Brake system and method for operating a brake system

A braking system and master brake cylinder technology, applied in electric braking systems, brakes, electric vehicles, etc., can solve the problems of expensive and expensive electronic devices, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

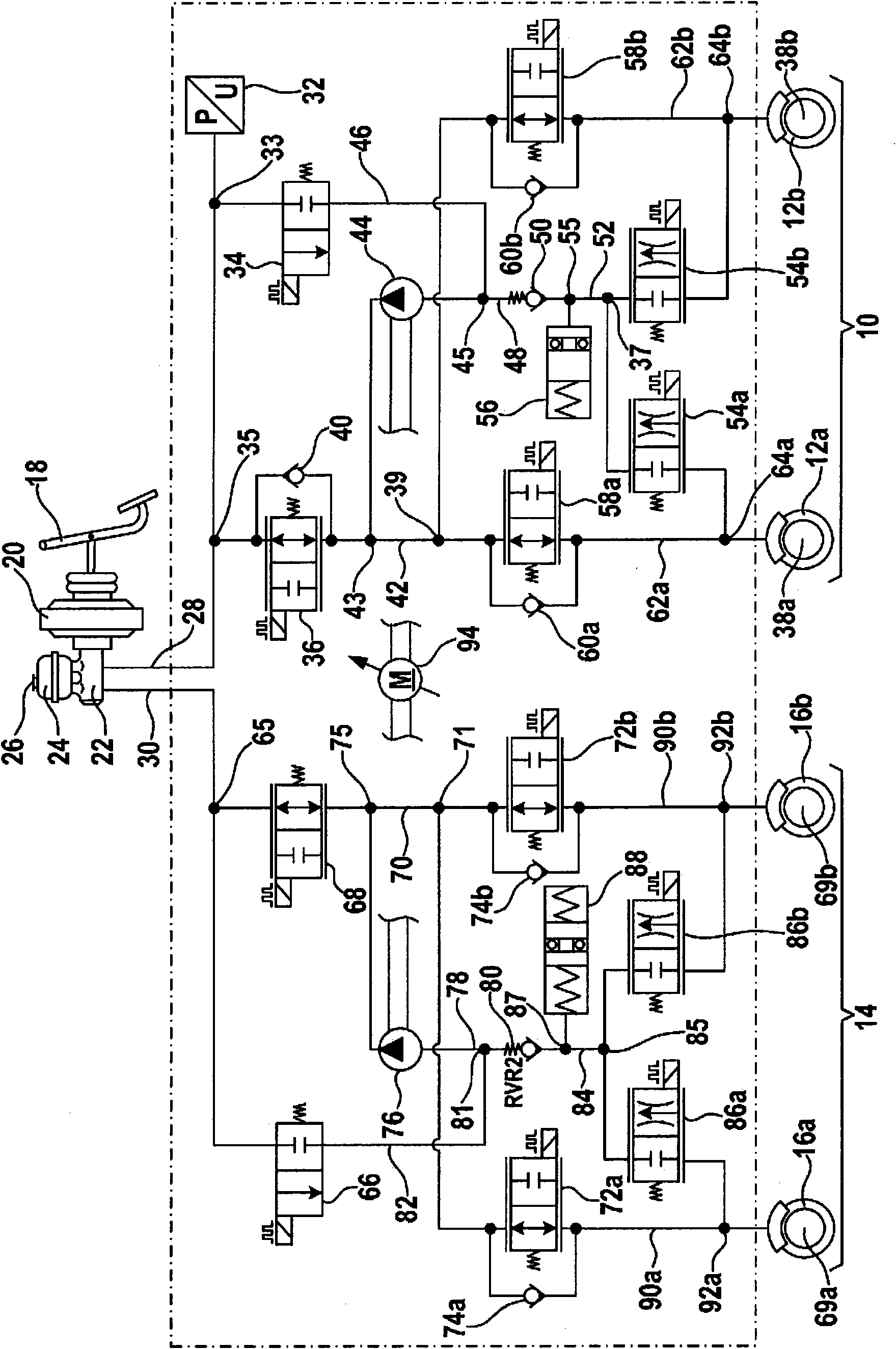

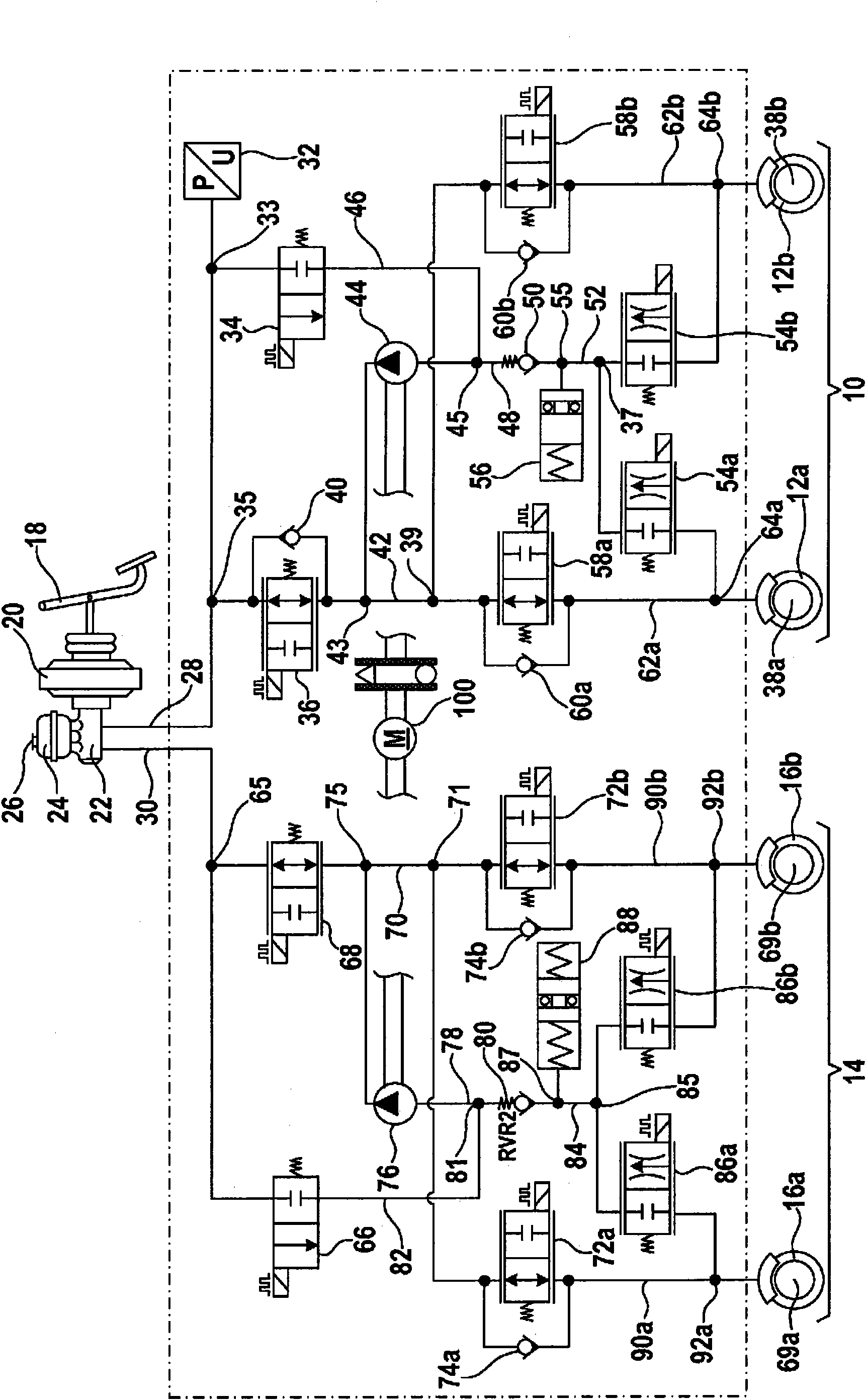

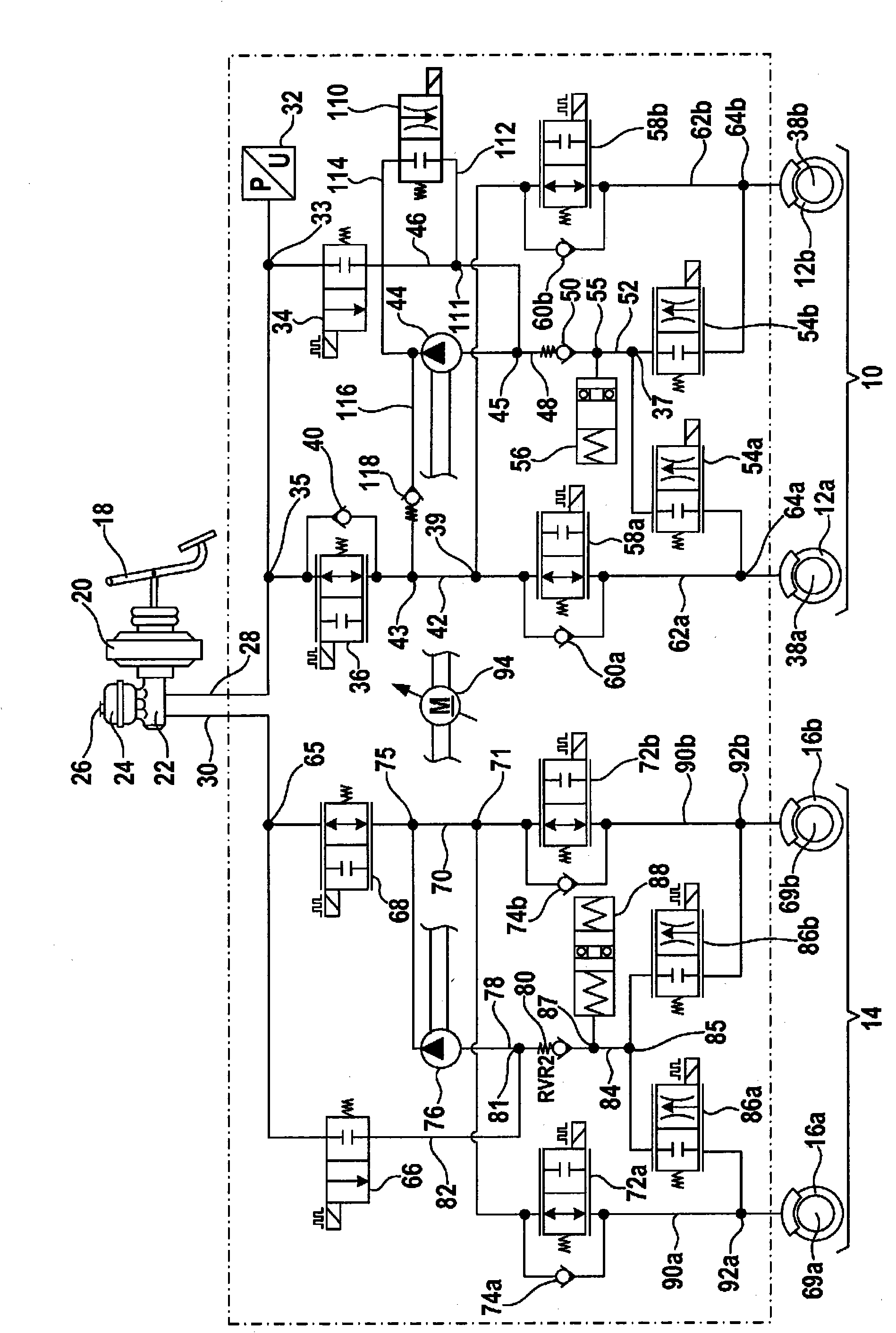

[0029] figure 1 A circuit diagram of a first embodiment of the brake system is shown.

[0030] exist figure 1The brake system shown in is designed as a dual-piston system by way of example. The braking system comprises a front brake circuit 10 for braking the front wheels 12a and 12b and a rear brake circuit 14 for braking the rear wheels 16a and 16b. However, the example shown is not limited to this distribution of the wheels 12a, 12b, 16a and 16b. Of course, this example can also be applied to an embodiment in which the wheels 12a and 12b are the rear wheels of the vehicle and the wheels 16a and 16b are the front wheels of the vehicle. The wheels 12a and 12b and the wheels 16a and 16b can also be two pairs of wheels arranged on two different sides of the vehicle or arranged diagonally on the vehicle.

[0031] It is hereby clearly stated that the figure 1 The braking system shown in is not limited to a fixed number of four wheels 12a, 12b, 16a and 16b. Alternatively, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com