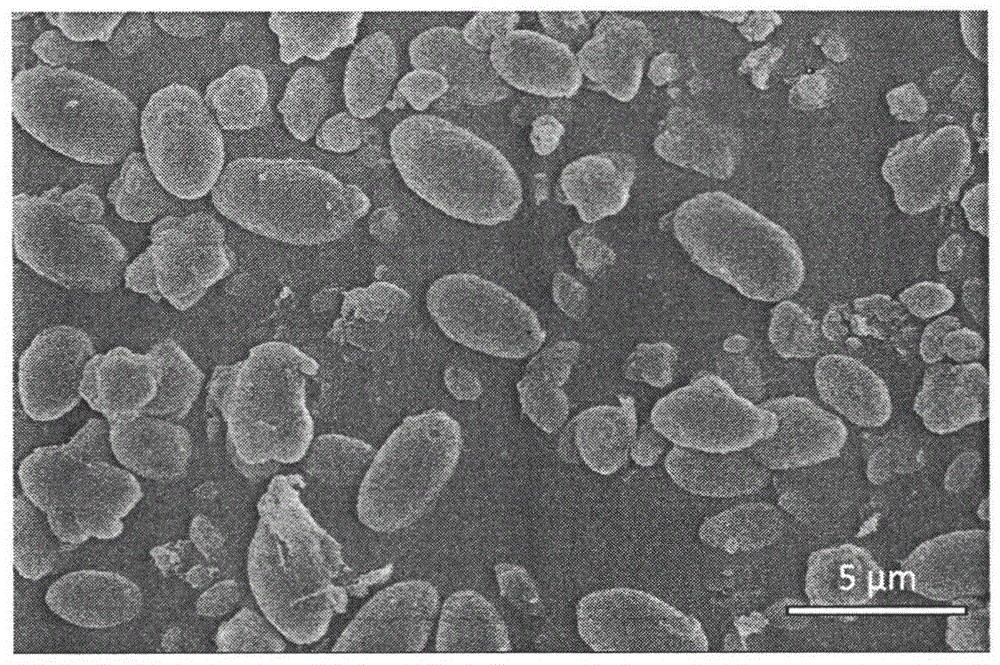

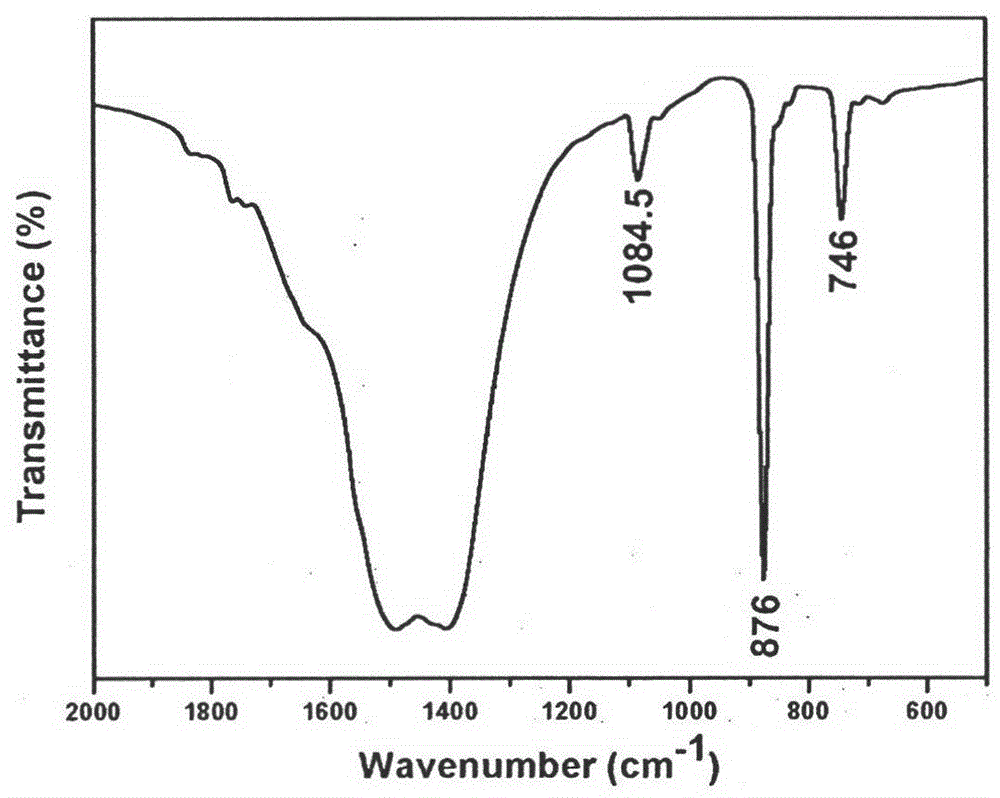

Micron spindle-fiber-like structure vaterite calcium carbonate preparation method

A technology of vaterite and calcium carbonate, applied in the direction of calcium carbonate/strontium/barium, etc., to achieve the effects of good repeatability, simple process and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] ①Dissolve 0.2g of Pluronic (F127) in 25ml of deionized water / ethanol=0.5 system, place at 25°C and stir for 10min to obtain a clear and transparent liquid A.

[0022] ②Add 0.312g of sodium dodecyl sulfate (SDS) to the clear and transparent liquid A, and continue to stir at 25°C until dissolved and mixed evenly to obtain a transparent solution B.

[0023] ③ 1.11g calcium chloride (CaCl 2 ) was dissolved in 10ml of deionized water, placed in an environment of 25°C, and stirred for 10 minutes to obtain a clear and transparent solution C.

[0024] ④ 1.06g potassium carbonate (Ka 2 CO 3 ) was dissolved in 10ml of deionized water, placed in an environment of 25°C, and stirred for 10min to obtain a clear and transparent solution D.

[0025] ⑤ Quickly add solution C to solution B, and stir the mixed solution in a water bath at 50°C for 5 minutes.

[0026] ⑥ Take 5ml of solution D and add it dropwise to the above mixed solution, place the mixed solution in an environment of ...

Embodiment 2

[0029] ① Dissolve 0.2g of Pluronic (F127) in 25ml of deionized water / ethanol = 0 system, place at 25°C, and stir for 10 minutes to obtain a clear and transparent liquid A.

[0030] ②Add 0.312g of sodium dodecyl sulfate (SDS) to the clear and transparent liquid A, and continue to stir at 25°C until dissolved and mixed evenly to obtain a transparent solution B.

