Filling method capable of exploring while filling coal mine goaf

A technology of mining and filling, goaf, applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve the problems of wasting water resources, high filling cost, low filling capacity, etc., to reduce labor intensity and filling strength. High, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

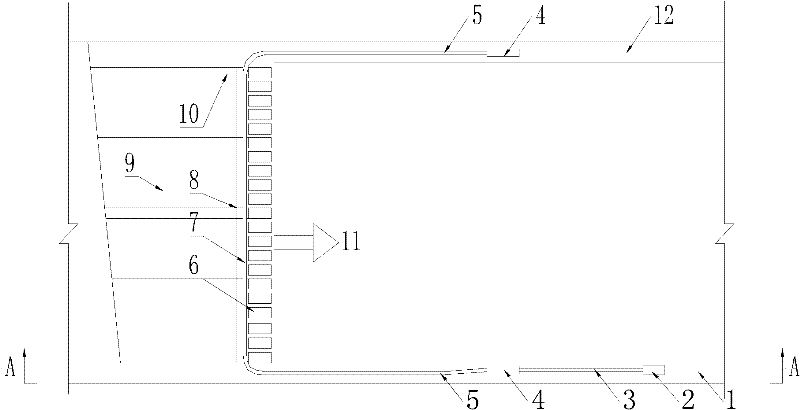

[0048] Example 1: A certain working face of Beizao Coal Mine of Shandong Longkou Coal Industry Group

[0049] Mining conditions of Beizao Coal Mine: Mining coal seam thickness is 3m (medium), burial depth is 260m (shallow), coal seam roof rock has high compressive and tensile strength, mining working face length is 150m (commonly adopted), working face support equipment 6 The control top distance is 4.5m (commonly adopted), and the direction of longwall fully mechanized mining;

[0050] 1. Filling parameters of the coal mine working face 11: the number of filling support walls 10 is 15 groups, the distance between groups is 9m, and the width is 1.5m.

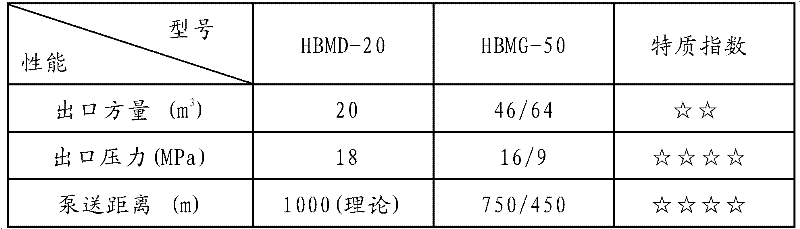

[0051] 2. According to the mining process of the working face 11, prepare paste-like material 2, filling pump 4, filling pipeline and accessories;

[0052] ①Use all-sand soil consolidation material as cement, industrial waste or river sand as aggregate, mix 22% fine-grained sand (not greater than 37μm) in the aggregate, and mak...

Embodiment 2

[0061] Example 2: Shanxi Lingshi Tianju Xinhuiyuan Coal Mine

[0062] Mining conditions of Xinhuiyuan Coal Mine: the thickness of the mining coal seam is 1.75m (very thin), the burial depth is 200m (shallow), the compressive and tensile strength of the rock on the roof of the coal seam is high, the length of the mining face is 100m (commonly adopted), the working face supports Protective equipment 6 control top distance 3m (commonly used), and the direction of longwall fully mechanized mining;

[0063] 1. Filling parameters of coal mine working face 11: 12 groups of filling support walls 10, group spacing 7.5m, width 1.5m.

[0064] 2. According to the mining process of the working face 11, prepare paste-like material 2, filling pump 4, filling pipeline and accessories;

[0065] ①Use all-sand soil consolidation materials as cement, industrial waste or river sand as aggregate, and add 28% fine-grained sand (not greater than 37μm) to the aggregate to make the concentration 76% a...

Embodiment 3

[0074] Example 3: Lujialiang Coal Mine, Laogaochuan Township, Fugu County, Shaanxi Province

[0075] Mining conditions of Lujialiang Coal Mine: the thickness of the mining coal seam is 4.5m (thick), the burial depth is 600m (deep), the compressive and tensile strength of the rock on the roof of the coal seam is high, the length of the mining face is 180m (commonly adopted), and the supporting equipment of the working face 6. The control top distance is 5m (commonly adopted), and the direction is longwall fully mechanized mining;

[0076] 1. Filling parameters of the coal mine working face 11: 20 groups of filling support walls 10, the group spacing is 7.5m, and the width is 3m.

[0077] 2. According to the mining process of the working face 11, prepare paste-like material 2, filling pump 4, filling pipeline and accessories;

[0078] ①Use all-sand soil consolidation materials as cement, industrial waste or river sand as aggregate, and add 15% fine-grained sand (not greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com