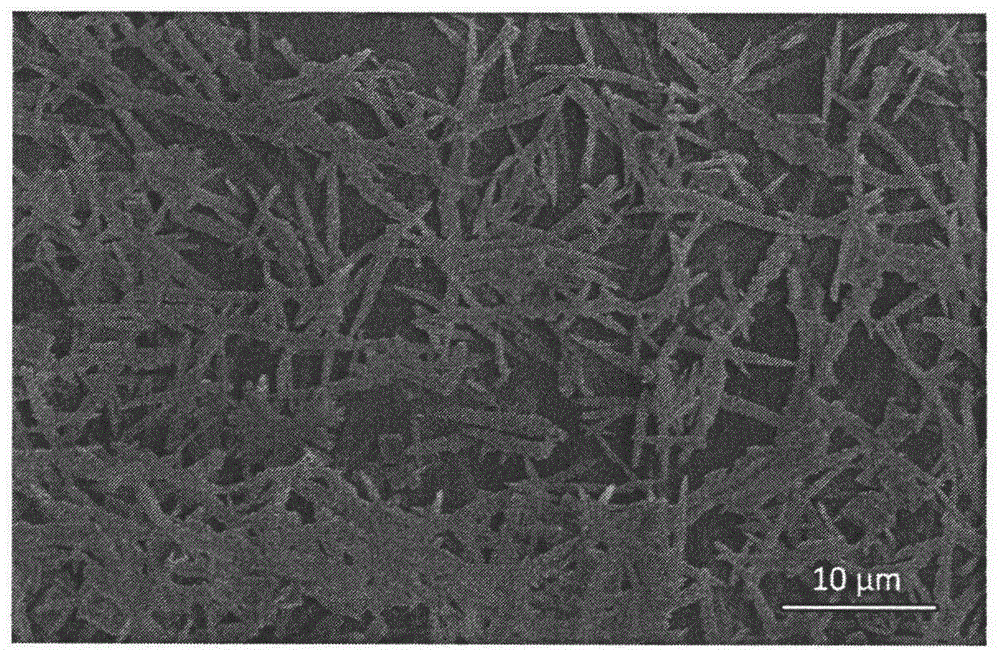

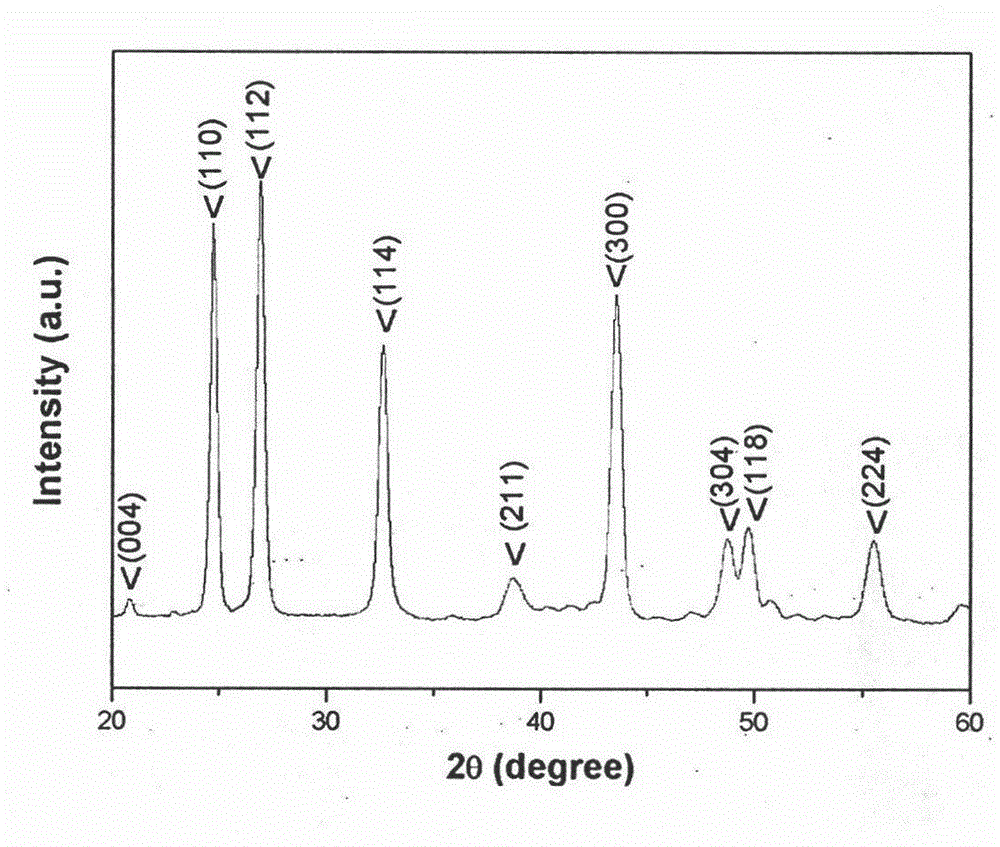

Method for preparing micron-grade acicular vaterite calcium carbonate

A technology of vaterite and calcium carbonate, applied in the direction of calcium carbonate/strontium/barium, etc., to achieve the effect of simple process, safe operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] ①Take 1.0g of dodecyltrimethylammonium bromide (DTAB), add 25ml of distilled water, place at 20°C, and electromagnetically stir for 3 minutes to obtain a clear and transparent liquid A.

[0019] ②Weigh 11.2g calcium chloride (CaCl 2 ), dissolved in 80ml of distilled water, placed in an environment of 25°C, and electromagnetically stirred for 3 minutes to obtain a clear and transparent liquid B.

[0020] ③Weigh 10.6g sodium carbonate (Na 2 CO 3 ), dissolved in 80ml of distilled water, placed in an environment of 25°C, and electromagnetically stirred for 3min. A clear and transparent liquid C was obtained.

[0021] ④Measure 6ml of A and mix with 6ml of B and C solutions to obtain transparent and clear liquids D and E, and place D and E liquids at 25°C for 10 minutes with electromagnetic stirring.

[0022] ⑤ Slowly add liquid D dropwise (2d / s) into liquid E, and place the mixed liquid F at 25°C, and stir it electromagnetically for 30 minutes.

[0023] ⑥ Centrifuge the...

Embodiment 2

[0025] ①Take 1.0g of dodecyltrimethylammonium bromide (DTAB), add 25ml of distilled water, place at 20°C, and electromagnetically stir for 3 minutes to obtain a clear and transparent liquid A.

[0026] ②Weigh 11.2g calcium chloride (CaCl 2 ), dissolved in 80ml of distilled water, placed in an environment of 25°C, and electromagnetically stirred for 3 minutes to obtain a clear and transparent liquid B.

