Polymer modified nano calcium carbonate novel product series

A technology of nano-calcium carbonate and polymer modifier, applied in the direction of calcium carbonate/strontium/barium, dyed polymer organic compound treatment, fibrous filler, etc. Large drop, limited effect, etc., to achieve huge application development potential, improved bending strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Weigh 75g of glycine to dissolve in a certain amount of water, then add 40g of sodium hydroxide to stir the reaction, and dilute to a 1L volumetric flask to prepare a 1mol / L sodium glycinate solution. Pour the sodium glycinate solution into a three-necked round-bottomed flask, introduce carbon dioxide gas, stir to absorb the carbon dioxide gas, and stop ventilation when the pH of the solution reaches 7.5 to obtain a carbon dioxide absorption solution of sodium glycinate.

[0075] Weigh 150g of glycine and dissolve it in a certain amount of water, then add 74g of calcium hydroxide / 106g of calcium hydroxide slag (the calcium hydroxide content in the calcium hydroxide slag is 70%), stir at 100rpm for 40min, filter to obtain a calcium glycinate solution, and then dilute to a volume of 1L Prepare a 1mol / L calcium glycinate solution in the bottle, pour the calcium glycinate solution into a 2000mL beaker, add 9g sodium lignin, then stir and mix for 5 minutes, slowly pour the carbo...

Embodiment 2

[0078] Weigh 75g of glycine to dissolve in a certain amount of water, then add 40g of sodium hydroxide to stir the reaction, and dilute to a 1L volumetric flask to prepare a 1mol / L sodium glycinate solution. Pour the sodium glycinate solution into a three-necked round-bottomed flask, introduce carbon dioxide gas, stir to absorb the carbon dioxide gas, and stop ventilation when the pH of the solution reaches 7.5 to obtain a carbon dioxide absorption solution of sodium glycinate.

[0079] Weigh 150g of glycine and dissolve it in a certain amount of water, then add 74g of calcium hydroxide / 106g of calcium hydroxide slag (the calcium hydroxide content in the calcium hydroxide slag is 70%), stir and react for 40 minutes, filter to obtain the calcium glycinate solution, and then dilute to a 1L volumetric flask , Made into 1mol / L calcium glycinate solution. Pour the calcium glycinate solution into a 2000mL beaker, add 4g E01 styrene-acrylic emulsion (50% solid content), stir and mix for...

Embodiment 3

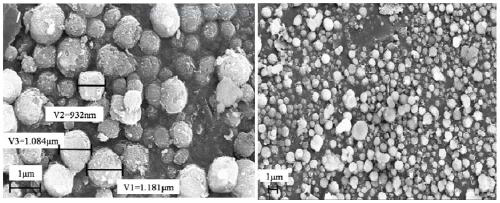

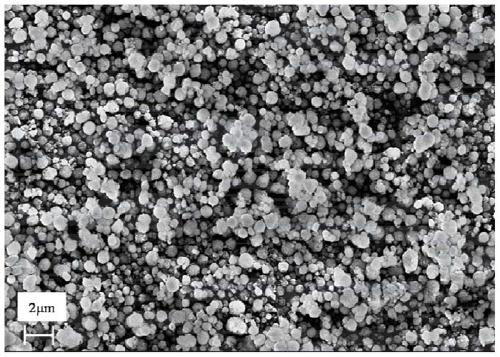

[0082] Weigh a certain amount of calcium hydroxide, add water to form a slurry with a concentration of 7%-10%, stir and mix well, and control the temperature below 40°C. Then, under stirring, add dropwise E01 styrene-acrylic emulsion (solid content 50%) to the calcium hydroxide slurry. The weight of the drop-wise E01 styrene-acrylic emulsion accounts for 1% of the theoretical mass of calcium carbonate. Stir for 2 minutes, and the temperature is controlled at room temperature. . Finally, carbon dioxide gas was introduced into the calcium hydroxide slurry to which the emulsion was added dropwise, and the carbonization reaction was carried out with stirring. The reaction temperature was 30°C. The reaction was stopped until the pH value of the solution dropped to 7. The obtained precipitate is suction filtered and washed to obtain a modified nano-calcite calcium carbonate paste product, and a powder product is obtained after drying.

