Method for preparing single-crystal-form ball aragonite nano calcium carbonate through microemulsion system

A nano-calcium carbonate and microemulsion technology, applied in the field of nanomaterials, can solve problems such as preparing micron-scale vaterite-type calcium carbonate, and achieve the effects of easy industrialization and application, simple equipment and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

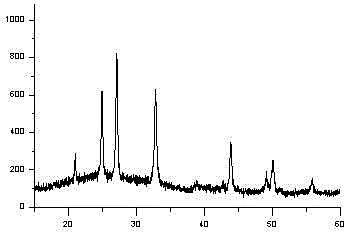

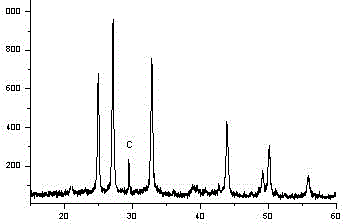

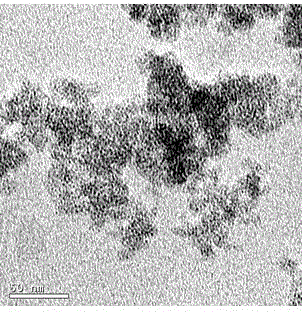

Image

Examples

Embodiment 1

[0030] (1) Preparation of microemulsion non-aqueous component system

[0031] At a temperature of 10°C, the non-aqueous components in the system are mixed and stirred evenly according to the mass ratio of Tuwen-80 emulsifier: n-butanol co-emulsifier: xylene oil phase in the ratio of 2:3:5;

[0032] (2) Preparation of calcium chloride microemulsion

[0033] the Prepare Calcium Chloride Solution

[0034] Dissolve calcium chloride in the water phase and stir evenly to prepare a calcium chloride aqueous solution with a concentration of 2.0M;

[0035] the Preparation of calcium chloride microemulsion

[0036] First step (2) -- The prepared calcium chloride aqueous solution is mixed with the microemulsion non-aqueous component system prepared in step (1), and stirred evenly. The mass ratio of each component after mixing is soil temperature-80 emulsifier: n-butanol co-emulsifier: two Toluene oil phase: calcium chloride is 2:3:5:0.35;

[0037] (3) Preparation of aqueous sodi...

Embodiment 2

[0052] (1) Preparation of microemulsion non-aqueous component system

[0053] At a temperature of 20°C, the non-water components in the system are mixed and stirred evenly according to the mass ratio of Tuwen-80 emulsifier: n-butanol co-emulsifier: xylene oil phase in the ratio of 2:8:10;

[0054] (2) Preparation of calcium chloride microemulsion

[0055] the Prepare Calcium Chloride Solution

[0056] Dissolve calcium chloride in the water phase and stir evenly to prepare a calcium chloride aqueous solution with a concentration of 2.0M;

[0057] the Preparation of calcium chloride microemulsion

[0058] First put step (2) -- The prepared calcium chloride aqueous solution is mixed with the microemulsion non-aqueous component system prepared in step (1), and stirred evenly. The mass ratio of each component after mixing is soil temperature-80 emulsifier: n-butanol co-emulsifier: two Toluene oil phase: calcium chloride is 2:8:10:0.61;

[0059] (3) Preparation of aqueous ...

Embodiment 3

[0074] (1) Preparation of microemulsion non-aqueous component system

[0075] At a temperature of 30°C, the non-water components in the system are mixed and stirred evenly according to the mass ratio of Tuwen-80 emulsifier: n-butanol co-emulsifier: xylene oil phase in the ratio of 2:3.5:5;

[0076] (2) Preparation of calcium chloride microemulsion

[0077] the Prepare Calcium Chloride Solution

[0078] Dissolve calcium chloride in the water phase and stir evenly to prepare an aqueous calcium chloride solution with a concentration of 2.5M;

[0079] the Preparation of calcium chloride microemulsion

[0080] First step (2) -- The prepared calcium chloride aqueous solution is mixed with the microemulsion non-aqueous component system prepared in step (1), and stirred evenly. The mass ratio of each component after mixing is soil temperature-80 emulsifier: n-butanol co-emulsifier: two Toluene oil phase: calcium chloride is 2:3.5:5:0.7;

[0081] (3) Preparation of aqueous so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com