[0027] ③Weigh 10.6g sodium carbonate (Na 2 CO 3 ), dissolved in 80ml of distilled water, placed in an environment of 25°C, and electromagnetically stirred for 3min. A clear and transparent liquid C was obtained.

[0028] ④Measure 6ml of A and mix with 6ml of B and C solutions to obtain transparent and clear liquids D and E, and place D and E liquids at 25°C for 10 minutes with electromagnetic stirring.

[0029] ⑤ Slowly add liquid D dropwise (2d / s) into liquid E, and place the mixed liquid F at 25°C, and stir it electromagnetically for 5 minutes.

[0030] ⑥ Centrifuge the ...

Embodiment 3

[0032] ①Take 1.0g of dodecyltrimethylammonium bromide (DTAB), add 25ml of distilled water, place at 20°C, and electromagnetically stir for 3 minutes to obtain a clear and transparent liquid A.

[0033] ②Weigh 11.2g calcium chloride (CaCl 2 ), dissolved in 80ml of distilled water, placed in an environment of 25°C, and electromagnetically stirred for 3 minutes to obtain a clear and transparent liquid B.

[0034] ③Weigh 10.6g sodium carbonate (Na 2 CO 3 ), dissolved in 80ml of distilled water, placed in an environment of 25°C, and electromagnetically stirred for 3min. A clear and transparent liquid C was obtained.

[0035] ④Measure 6ml of A and mix with 6ml of B and C solutions to obtain transparent and clear liquids D and E, and place D and E liquids at 25°C for 10 minutes with electromagnetic stirring.

[0036] ⑤ Slowly add liquid D dropwise (2d / s) into liquid E, and place the mixed liquid F at 25°C, and stir it electromagnetically for 10 minutes.

[0037] ⑥ Centrifuge the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com