Integral hoisting system for superaltitude overlong jumbo beam by truss method and construction method thereof

A technology of overall lifting and construction methods, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the inability to realize three-dimensional operations and the safety hazards of falling objects from high altitudes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

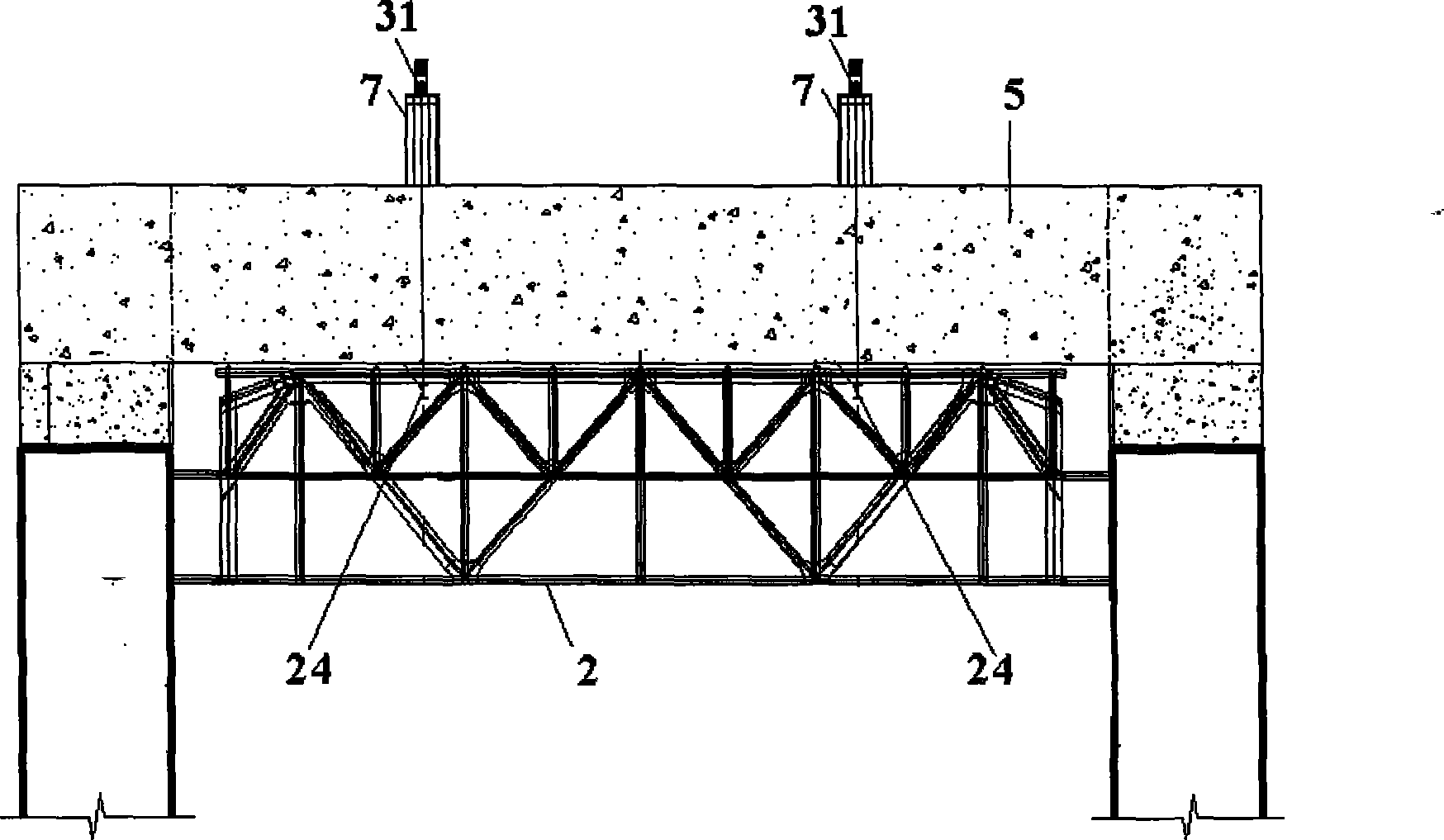

[0021] For example, the upper beam of a bridge tower is a prestressed reinforced concrete cavity beam structure spanning the left and right tower columns. The beam is 9 meters high, 43.8 meters long and 8 meters wide. It is a super-high-altitude super-long giant beam structure,

