Content-controllable mixed crystal form nano calcium carbonate synthesis method

A technology of nano-calcium carbonate and a synthesis method, which is applied in the field of preparation of nano-calcium carbonate materials, can solve the problems that the content of calcium carbonate crystal forms cannot be regulated, and cannot prepare nano-materials mixed with various calcium carbonate crystal forms, etc. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

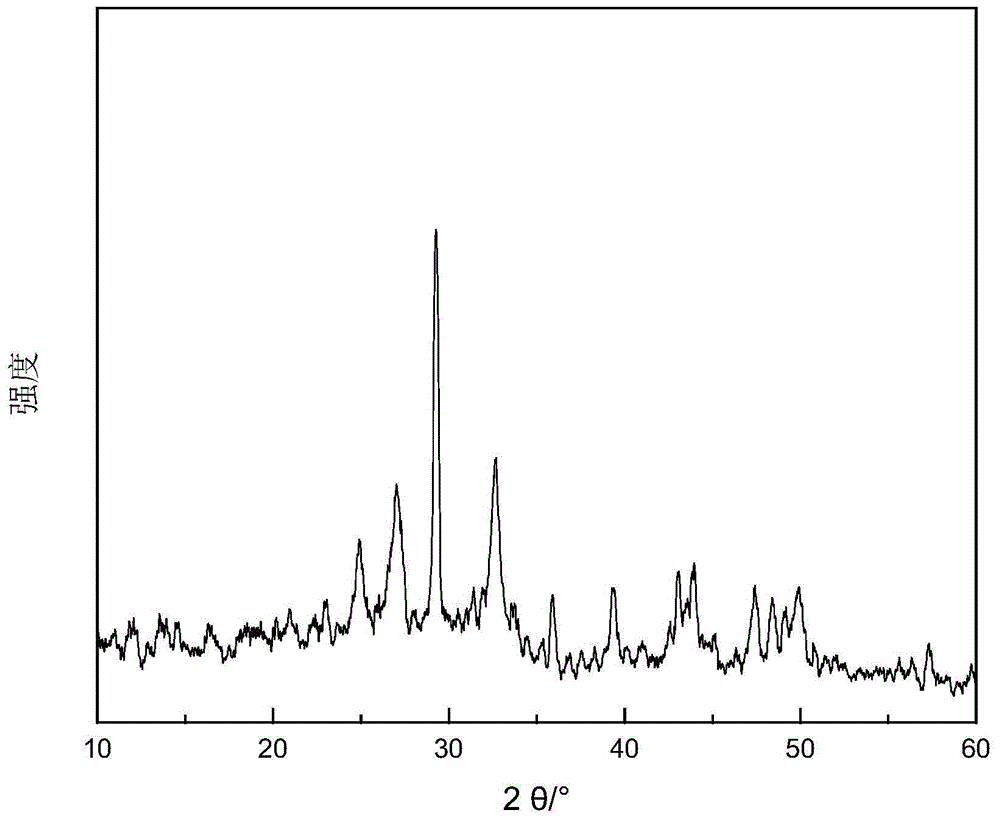

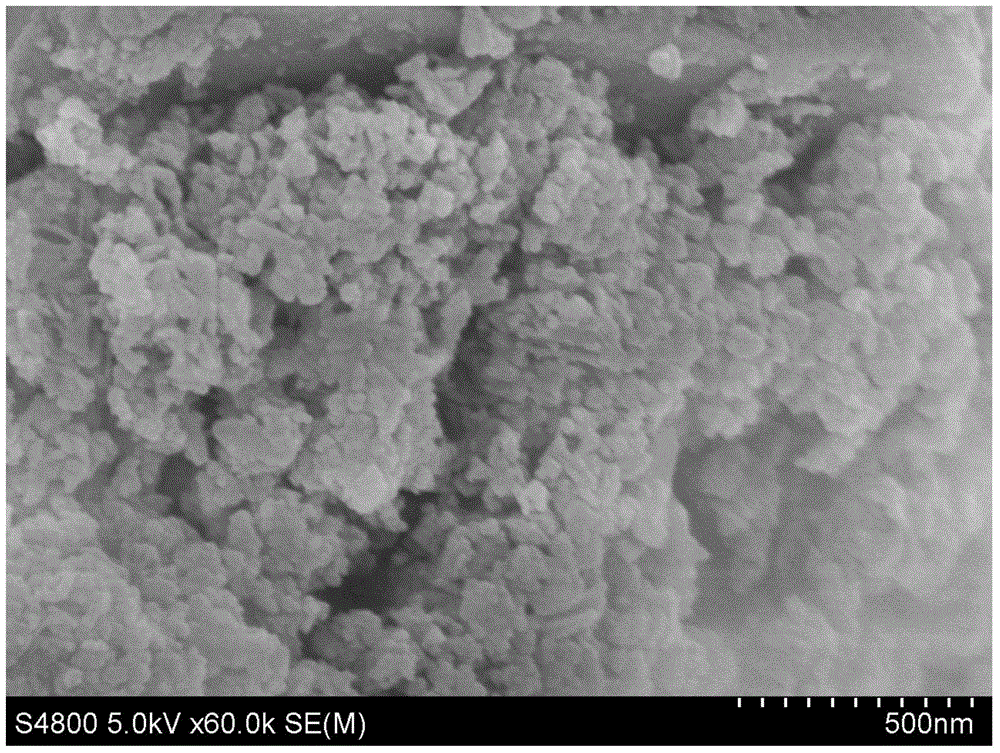

[0024] Specific embodiment one: present embodiment is a kind of content controllable mixed crystal form nano-calcium carbonate synthetic method, specifically completes according to the following steps:

[0025] One, configure calcium chloride-polyaspartic acid mixed solution: utilize calcium chloride, polyaspartic acid and deionized water to configure calcium chloride-polyaspartic acid mixed solution, and described calcium chloride- The concentration of calcium chloride in the polyaspartic acid mixed solution is 0.3mol / L, and the concentration of polyaspartic acid is M mg / L, wherein 0<M<2.5;

[0026] Two, configure sodium carbonate solution: dissolve sodium carbonate in deionized water to obtain sodium carbonate solution, and the concentration of sodium carbonate in the sodium carbonate solution is 0.3mol / L;

[0027] 3. Preparation of mixed microemulsion: 1. Weighing: Take Ag calcium chloride-polyaspartic acid mixed solution, Bg cyclohexane, Cg fatty alcohol polyoxyethylene et...

specific Embodiment approach 2

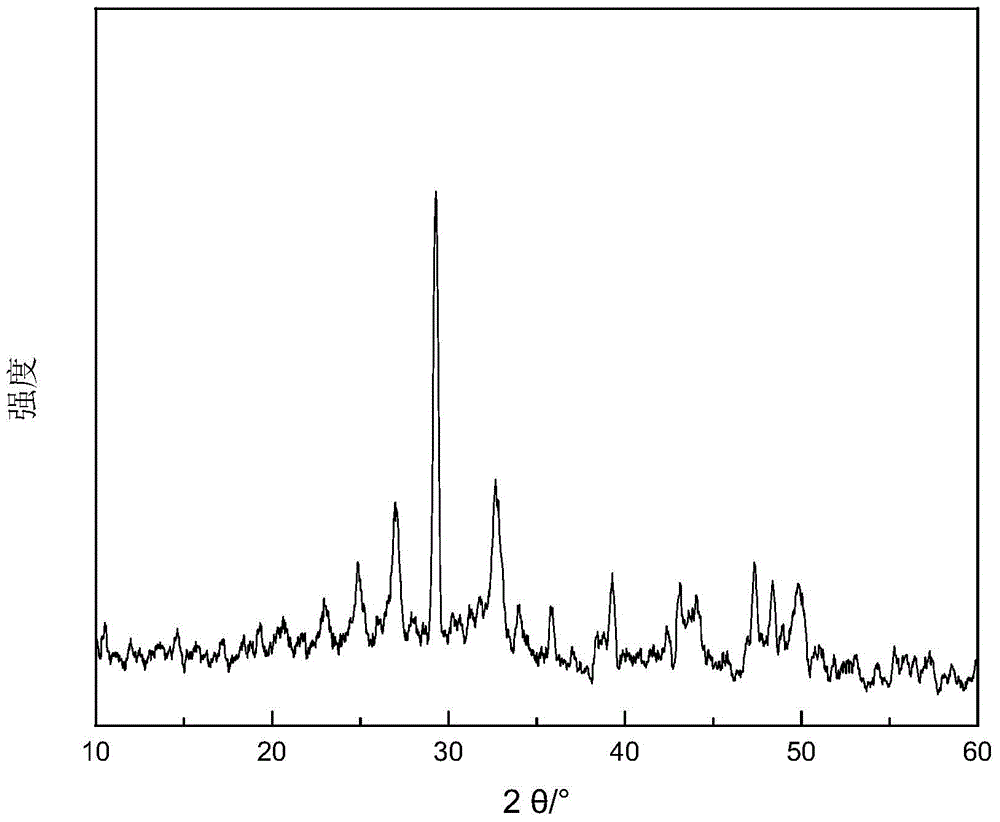

[0038] Specific embodiment two: the difference between this embodiment and specific embodiment one is: when the concentration of polyaspartic acid in the calcium chloride-polyaspartic acid mixed solution described in step 1 is 0.25mg / L, The content of the vaterite type calcium carbonate in the mixed crystal form of calcite and vaterite described in the fifth step is 73% to 76%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: the difference between this embodiment and specific embodiment one is: when the concentration of polyaspartic acid in the calcium chloride-polyaspartic acid mixed solution described in step 1 is 0.5mg / L, The content of the vaterite type calcium carbonate in the mixed crystal form of calcite and vaterite described in the fifth step is 80%-83%. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com