Constant volume bomb for diesel spraying and burning visualization experiment

A constant-volume bomb and diesel technology, which is used in internal combustion engine testing, engine testing, and machine/structural component testing. High pressure requirements are difficult and other problems to achieve the effect of reducing local stress phenomenon, light weight, and reducing experimental cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

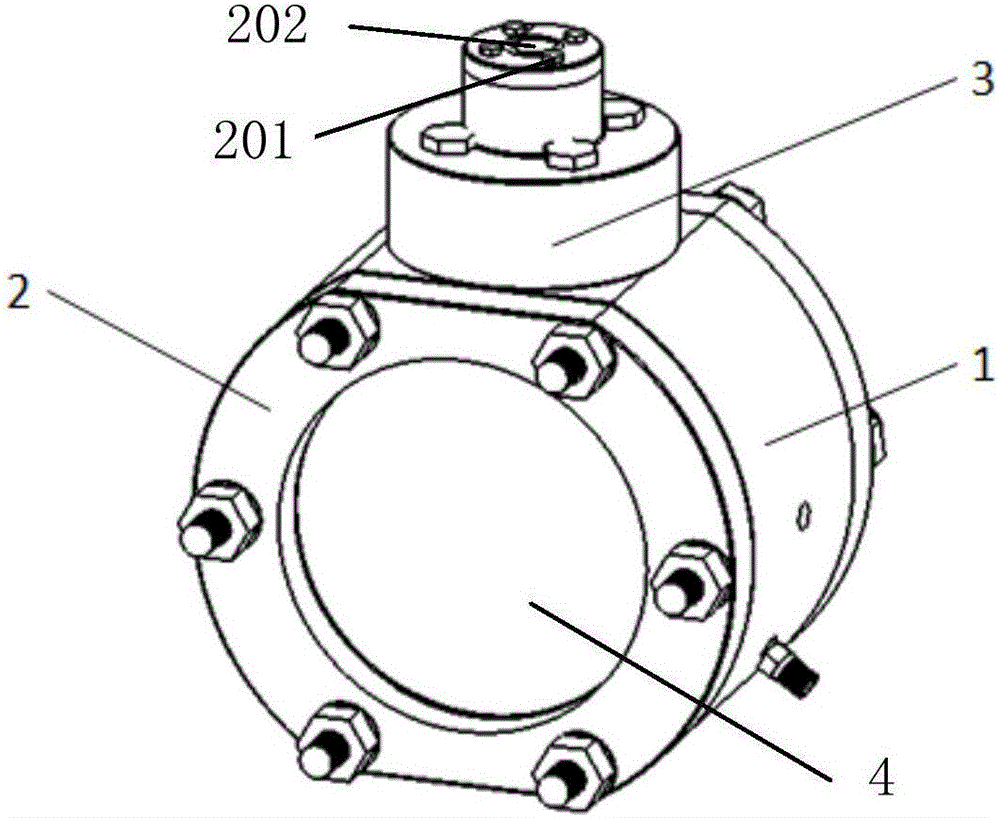

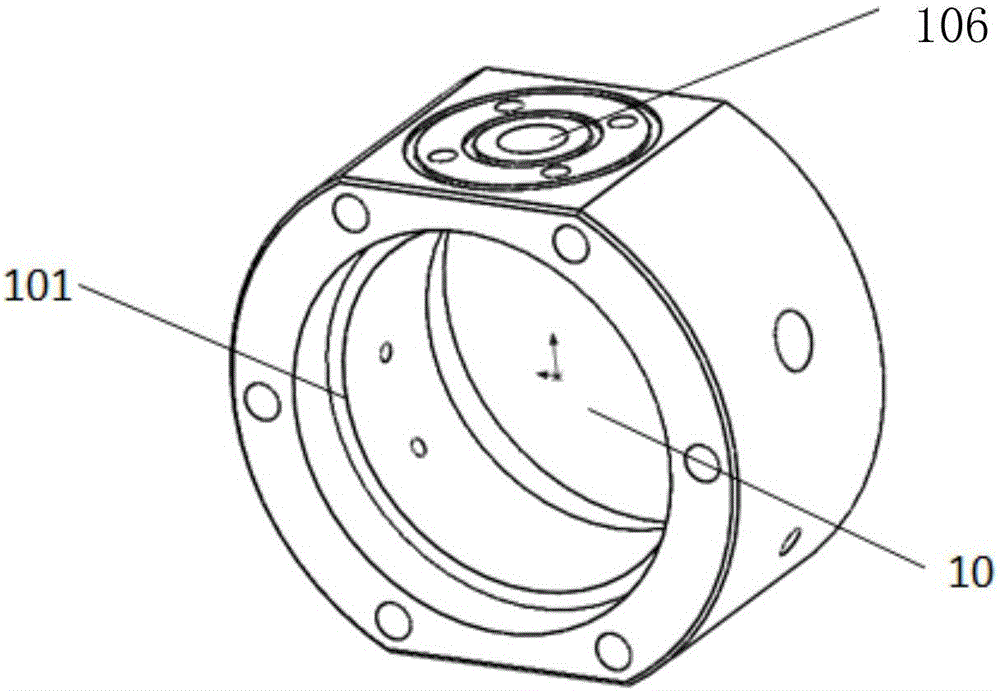

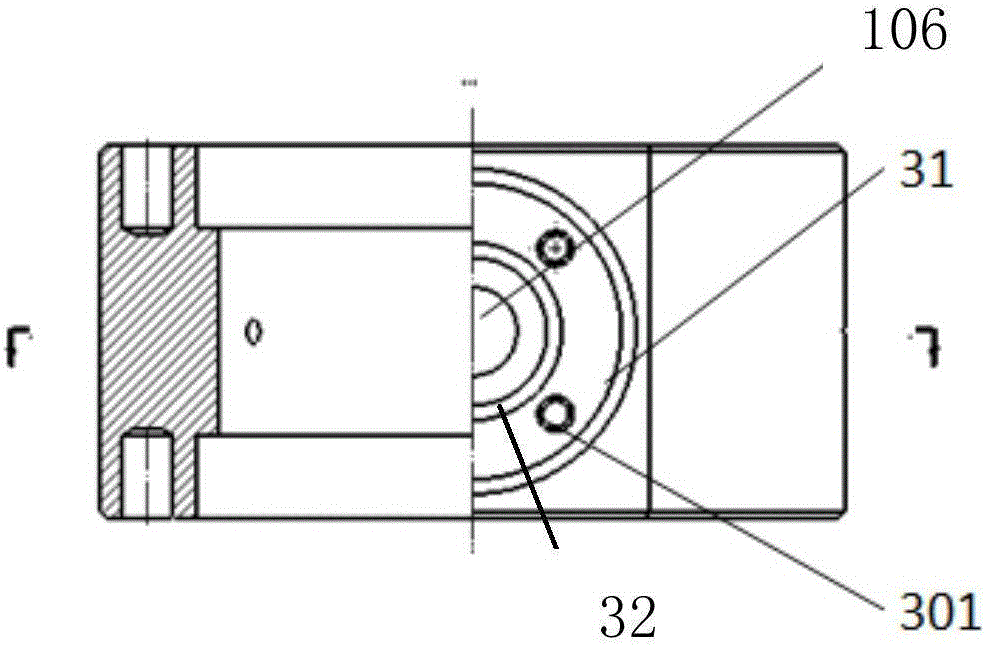

[0019] The present invention provides a constant-volume projectile for diesel spray and combustion visualization test, the schematic diagram of its appearance is as follows figure 1 As shown, it mainly includes: constant volume bomb body 1, sealing cover 2, top cover 3, and quartz glass window 4. The constant volume bullet body 1 adopts a circular cake-shaped structure, and the interior is hollow to form a visual test area 10. Windows are opened on both sides of the circular cake and annular installation grooves of the same size are processed to install the window assembly. The diameter of the installation groove is 186mm and the depth It is about 0.75 times the thickness of quartz glass, and the quartz glass 4 is fixed with a metal sealing cover 2 for sealing. The sealing end faces of the two bear the main sealing pressure; There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com