Saturated sandstone layer engaged water stop pile supporting system and construction method thereof

A construction method and technology of water-stop piles, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as broken piles, difficult construction, collapsed holes, etc., to eliminate water leakage, improve molding quality, and ensure construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

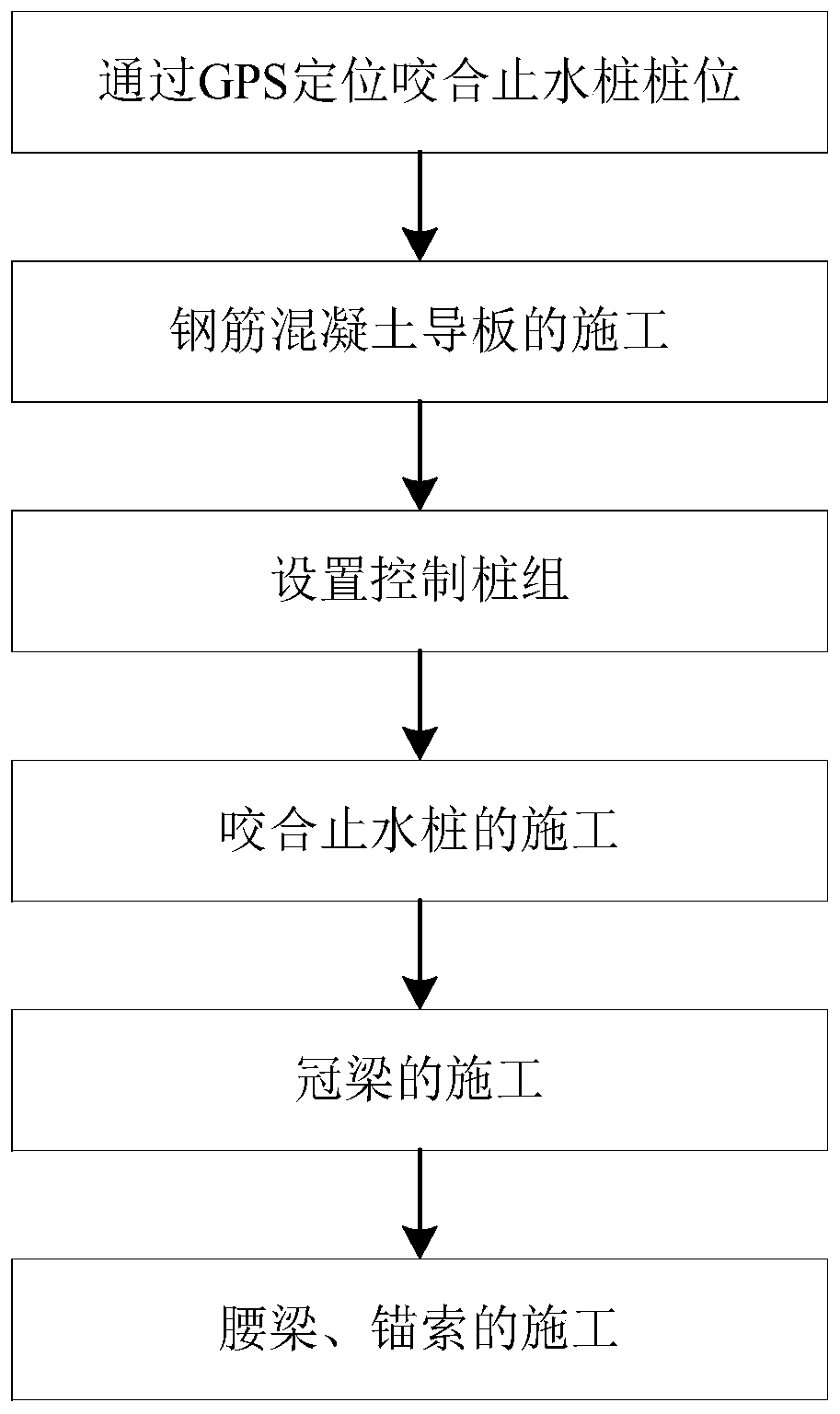

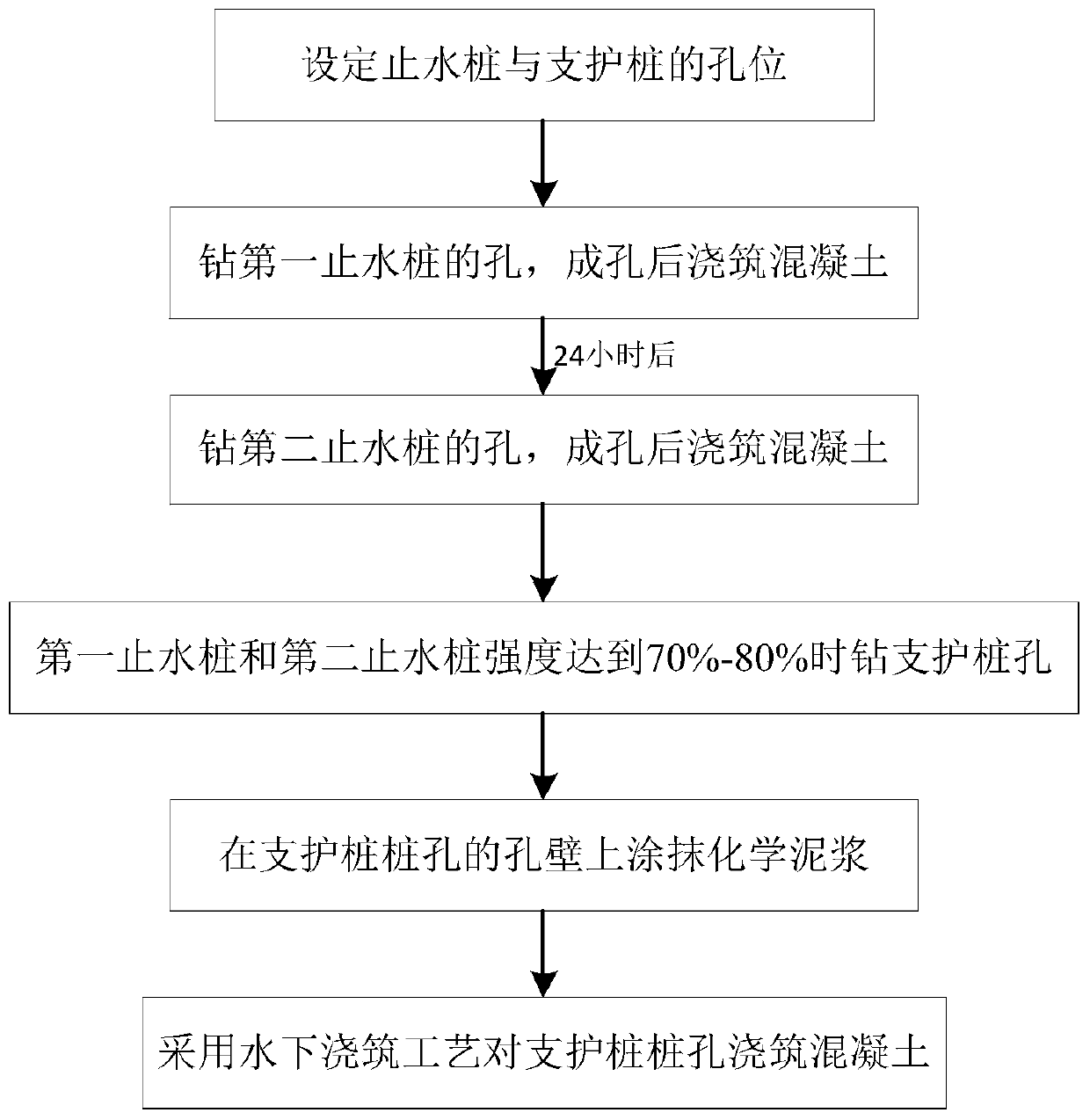

[0047] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

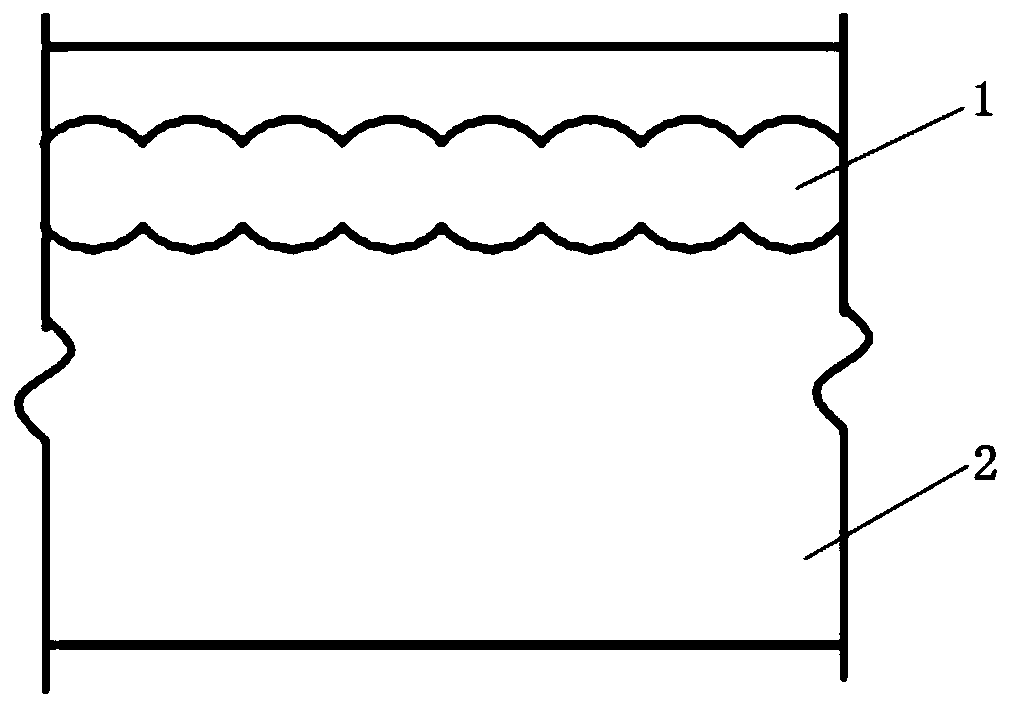

[0048] A saturated sandstone layer occlusal water-stop pile support system, including water-stop piles, support piles and prestressed anchor cables 4, the water-stop piles and support piles are arranged alternately in sequence, and the adjacent water-stop piles and support piles are connected to each other The water-stop pile is a plain concrete pile, and the support pile is a reinforced concrete pile. The upper end of the water-stop pile and the support pile is provided with a crown beam, and the crown beam is connected and fixed through the steel cage exposed at the upper end of the support pile. The stress anchor cable 4 penetrates from the outside of the support pile and passes through the outside of the grouting and occlusal water stop pile 3, that is, the rock and soil outside the foundation pit are stabilized, the rock and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com