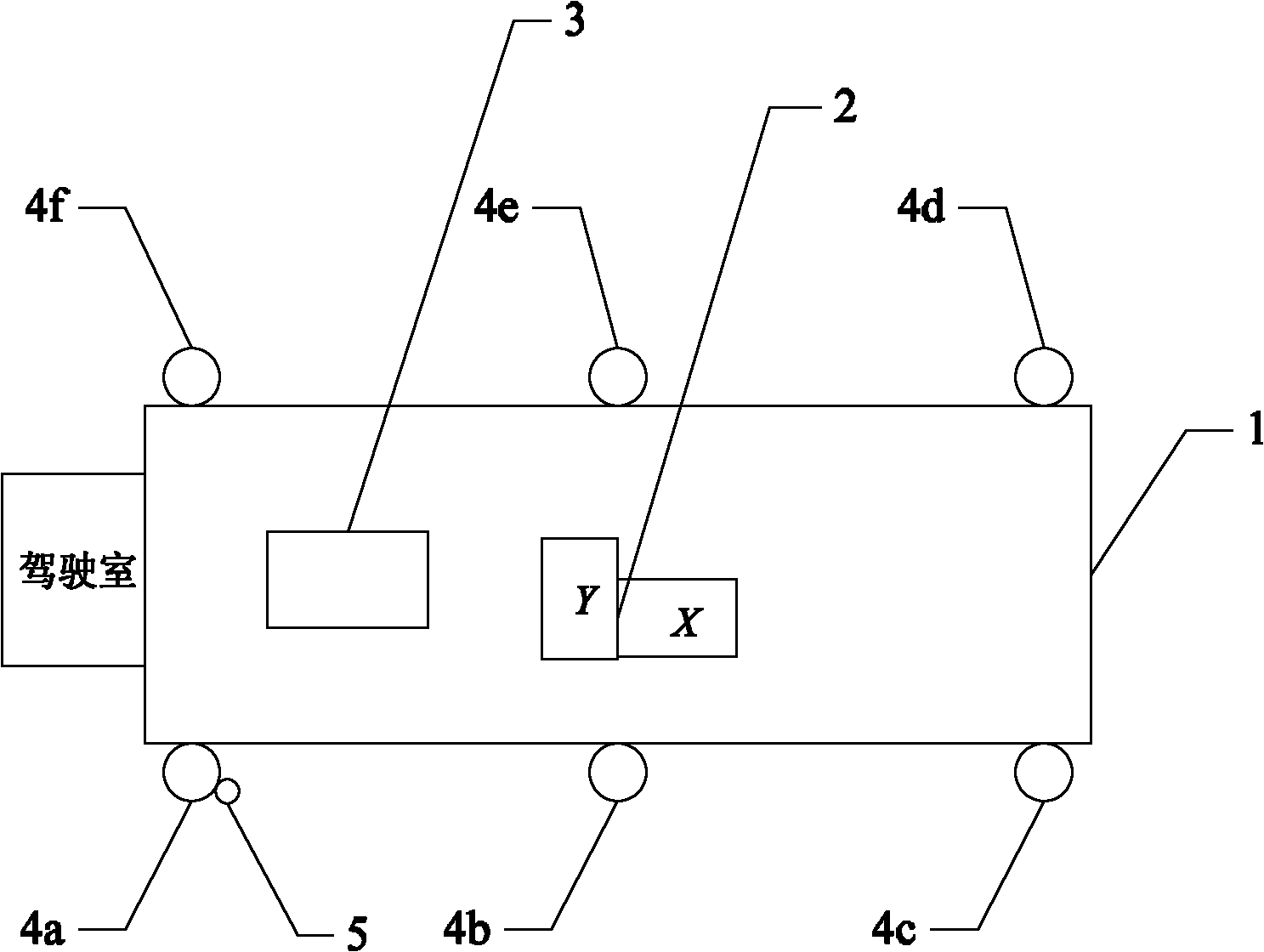

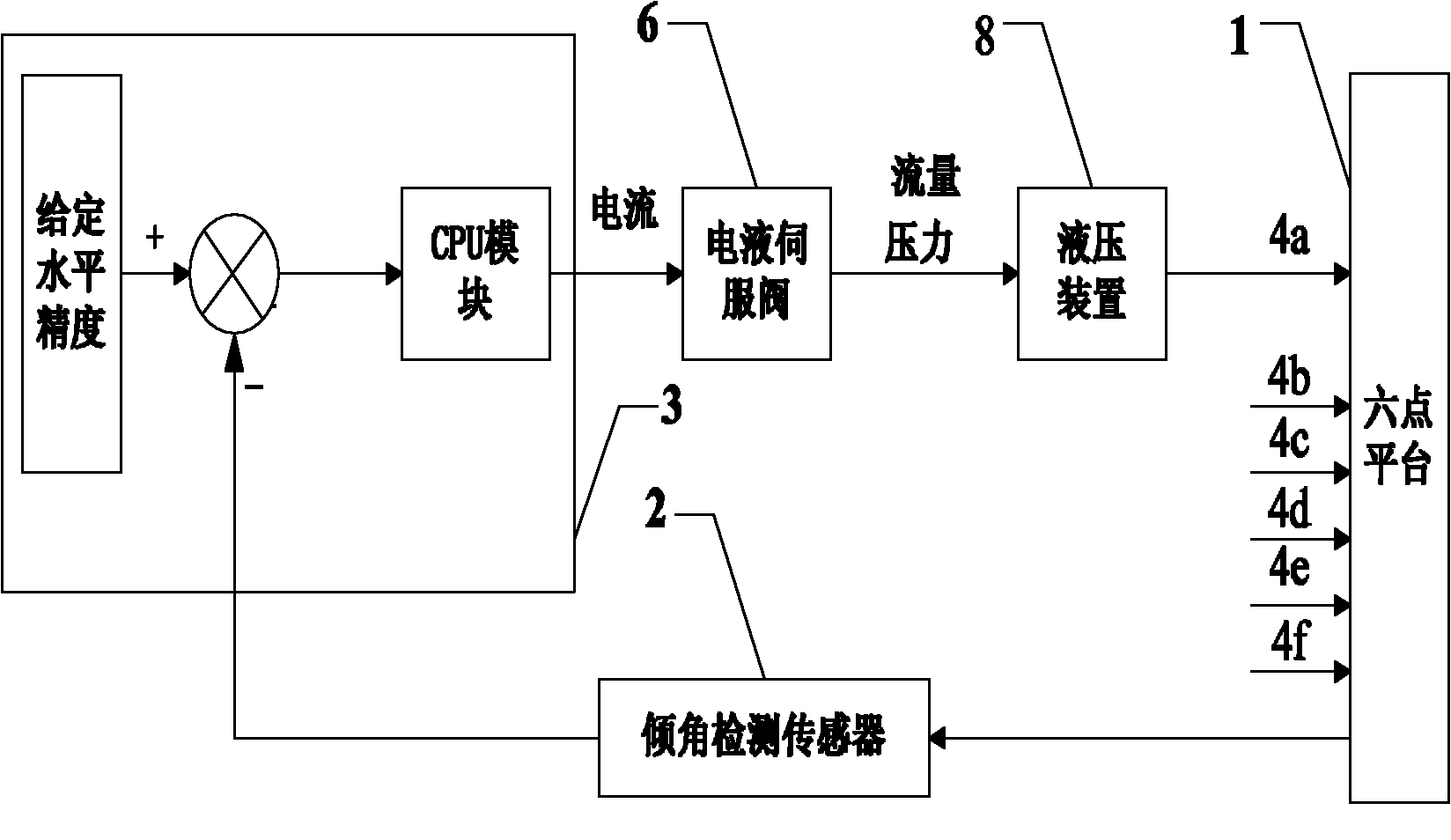

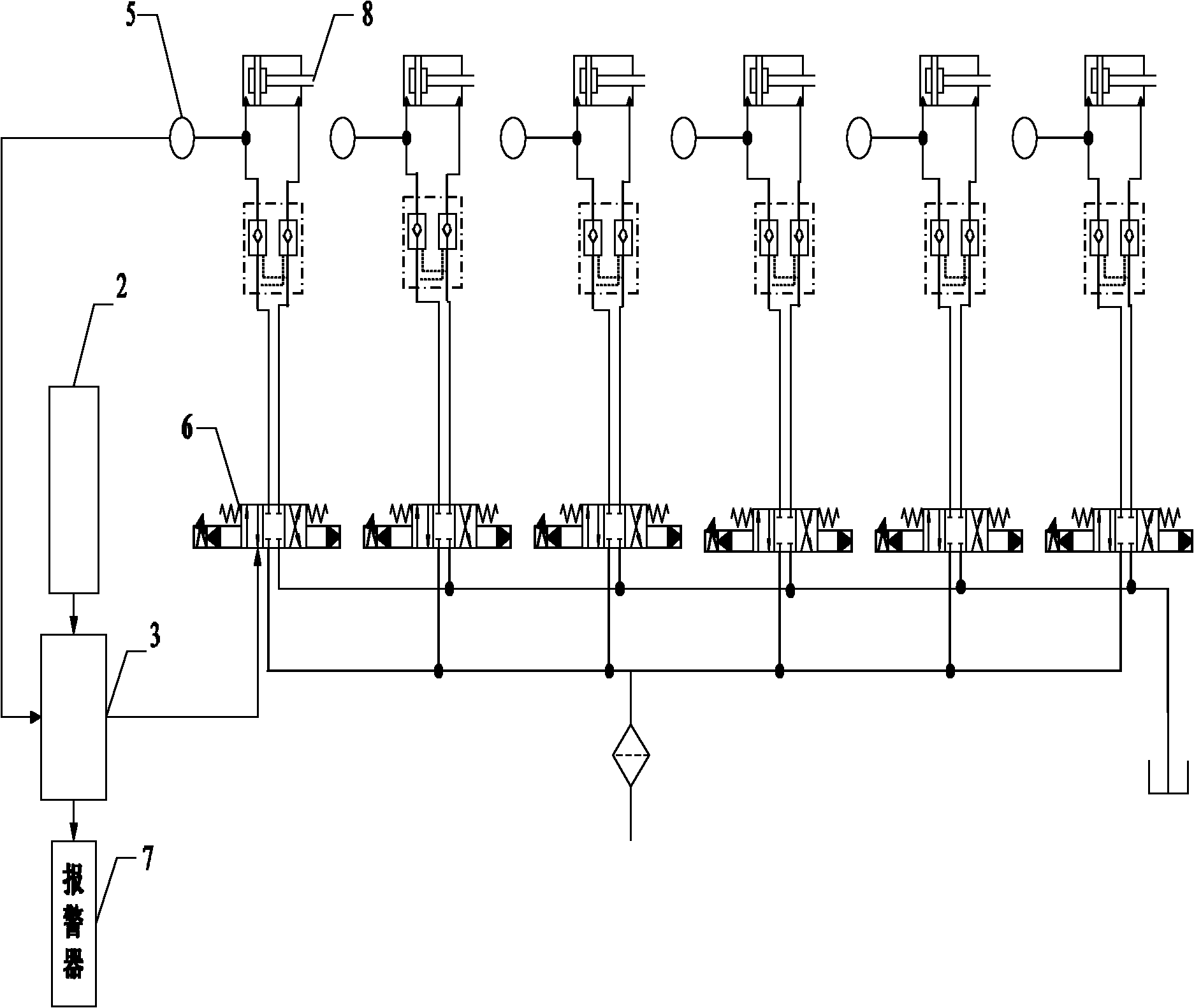

[0013] Such as figure 1 As shown, the six-point support bridging work platform automatic leveling system of the present invention includes a work chassis vehicle platform 1, a biaxial inclination sensor 2, a controller 3, two forward legs 4a and 4f, two middle auxiliary legs 4b and 4e, two backward legs 4c and 4d, a pressure sensor 5, an electro-hydraulic servo valve 6 and an alarm 7 etc. are composed. Wherein, the six supporting legs of the forward supporting legs 4a and 4f, the middle auxiliary supporting legs 4b and 4e, and the rearward supporting legs 4c and 4d are respectively fixed on the two sides of the working chassis platform 1. Both the biaxial inclination sensor 2 and the controller 3 are fixed on the operating chassis platform 1, and the biaxial inclination sensor 2 is vertically fixed on the operating chassis platform 1 to detect the X direction and the Y direction of the operating chassis platform 1. inclination. A pressure sensor 5 is set on each leg, figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com