[0031] ③ 1.11g calcium chloride (CaCl 2 ) was dissolved in 10ml of deionized water, placed in an environment of 25°C, and stirred for 10 minutes to obtain a clear and transparent solution C.

[0032] ④ 1.06g potassium carbonate (Ka 2 CO 3 ) was dissolved in 10ml of deionized water, placed in an environment of 25°C, and stirred for 10min to obtain a clear and transparent solution D.

[0033] ⑤ Quickly add solution C to solution B, and stir the mixed solution in a water bath at 50°C for 5 minutes.

[0034] ⑥ Take 5ml of solution D and add it dropwise to the above mixed solution, place the mixed solution in an environm...

Embodiment 3

[0037] ① Dissolve 0.2g of Pluronic (F127) in 25ml of deionized water / ethanol = 0.25 system, place at 25°C, and stir for 10 minutes to obtain a clear and transparent liquid A.

[0038] ②Add 0.312g of sodium dodecyl sulfate (SDS) to the clear and transparent liquid A, and continue to stir at 25°C until dissolved and mixed evenly to obtain a transparent solution B.

[0039] ③ 1.11g calcium chloride (CaCl 2 ) was dissolved in 10ml of deionized water, placed in an environment of 25°C, and stirred for 10 minutes to obtain a clear and transparent solution C.

[0040] ④ 1.06g potassium carbonate (Ka 2 CO 3 ) was dissolved in 10ml of deionized water, placed in an environment of 25°C, and stirred for 10min to obtain a clear and transparent solution D.

[0041] ⑤ Quickly add solution C to solution B, and stir the mixed solution in a water bath at 50°C for 5 minutes.

[0042] ⑥ Take 5ml of solution D and add it dropwise to the above mixed solution, place the mixed solution in an envir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com