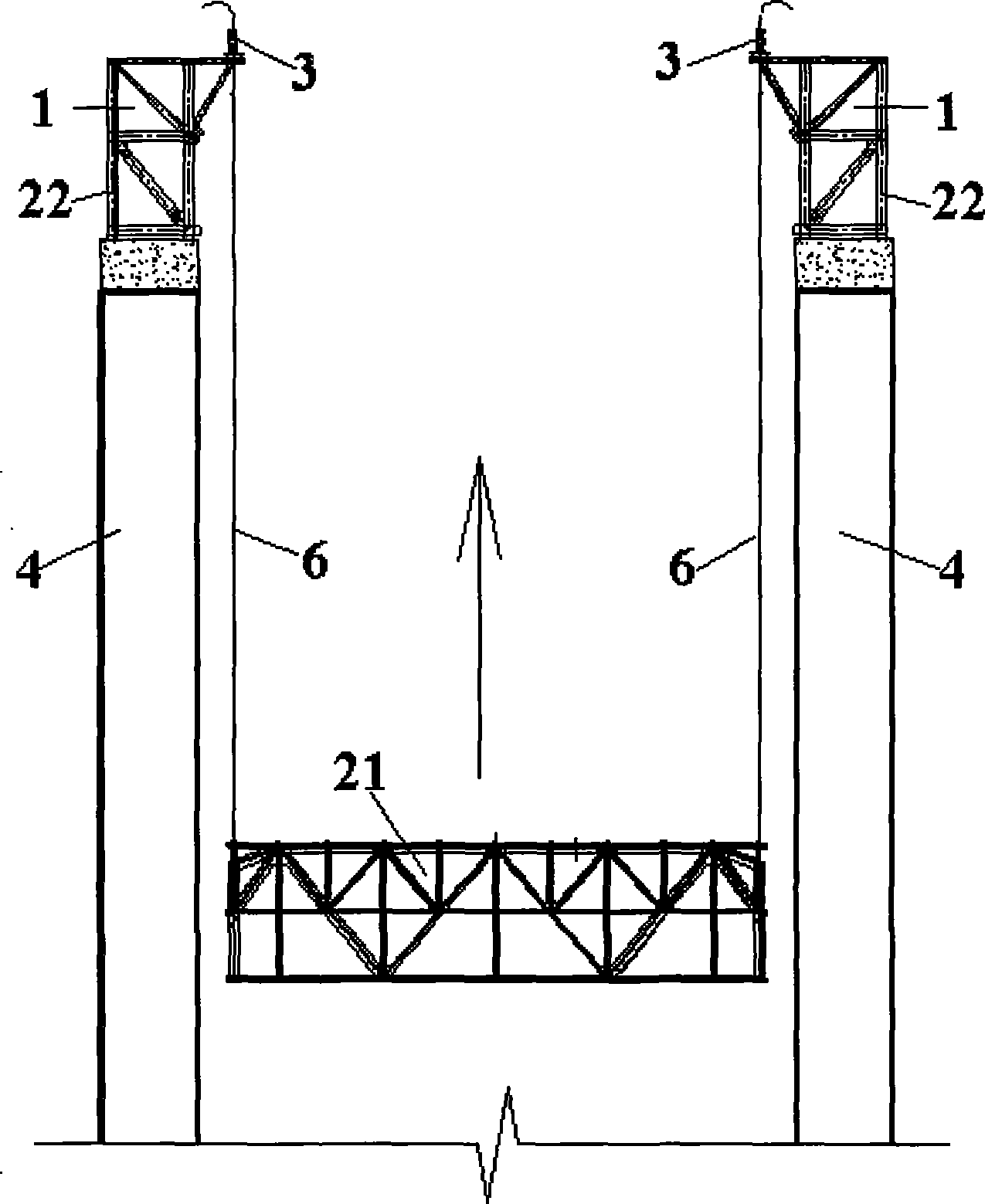

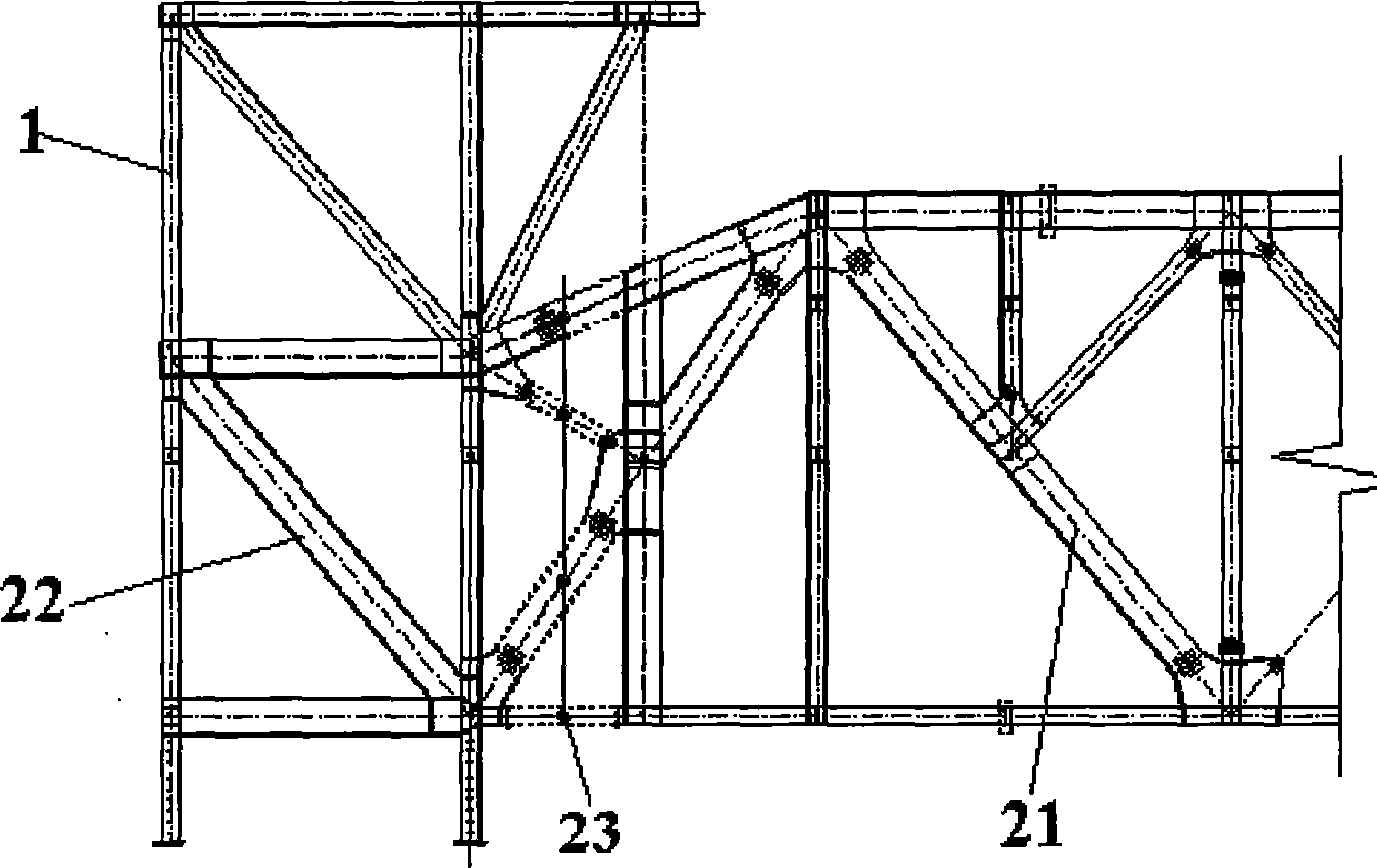

[0022] Such as figure 1 As shown, the overall lifting system of the super-high-altitude super-long giant beam truss method of the present invention includes a lifting bracket 1, a formwork truss 2 and a lifting power system 3, and the formwork truss 2 includes a main body truss 21 and an end fixed truss 22. The end fixed trusses 22 are fixed on the vertical structures 4 on both sides of the giant beam 5, the lifting bracket 1 is fixedly arranged on the fixed trusses 22 at both ends, the lifting power system 3 is fixed on the lifting bracket 1, and the lifting power The system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com