Construction method of marine self-floating type steel soleplate single-wall suspension box cofferdam and single-wall suspension box cofferdam

A construction method and technology for steel base plates, which are applied in infrastructure engineering, bridge parts, and erection/assembly of bridges, etc., can solve the problems of unreusable cofferdam base plates, speed up construction progress, increase cost input, etc., so as to reduce assembly joints. and assembly workload, reduce installation difficulty, and reduce the effect of assembly seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in further detail below in conjunction with embodiment.

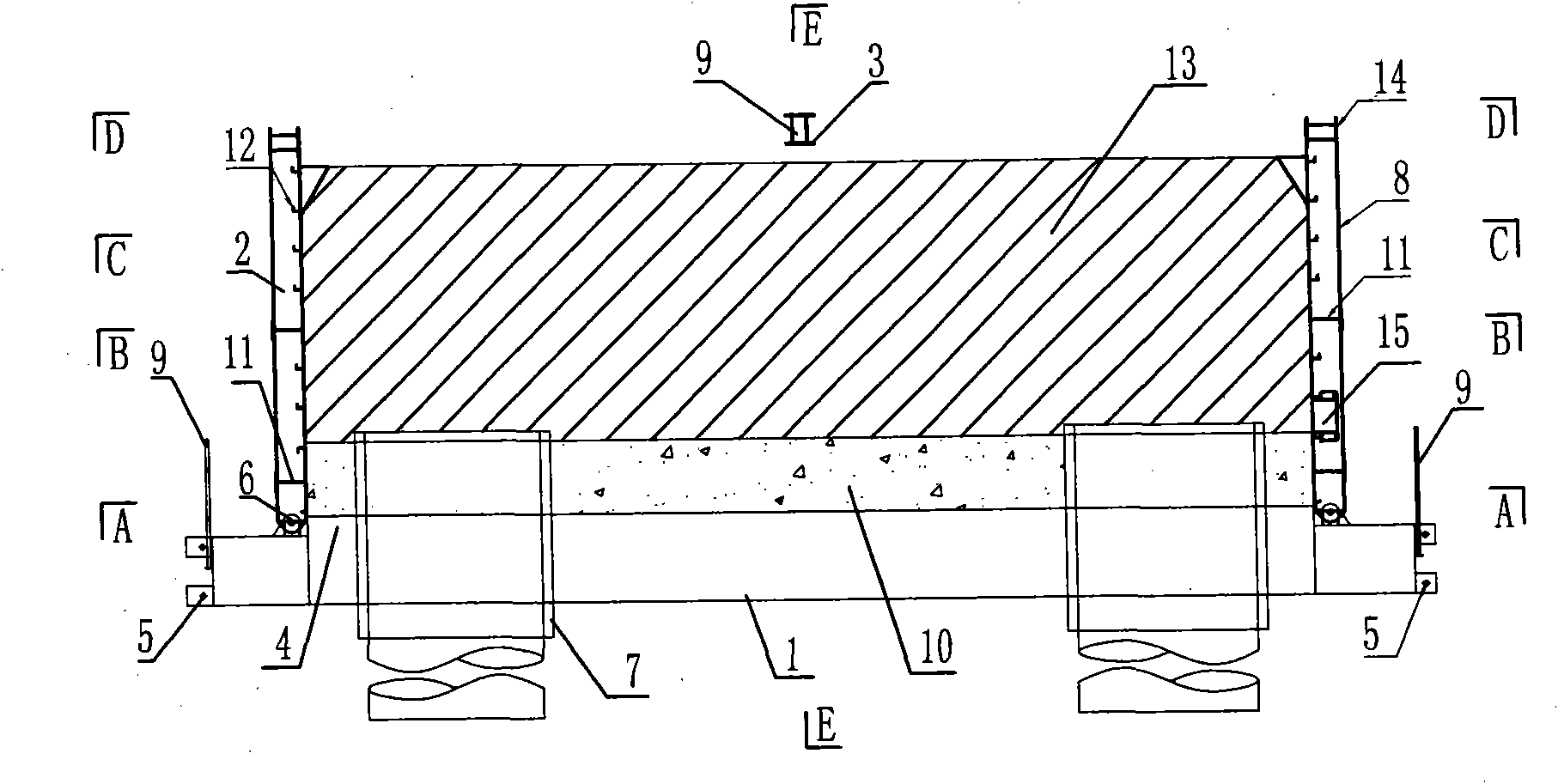

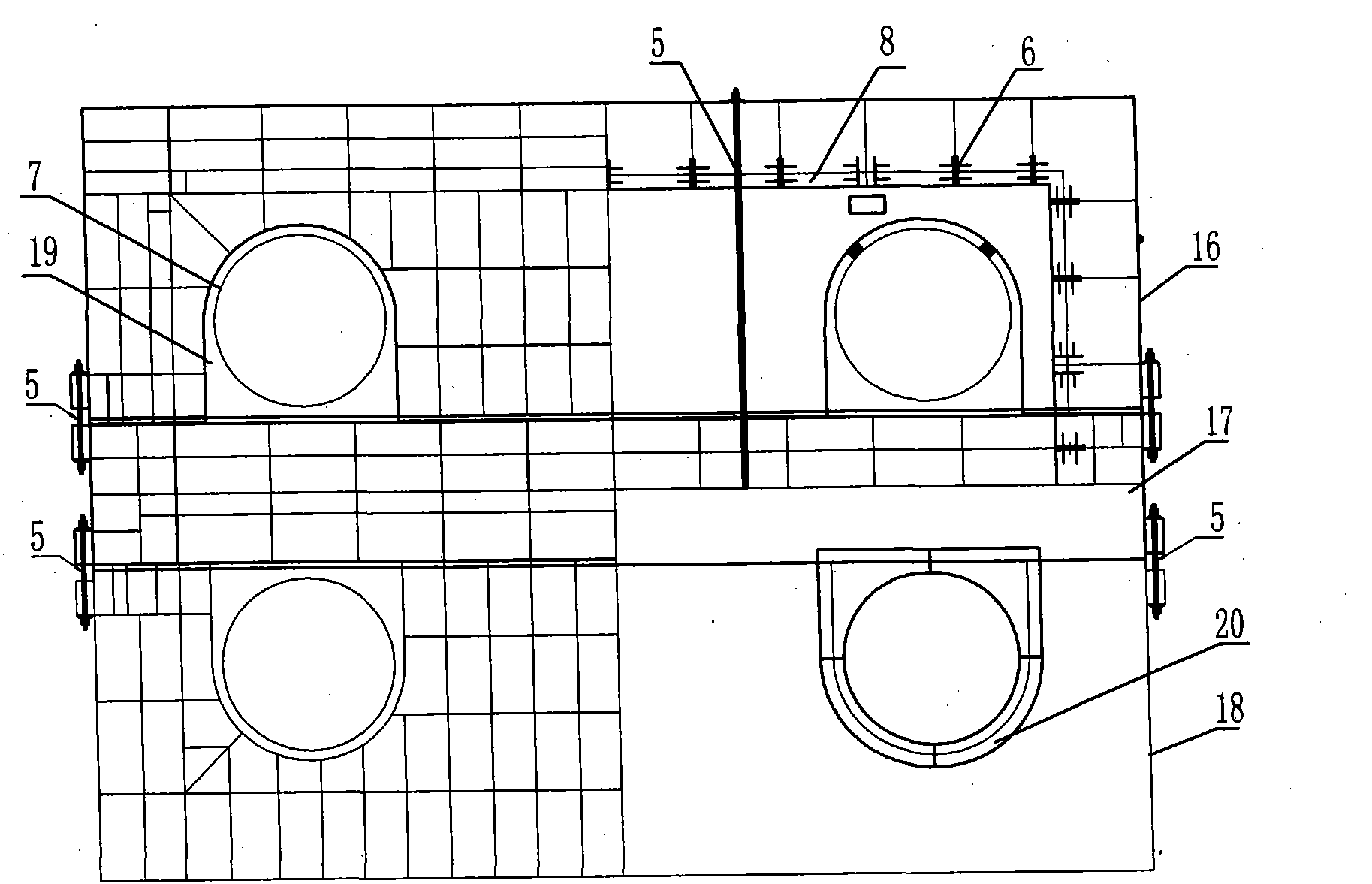

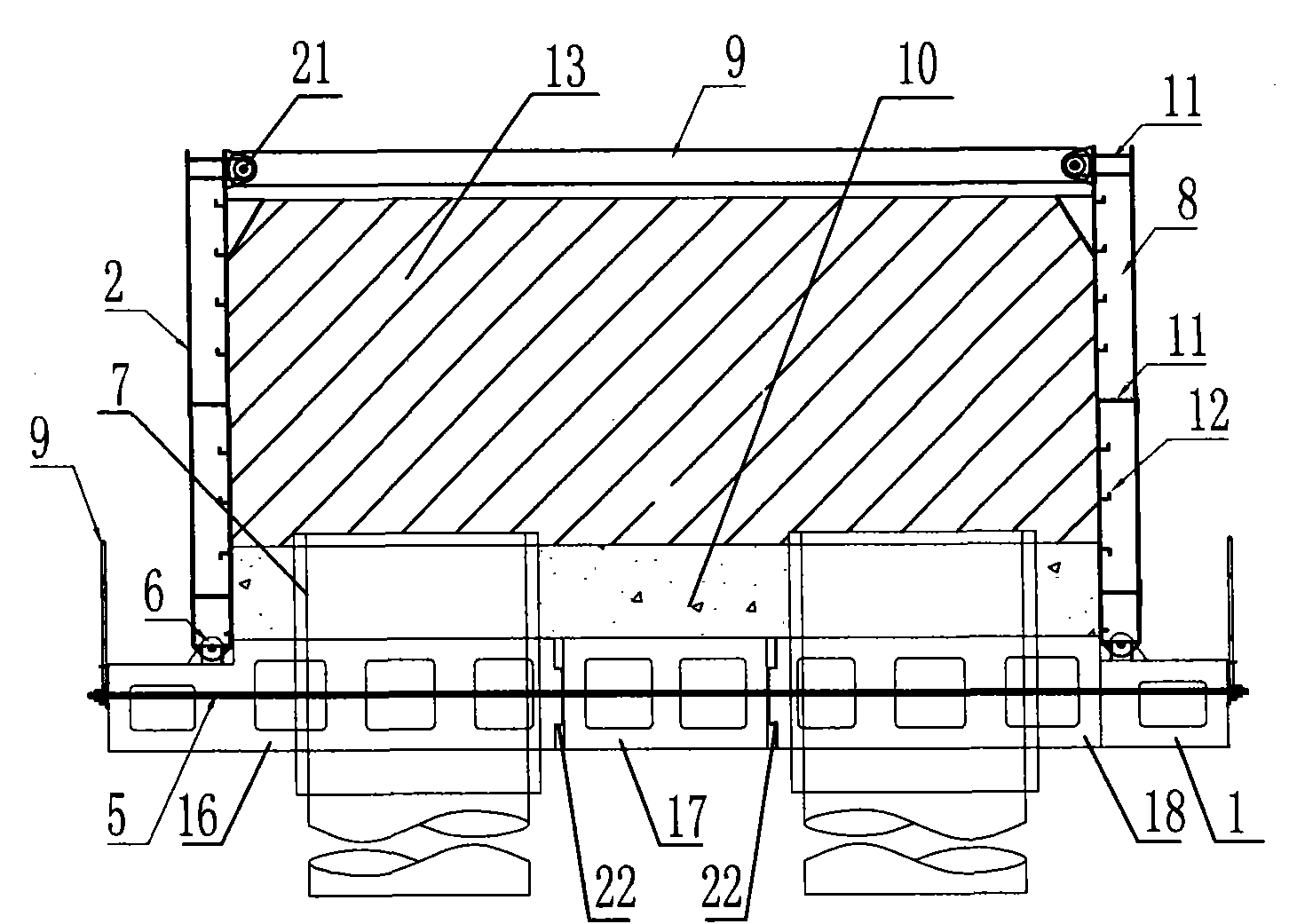

[0042] A construction method for offshore self-floating steel floor 1 single-wall hanging box cofferdam:

[0043] A. Install the bottom plate of the cofferdam, hang the pole beam and lower the guide device 4: After the bored pile construction is completed, remove the drilling platform, and first measure the installation elevation points of the four distribution beams 25 on the steel casing 7 with a level , then draw the elevation line on the steel casing 7 with a steel ruler, cut the steel casing 7, install the distribution beam 25 and the upper floor guide 24 on the top of the steel casing 7, and weld the cow on the steel casing 7 at the design elevation. Leg 27, install the lower layer lowering guide 26 on the corbel 27 on the outside of the steel casing 7, install the bottom plate hanging shoulder beam 30 on the corbel 27 inside the steel casing 7, and install the hanging boo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com