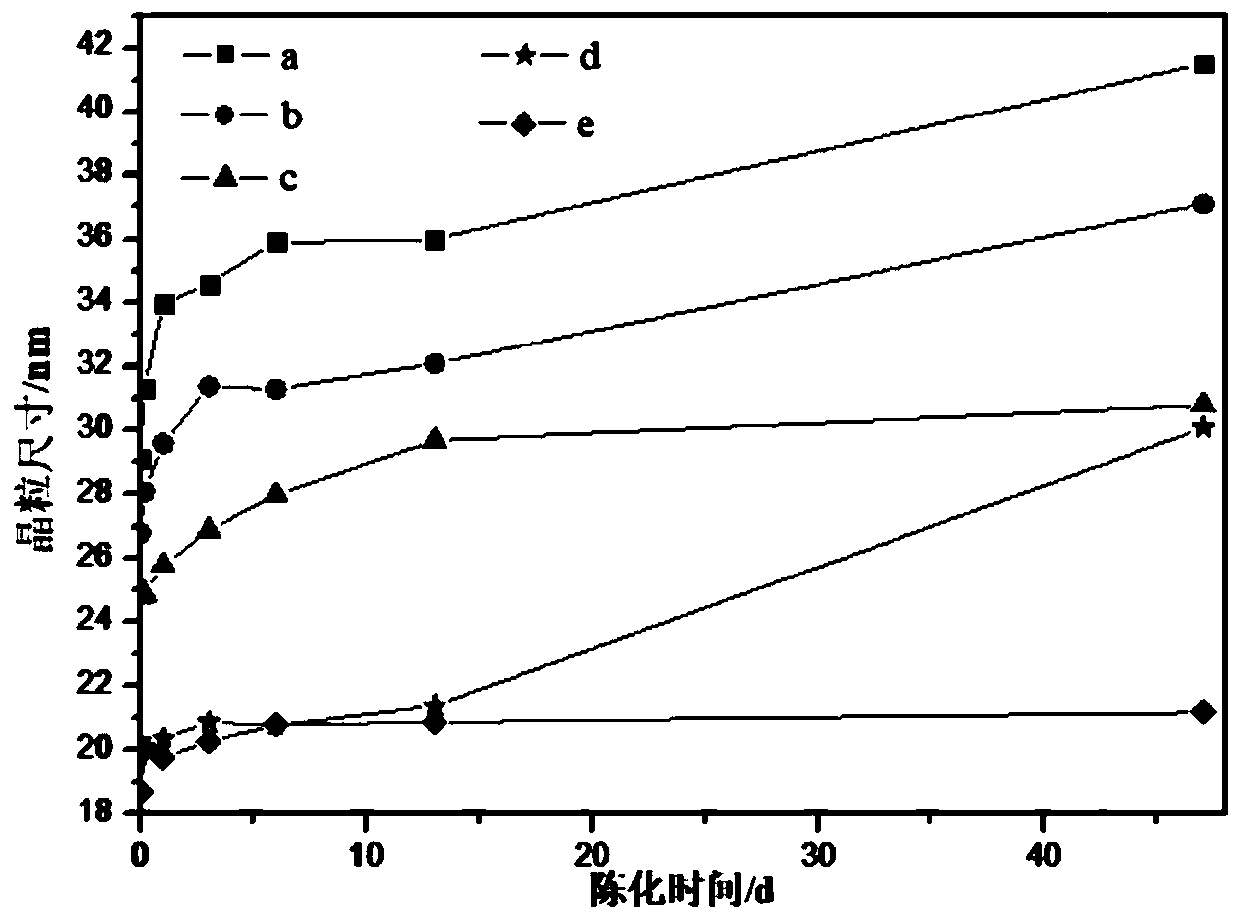

[0083] After analysis, the calcium carbonate pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com