Vaterite calcium carbonate microspheres and preparation method thereof

A calcium carbonate and vaterite technology, applied in the field of biomedical materials, can solve problems such as waste water pollution in silk reeling plants, and achieve the effects of high biodegradability, high biocompatibility and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

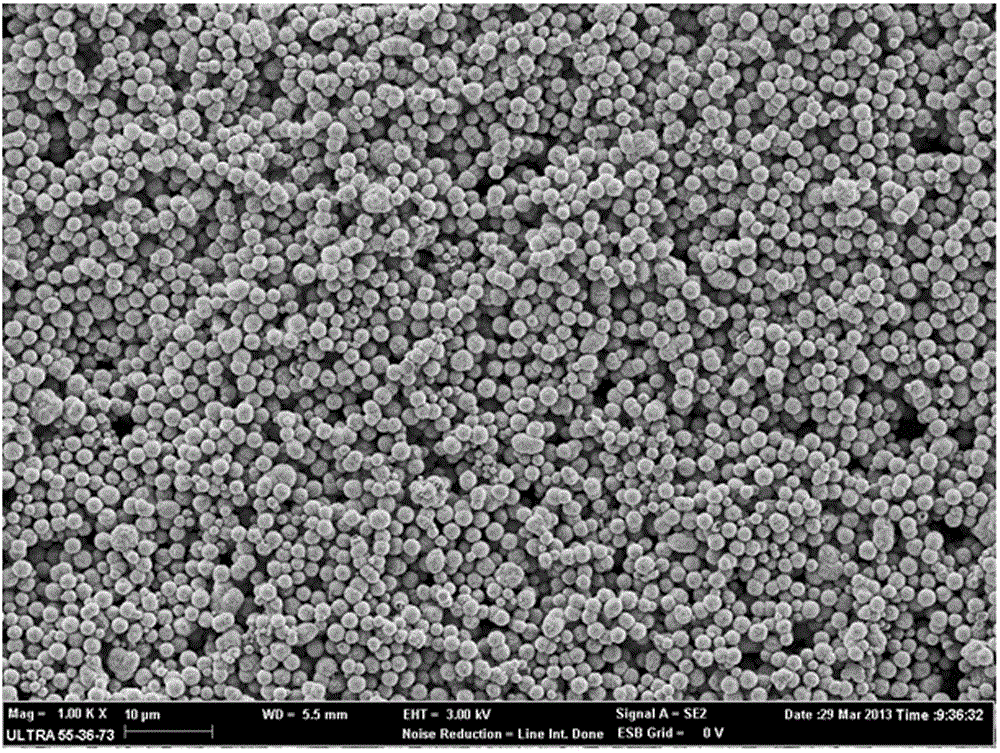

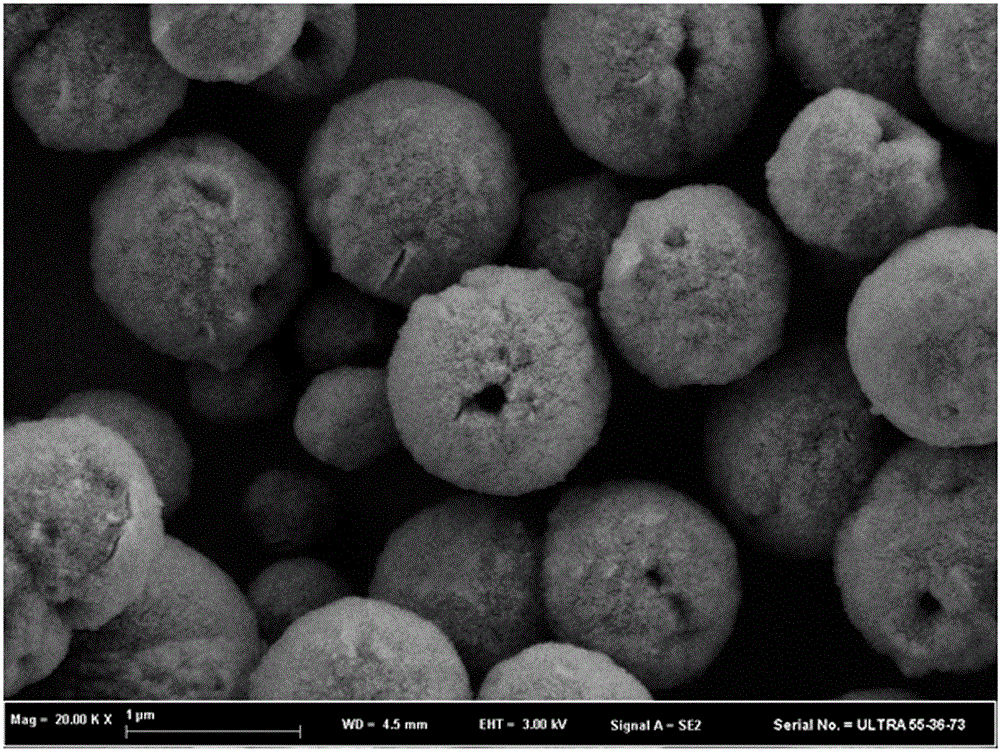

Embodiment 1

[0030] (1) Preparation of the calcium salt solution: Dissolve 2 mol of anhydrous calcium chloride in 1 L of deionized water to obtain a calcium chloride solution with a concentration of 2 mol / L for later use.

[0031] (2) Preparation of sodium carbonate aqueous solution: Dissolve 2 mol of sodium carbonate in 1L of deionized water to obtain a sodium carbonate solution with a concentration of 2 mol / L for later use.

[0032] (3) Sericin solution configuration: Take 25 mL of the above concentrated sericin solution concentrated to 30 mg / mL, and add 125 mL of deionized water. , to prepare 150 mL of sericin solution with a concentration of 5 mg / mL.

