Cationic asphalt emulsifier and preparation method and application thereof

A technology of asphalt emulsifier and cation, which is applied in the field of cationic asphalt emulsifier and its preparation, can solve the problems of poor emulsion stability, difficulty in modifying asphalt, adjustment of formula, etc., and meet the requirements of different construction technologies and construction conditions, Effects with a wide range of selection and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Put lauric acid and 4-tert-butylbenzoic acid into the reactor in a molar ratio of 1:1, then add ethylenediamine with a molar ratio of 2:1 to the mixed organic acid, and simultaneously add lauric acid and 4-tert-butyl Mixed acid composed of benzoic acid and ethylenediamine total weight 5% xylene solvent and 1% stannous oxide catalyst, stirred and heated up to 140 ° C, reflux reaction for 9 hours, to obtain the intermediate, remove the solvent therein, and epoxy Chloropropane reacts with the intermediate after removing the solvent at a molar ratio of 0.5:1, controls the reaction temperature at 75±5°C, and reacts for 0.5 hours to prepare the main agent of the cationic asphalt emulsifier, and then compound with 1% of the weight of the main agent Mix OP-10 and 1% aluminum sulfate at 45°C for 1 hour to obtain cationic asphalt emulsifier, which is reserved for emulsification test.

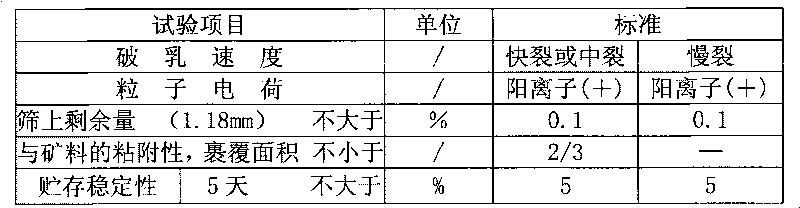

[0030] Prepare the asphalt emulsifier obtained above into a 4% by weight emulsifier aqueous sol...

Embodiment 2

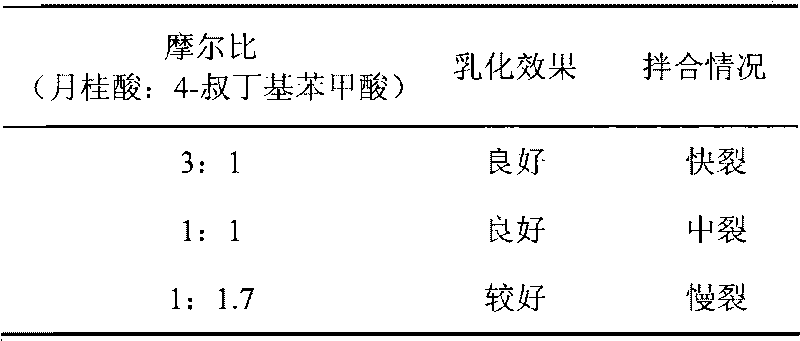

[0032] Using the same method and process conditions as in Example 1, keeping the molar ratio of mixed acid and amine at 1:1, investigate the 4-tert-butylbenzoic acid with relatively large steric hindrance effect and lauric acid with relatively small steric hindrance effect Under different proportioning conditions, the obtained emulsifier prepared asphalt emulsion emulsification and mixing effect with aggregate, the results are as follows:

[0033]

Embodiment 3

[0035] Put oleic acid and syringic acid into the reactor in a molar ratio of 1:1, and then add a mixed amine composed of triethylenetetramine and 1,2-propylenediamine with a molar ratio of 1:1 to the mixed organic acid. The molar ratio of triethylenetetramine and 1,2-propylenediamine is 1:1, and at the same time, add 8% toluene solvent and 3% azobisisobutyronitrile catalyst of the total weight of mixed acid and mixed amine, stir and heat up to 120 ℃, reflux reaction for 10 hours to obtain an intermediate, remove the solvent therein, react the intermediate with the molar ratio of 1:1 between methyl chloride and the removed solvent, control the reaction temperature at 70±5°C, and the reaction time for 2 hours to obtain The main agent of cationic asphalt emulsifier is compounded with 2.5% AEO3 and 2.5% calcium chloride by weight of the main agent, and stirred and blended at 60°C for 1 hour to obtain cationic asphalt emulsifier, which is reserved for emulsification test.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com