Method and device for preparing vaterite by using magnetic field

A technology of vaterite and magnetic field, which is applied in the fields of chemical instruments and methods, inorganic chemistry, calcium/strontium/barium compounds, etc. It can solve the problems of complex operation process, cumbersome process, and increased production cost, and achieve high product purity and simple process , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment is aimed at the low concentration of Na 2 CO 3 The reaction solution was subjected to the preparation of vaterite.

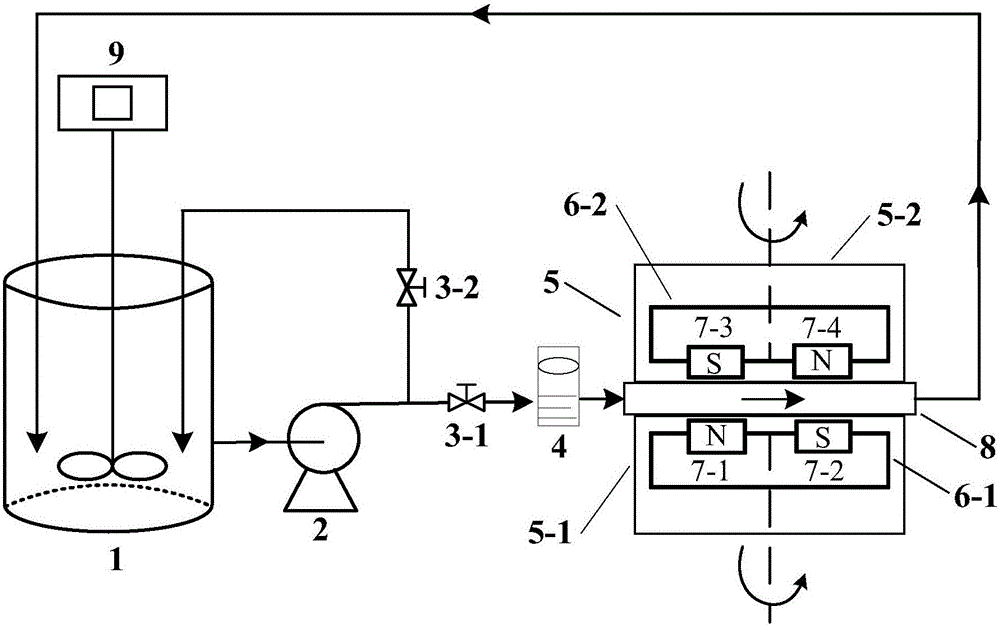

[0043] A diaphragm pump is installed at the outlet of the reactor, and a bypass flow regulating valve and a main path flow regulating valve are installed on the outlet pipeline of the diaphragm pump to adjust the flow rate of the reaction solution passing through the magnetizer.

[0044] Install a flow meter on the outlet pipeline of the main road flow regulating valve, and install a magnetizer at the outlet of the flow meter. The interior of the magnetizer is composed of a lower magnetizer, an upper magnetizer and a magnetization channel. Both the upper and lower magnetizers are composed of a turntable and a pair of permanent magnets, and each pair of permanent magnets is embedded on the turntable. On the lower magnetizer turntable, the N pole of the permanent magnet faces upward, and the S pole of the other permanent magnet faces upwar...

Embodiment 2

[0049] This embodiment is aimed at the NaHCO of low concentration 3 Reaction solution, change the magnetic treatment conditions, and carry out the preparation of vaterite.

[0050] A diaphragm pump is installed at the outlet of the reactor, and a bypass flow regulating valve and a main path flow regulating valve are installed on the outlet pipeline of the diaphragm pump to adjust the flow rate of the reaction solution passing through the magnetizer.

[0051] Install a flow meter on the outlet pipeline of the main road flow regulating valve, and install a magnetizer at the outlet of the flow meter. The interior of the magnetizer is composed of a lower magnetizer, an upper magnetizer and a magnetization channel. Both the upper and lower magnetizers are composed of a turntable and a pair of permanent magnets, and each pair of permanent magnets is embedded on the turntable. On the lower magnetizer turntable, the N pole of the permanent magnet faces upward, and the S pole of the o...

Embodiment 3

[0056] This embodiment is aimed at high concentrations of Na 2 CO 3 The reaction solution was used to prepare vaterite.

[0057] A diaphragm pump is installed at the outlet of the reactor, and a bypass flow regulating valve and a main path flow regulating valve are installed on the outlet pipeline of the diaphragm pump to adjust the flow rate of the reaction solution passing through the magnetizer.

[0058] Install a flow meter on the outlet pipeline of the main road flow regulating valve, and install a magnetizer at the outlet of the flow meter. The interior of the magnetizer is composed of a lower magnetizer, an upper magnetizer and a magnetization channel. Both the upper and lower magnetizers are composed of a turntable and a pair of permanent magnets, and each pair of permanent magnets is embedded on the turntable. On the lower magnetizer turntable, the N pole of the permanent magnet faces upward, and the S pole of the other permanent magnet faces upward. One permanent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com