Swing arm type automatic bagging mechanism of valve bag filling machine

A valve bag and filling machine technology, applied in the field of swing arm type automatic bagging mechanism, can solve the problems of high workload of workers, restricted filling efficiency, and difficulty in ensuring workers' health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

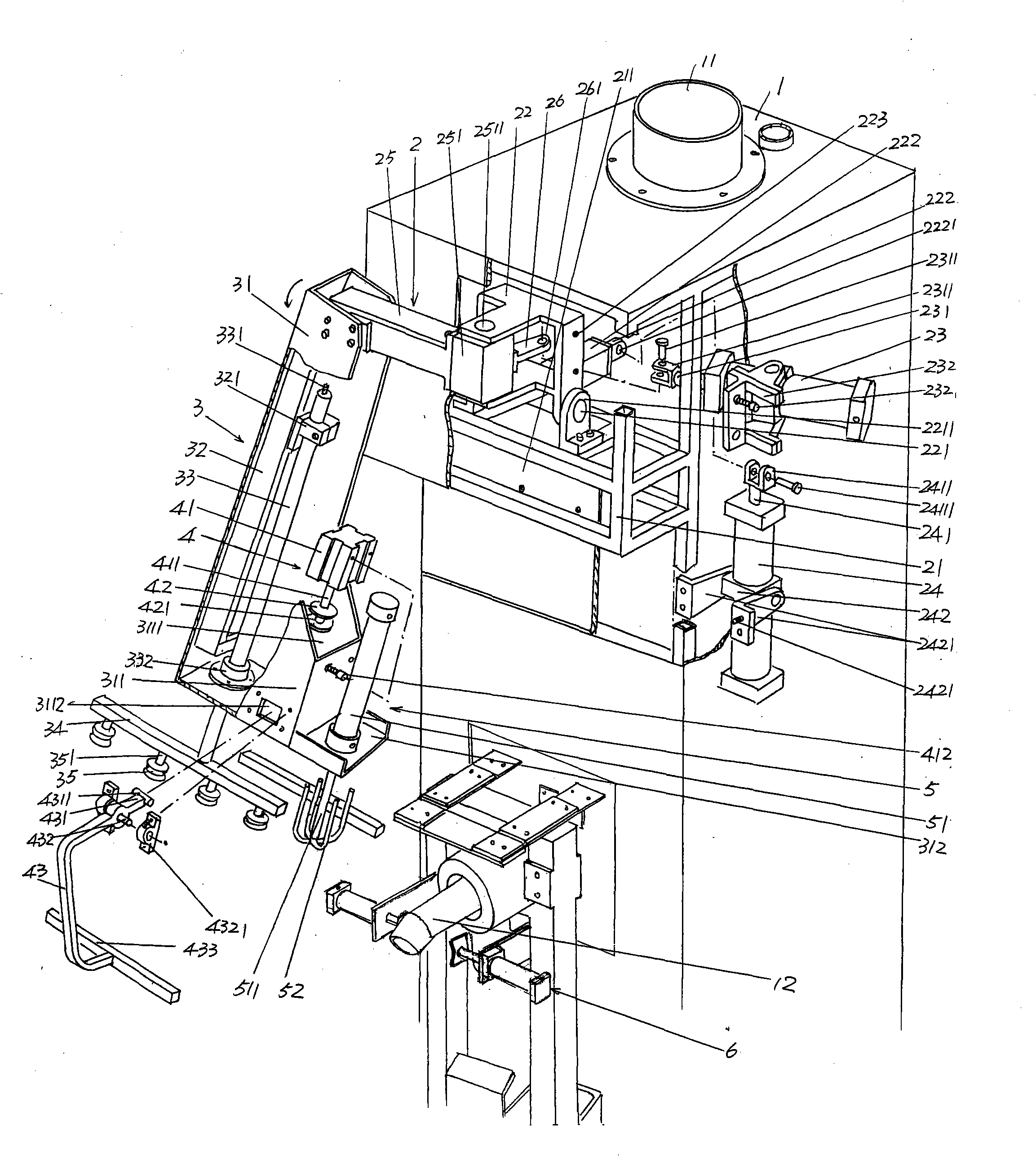

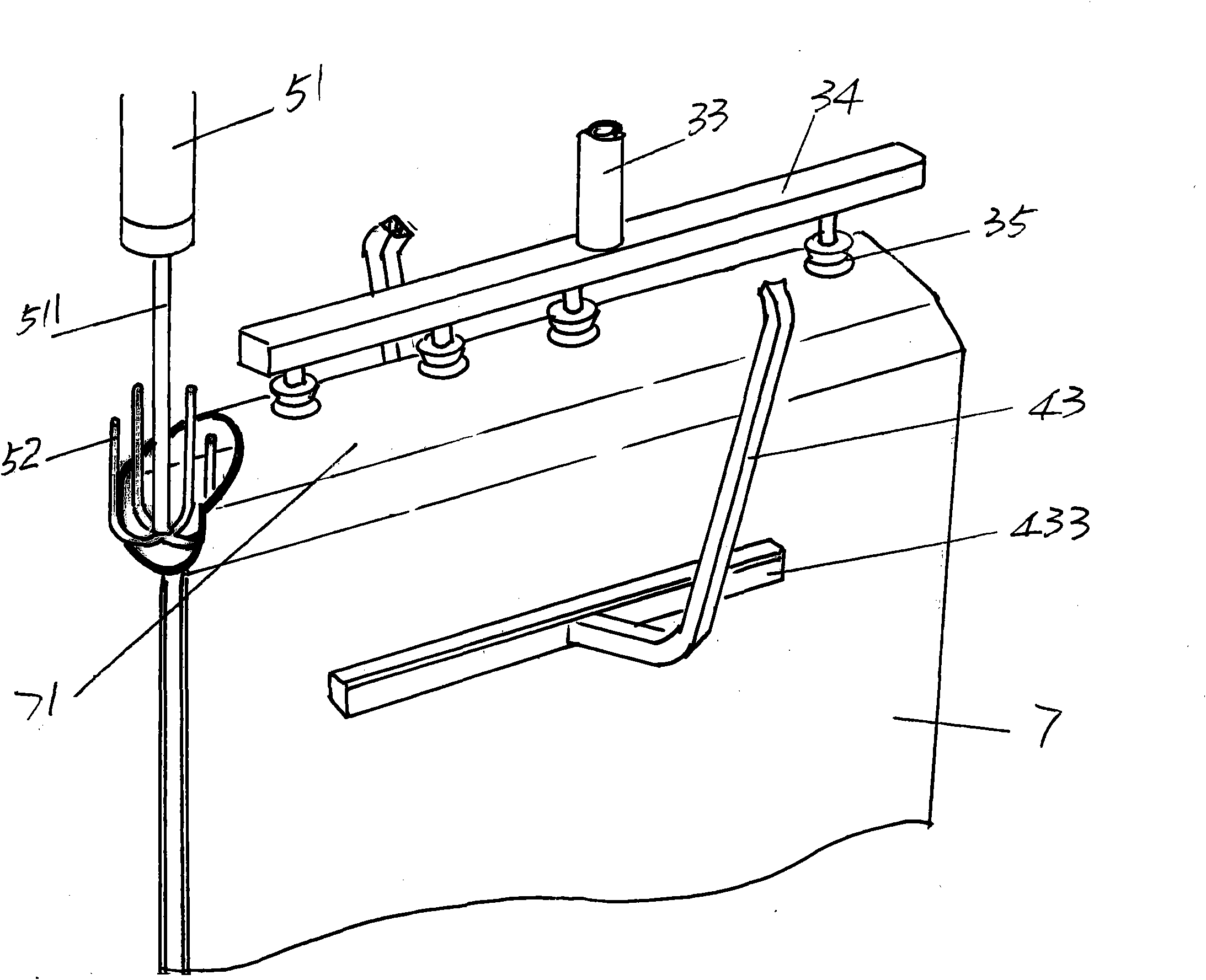

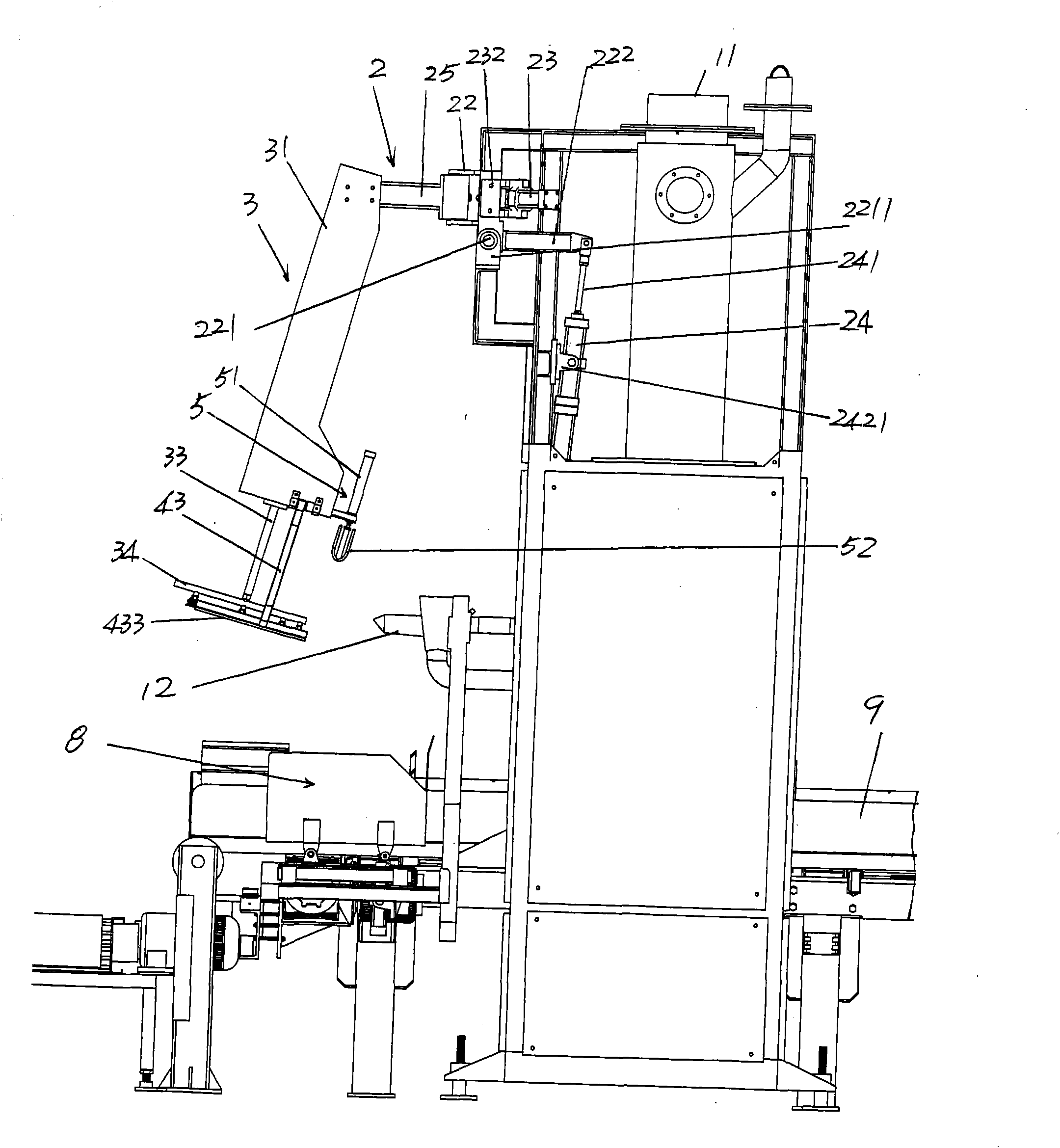

[0023] please see figure 1 , shows the frame 1 of the valve bag filling machine, the top of the frame 1 has an inlet 11 and the lower part of the side facing outwards in use has a discharge pipe 12 . The swing arm type automatic bagging mechanism provided by the present invention includes a swing arm actuating device 2, a valve pocket extracting device 3, a valve pocket opening holding device 4 and a valve pocket opening device 5, and the applicant will describe each device below .

[0024] The preferred but not limited structure of the swing arm actuating device 2 provided by the present invention is as follows: including a support frame 21, a swing arm frame 22, first and second action cylinders 23, 24, 25 turns of rotation and a connecting arm 26, the support frame 21 is fixed on one side of the upper part of the height direction of the frame 1, more precisely, the position of the support frame 21 on the frame 1 is on the same side as the aforementioned discharge pipe 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com