Method for preparing high-purity metastable vaterite calcium carbonate from gypsum

A calcium carbonate and metastable state technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of increasing the synthesis cost of aragonite calcium carbonate, the complex synthesis process of organic crystallization agents, and increasing the difficulty of experiments, etc., to achieve easy industrialization Production, crystal form high purity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

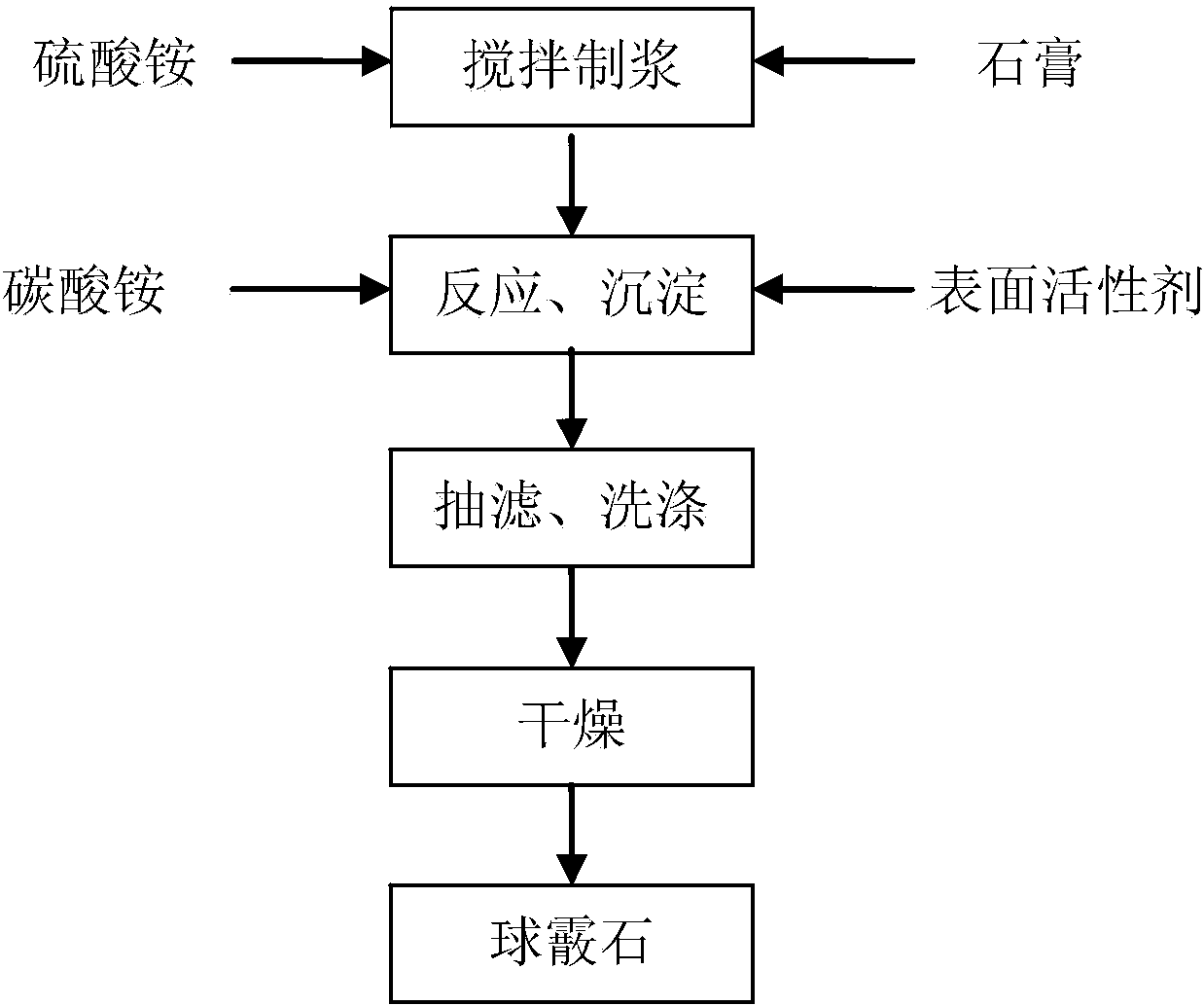

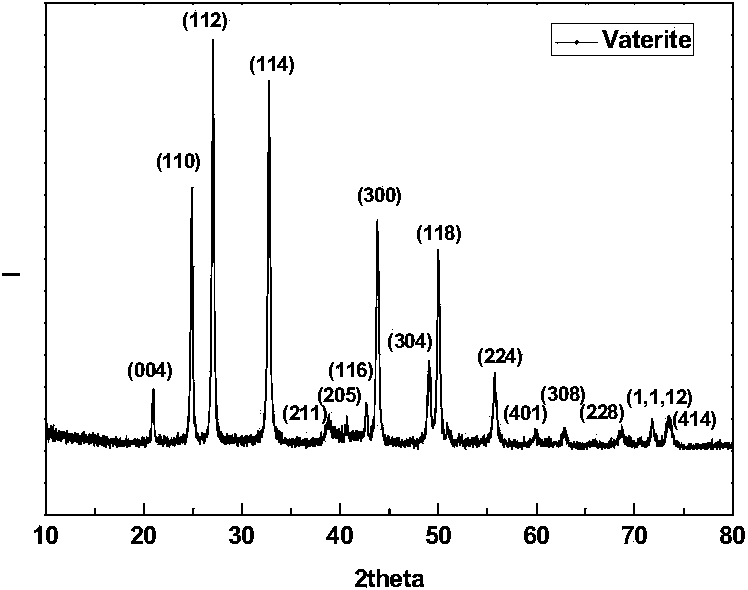

[0029] Please see attached Figure 1-3 , add 3mol / 1 ammonium sulfate solution into the reactor, keep the temperature at 25°C, add gypsum into the reactor, and start the stirring speed at 1.0m.s -1 , Slurry for half an hour; Add 3mol / 1 ammonium carbonate solution to the slurry, the material ratio of ammonium carbonate and gypsum added is 1.1; Add sodium stearate with 2.5% gypsum mass to the slurry, and react at constant temperature for 2h. After the reaction, filter with suction, wash the filter cake 5 times with deionized water, and dry it in an oven at 80° C. for 12 hours.

Embodiment 2

[0031] Add 2mol / 1 ammonium sulfate solution into the reactor, keep the temperature at 45°C, add gypsum into the reactor, and start the stirring speed at 0.7m.s -1 , pulping for half an hour; add 2mol / 1 ammonium carbonate solution to the slurry, the material ratio of ammonium carbonate and gypsum added is 1.05; constant temperature reaction for 2h. After the reaction, filter with suction, wash the filter cake 5 times with deionized water, and dry it in an oven at 80° C. for 12 hours.

Embodiment 3

[0033] Add 2mol / 1 ammonium sulfate solution into the reactor, keep the temperature at 55°C, add gypsum into the reactor, and start the stirring speed at 1.0m.s -1 , pulping for half an hour; add 2mol / 1 ammonium carbonate solution to the slurry, the material ratio of ammonium carbonate and gypsum added is 1.1; add hexyl orthosilicate with 3% gypsum mass to the slurry, and react at constant temperature for 2h . After the reaction, filter with suction, wash the filter cake 5 times with deionized water, and dry it in an oven at 80° C. for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com