Carbon ceramic brake shoe for urban rail vehicle and manufacturing method thereof

A technology for urban rail and urban rail vehicles, applied in the field of carbon fiber reinforced ceramic-based friction materials, can solve the problems of unstable braking performance, poor thermal stability, low braking power, etc., to ensure reliability and safety, friction The effect of stable coefficient and smooth braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Carbon-ceramic brake shoes for urban rail vehicles, with continuous carbon fibers as reinforcing fibers, pyrolytic carbon and SiC ceramic materials as matrix materials, pyrolytic carbon matrix prepared by chemical vapor infiltration method, ceramics prepared by directional molten silicon infiltration method matrix.

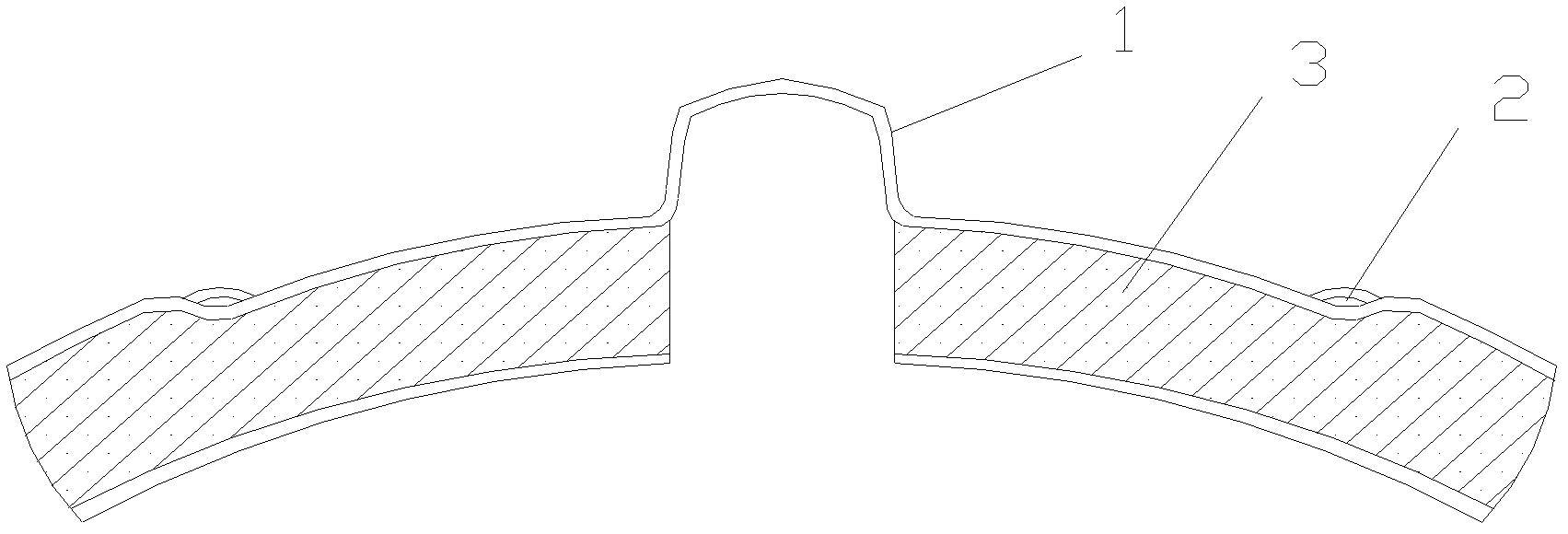

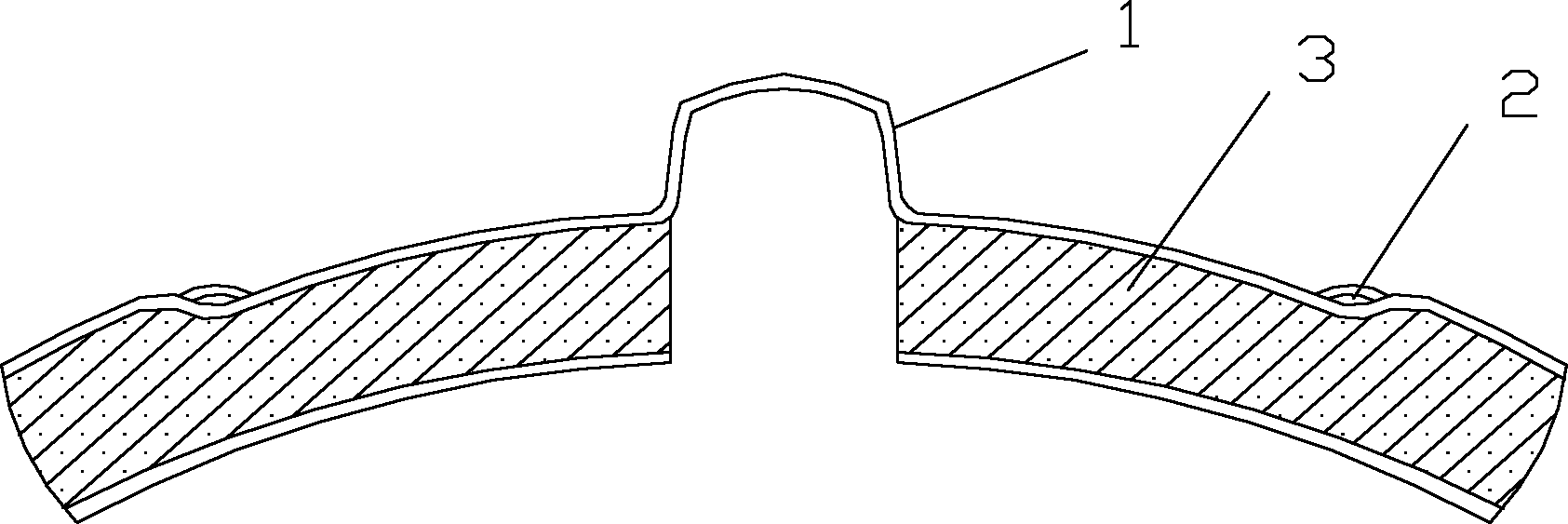

[0046] see figure 1 , the method for manufacturing carbon ceramic brake shoes for urban rail vehicles is as follows:

[0047] (1) Made of PAN-type T700 (12K) carbon fiber produced by Toray, Japan, with a density of 0.46g / cm 3 carbon fiber prefabricated body;

[0048] (2) The carbon fiber prefabricated body is subjected to a high-temperature heat treatment at 1600°C for 20 hours, with slight positive pressure and argon inert gas protection;

[0049] (3) Natural gas is used as the carbon source gas, hydrogen is used as the dilution gas, and the volume ratio of natural gas and hydrogen is 1:3. The carbon matrix is deposited at 1000°C by chemical vapor inf...

Embodiment 2

[0057] Carbon-ceramic brake shoes for urban rail vehicles, with continuous carbon fibers as reinforcing fibers, pyrolytic carbon and SiC ceramic materials as matrix materials, pyrolytic carbon matrix prepared by chemical vapor infiltration method, ceramics prepared by directional molten silicon infiltration method matrix.

