Method of producing ranadium pentoxide using vanadium containing waste catalyst

A technology of vanadium pentoxide and waste catalyst, which is applied in the direction of catalyst regeneration/reactivation, vanadium oxide, chemical instruments and methods, etc. Extended life, no maintenance costs, and reduced floor space effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

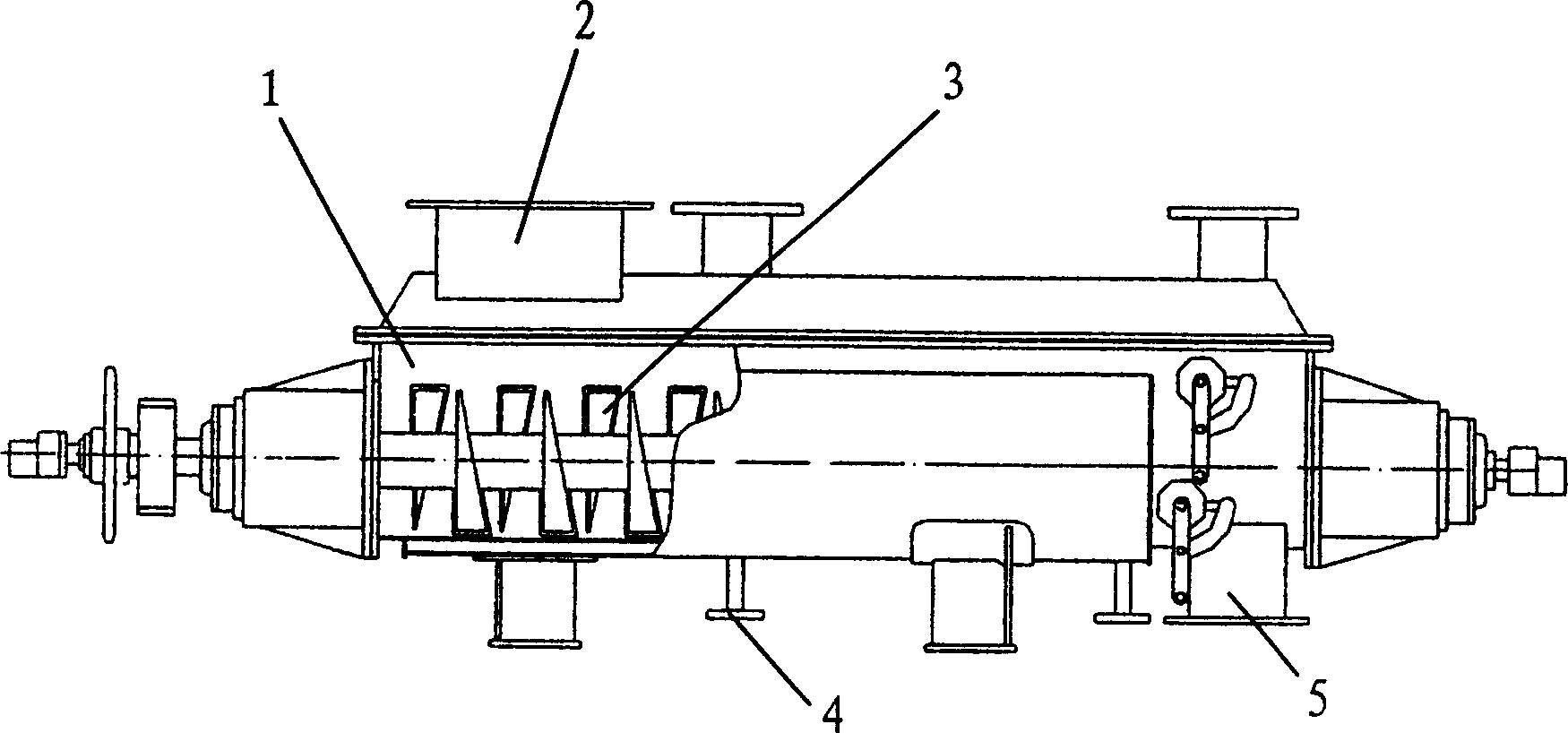

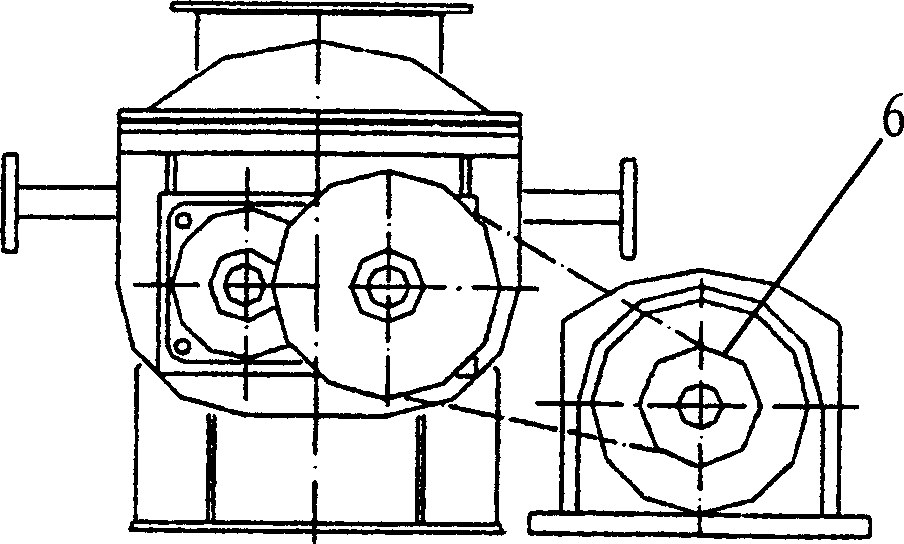

Image

Examples

Embodiment

9-9.5

97.32

[0056] 4. The calcined material is then dissolved in 2.5-3 times the weight of hot water at 80-85°C, and the leaching time is 40-60 minutes under stirring. At the same time, it is filtered through a filter to separate the solid from the liquid, and recover sodium vanadate and molybdic acid Sodium solution is the secondary leaching solution;

[0057] 5. Combine the above two leaching liquids; press 5kg / m 3 Add CaCl 2 Remove impurity phosphorus, filter and separate the leaching solution through a plate and frame filter at room temperature to form a purified leaching solution, add excess ammonium chloride to the leaching solution to make sodium vanadate precipitate ammonium metavanadate, and sodium molybdate stay in the solution and To achieve the separation of vanadium and molybdenum; put the separated ammonium metavanadate into the tablet furnace, and decompose the ammonium vanadate at 800-850°C to obtain molten V 2 o 5 , the finished product is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com