Guided bone regeneration membrane and manufacturing method thereof

a bone regeneration and membrane technology, applied in the field of guided bone regeneration materials, can solve the problems of difficult to adopt this material difficult to handle these factors, and place a not-so-light burden on a patient, so as to improve the ability to adapt to an affected area, improve the ability to adapt to a large defect area, and improve the effect of cellular initial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0037]Manufacturing methods of guided bone regeneration membranes according to embodiments of the present invention will be illustrated with reference to several examples below. It should be noted, however, that these examples are included merely to aid in the understanding of the present invention and are not to be construed to limit the scope of the present invention.

[0038]Raw materials used in the examples are as follows:[0039]Silicon-releasing calcium carbonate (Si—CaCO3): Calcium carbonate of vaterite phase having a silicon content of 2.9 wt % prepared by using slaked lime (Microstar T; purity 96% or more; Yabashi Industries Co., Ltd., Japan), methanol (analytical grade reagent; purity 99.8% or more; Kishida Chemical Co., Ltd., Japan), γ-aminopropyltriethoxysilane (TSL 8331; purity 98% or more; GE Toshiba Silicones Co., Ltd., Japan), and carbon dioxide gas (high-purity liquefied carbon dioxide gas; purity 99.9%; Taiyo Kagaku Kogyo K.K.);[0040]Poly(lactic acid) (PLA): PURASORB P...