[0033] (4) Add 5 mL of the calcium chloride solution in step (1) and 5 mL of the sodium carbonate solution in step (2) dropwise into the sericin solution prepared in step (3) under stirring conditions, Stirring was continued for half an hour after the dropwise addition.

[0034] (5) The obtained precipitate was taken out by centrifugat...

Embodiment 2

[0036] Change the configuration of the calcium salt solution in step (1) to: 2 mol of calcium nitrate, dissolved in 1L of deionized water, to obtain a calcium nitrate solution with a concentration of 2 mol / L, and set aside.

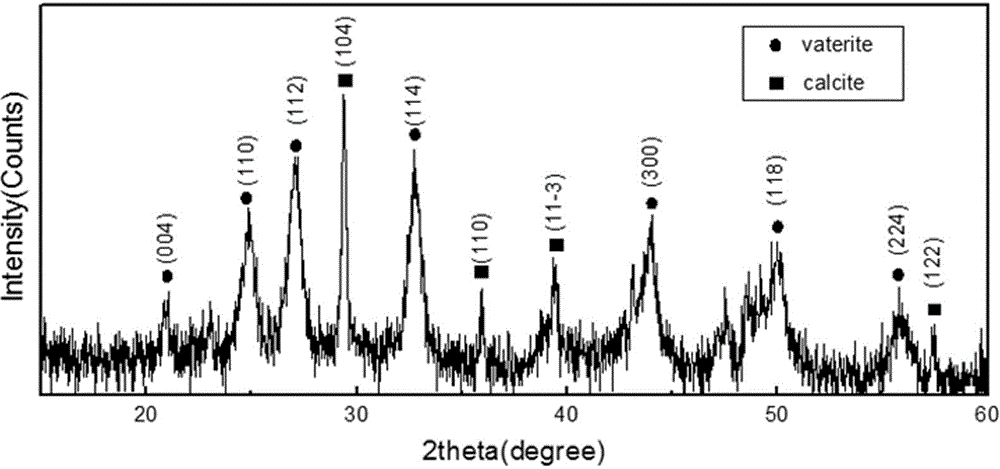

[0037] Subsequent steps are the same as in Example 1, and the obtained product has a particle size of about 1.3 μm microspheres, and the vaterite crystal content is greater than 80%.

Embodiment 3

[0039] Change the configuration of the carbonate solution in step (2) to: 2 mol of potassium carbonate is dissolved in 1 L of deionized water to obtain a potassium carbonate solution with a concentration of 2 mol / L for later use.

[0040] Subsequent steps are the same as in Example 1, and the obtained product has a particle size of about 1.2 μm microspheres, and the vaterite crystal content is greater than 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com