[0058] The method for making urban rail vehicle carbon ceramic brake shoe is as follows:

[0059] (1) Made of PAN-type T700 (12K) carbon fiber produced by Toray, Japan, with a density of 0.55g / cm 3 carbon fiber prefabricated body;

[0060] (2) Under an argon protective atmosphere, the preform is subjected to a high-temperature heat treatment at 1600°C for 18 hours, with slight positive pressure and argon inert gas protection;

[0061] (3) Propylene is used as the carbon source gas, hydrogen is used as the dilution gas, and the volume ratio of propylene to hydrogen is 1:2. The pyrolytic carbon matrix is deposited on the preform at 1100 ° C by chemical va...

Embodiment 3

[0068] Carbon-ceramic brake shoes for urban rail vehicles, with continuous carbon fibers as reinforcing fibers, pyrolytic carbon and SiC ceramic materials as matrix materials, pyrolytic carbon matrix prepared by chemical vapor infiltration method, ceramics prepared by directional molten silicon infiltration method matrix.

[0069] The method for making urban rail vehicle carbon ceramic brake shoe is as follows:

[0070] (1), Acupuncture carbon fiber integral felt:

[0071] The single-layer 0° non-weft cloth, tire mesh, 90° non-weft cloth, and tire mesh are superimposed in sequence, and then the superimposed non-weft cloth and mesh tire are repeatedly needled with barbs to make a carbon fiber whole Felt having a density of 0.40 g / cm 3 ;

[0072] (2) The carbon fiber prefabricated body is subjected to high-temperature heat treatment at 900°C, the whole time is 8 hours, under slight positive pressure, and protected by argon inert gas;

[0073] (3) Using methane as the carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com