example 2

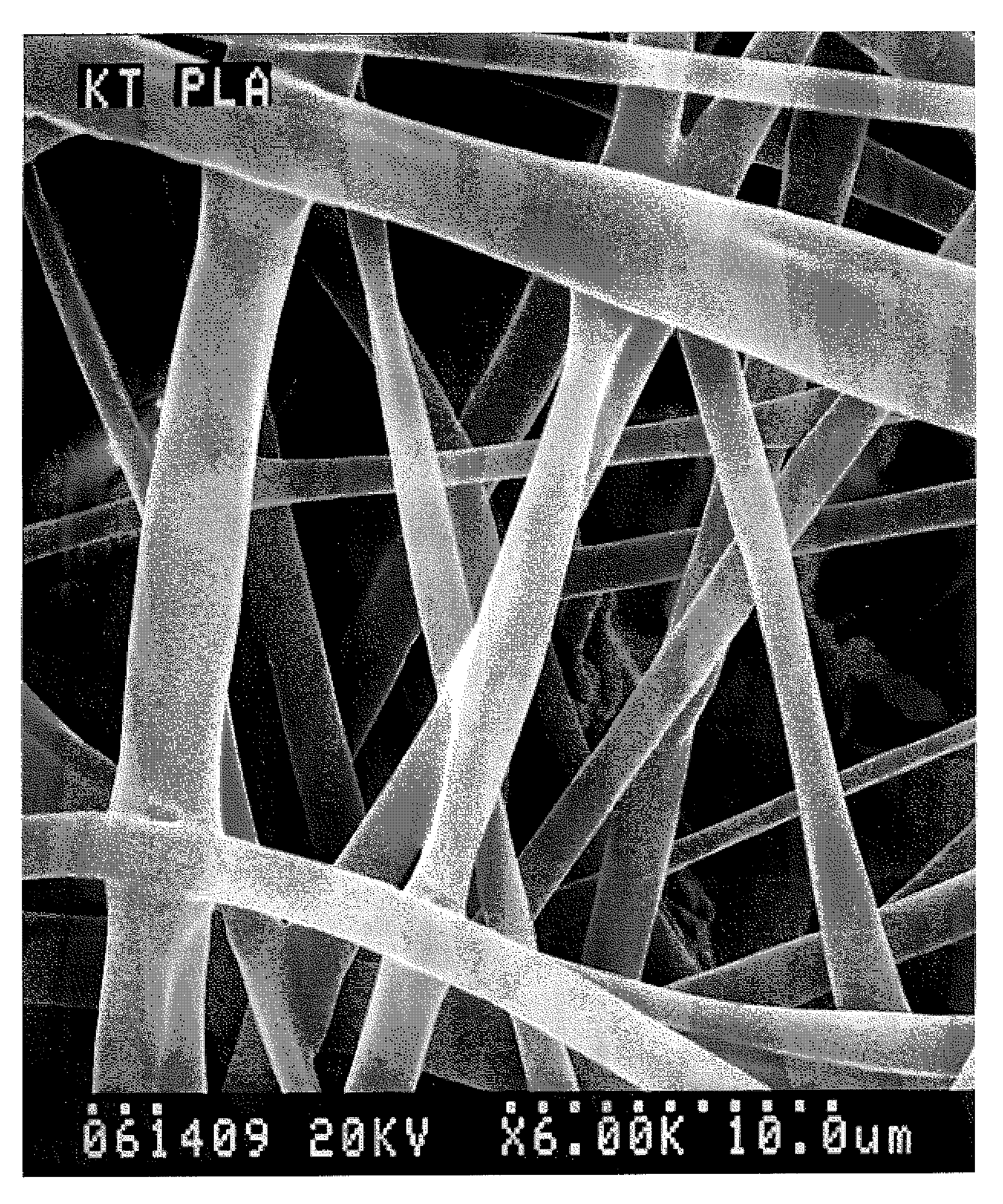

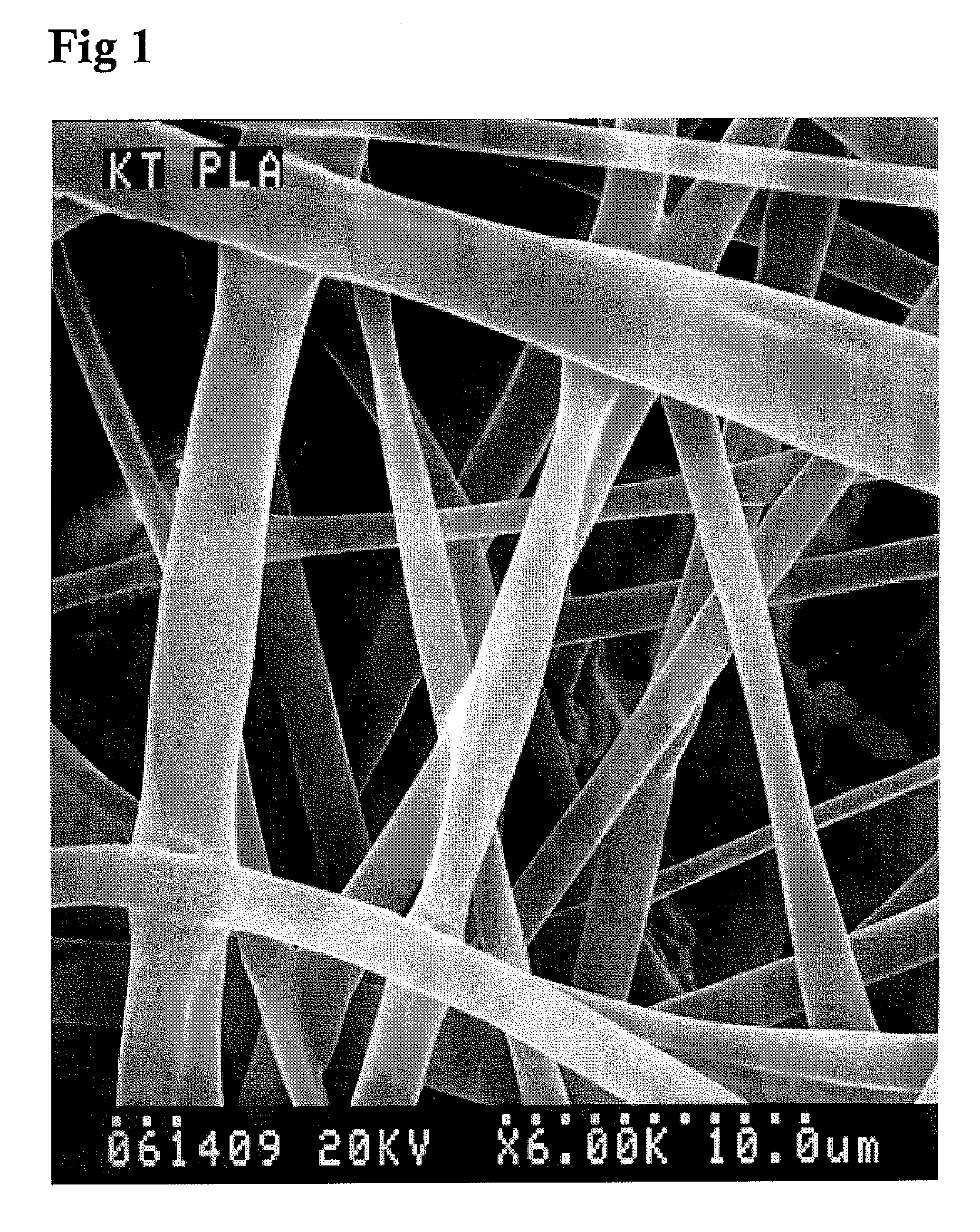

[0047]A spinning solution having a PLA content of 9.0 wt % was prepared by mixing 9 g of PLA and 91 g of CHCl3. Using this spinning solution, a PLA layer was prepared by electrospinning.

PLA Layer Preparation Conditions

[0048]In this example, the spinning solution feed rate is 0.05 ml / min, the applied voltage is 20 kV, and the distance between the nozzle and collector is 15 cm. The nozzle is fixed, so is the plate collector. The spinning time is 60 minutes.

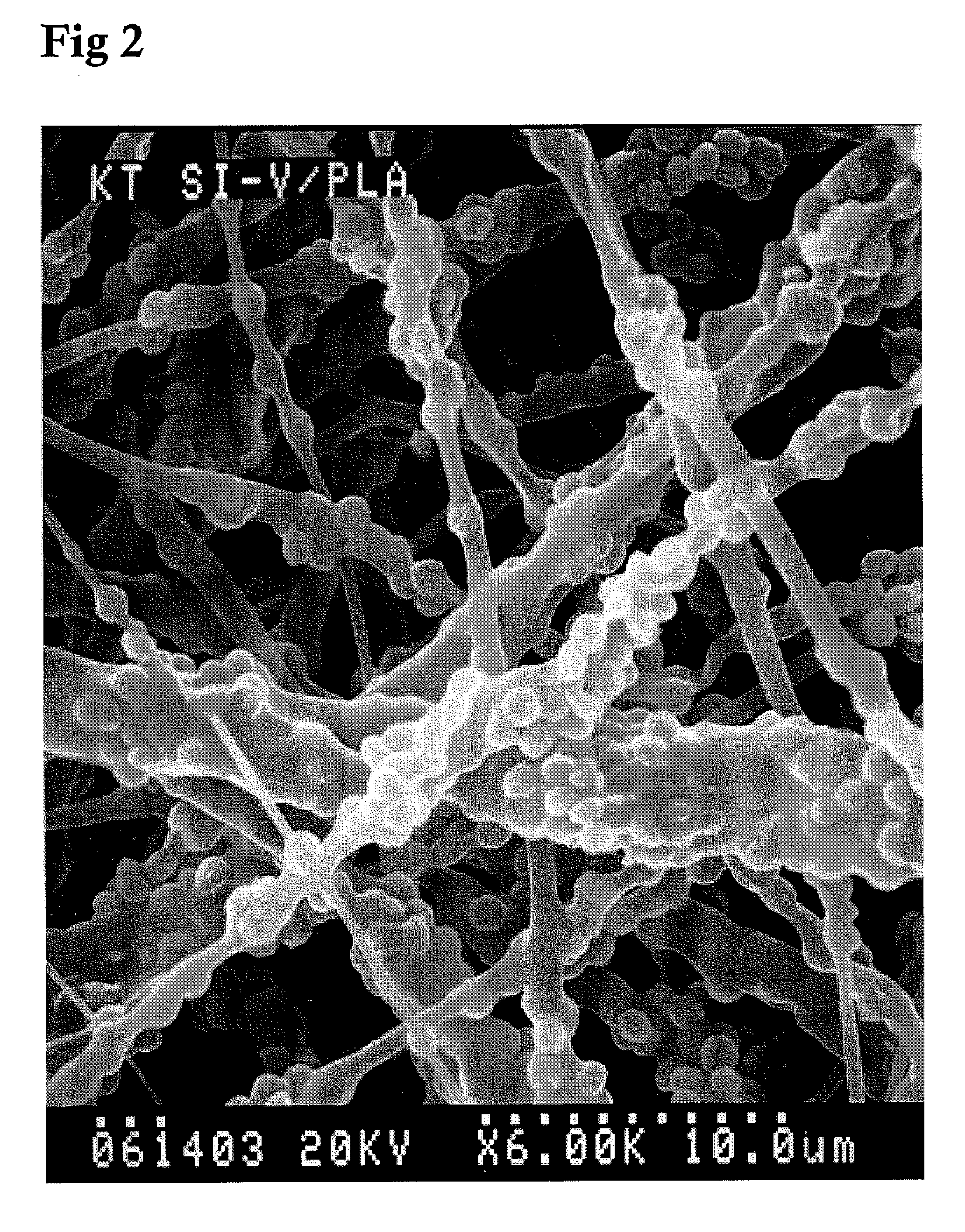

[0049]Separately, PLA and Si—CaCO3 were kneaded in a heating kneader at 200° C. for 15 minutes to give a Si—CaCO3 / PLA composite containing 60 wt % of Si—CaCO3. A spinning solution having a Si—CaCO3 content of 13.0 wt % and a PLA content of 8.7 wt % was prepared by mixing 25 g of the Si—CaCO3 / PLA composite and 90 g of CHCl3. Using this spinning solution, a Si—CaCO3 / PLA layer was prepared by electrospinning.

Si—d CaCO3 / PLA Layer Preparation Conditions

[0050]In this example, the spinning solution feed rate is 0.05 ml / min, the applied vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com