Composite slug deep water plugging method for oil pool with high water content

A composite section, water-containing oil technology, applied in drilling compositions, chemical instruments and methods, earthwork drilling, etc. Non-toxic and environmentally friendly, prolonging the validity period of water plugging, and excellent performance of plugging agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]A composite slug deep water plugging method for high water-cut oil reservoirs, which is characterized by using different plugging agent characteristics to perform composite plugging, high-strength plugging agent is used in the near-wellbore zone, and medium-strength plugging agent is used in the transition zone , the low-strength plugging agent is designed to slug in the far well area; the high-strength plugging agent uses foaming gel plugging agent, the medium-strength plugging agent uses inorganic chromium jelly plugging agent, and the low-strength plugging agent uses phenolic jelly plugging agent .

[0040] Phenolic jelly plugging agent is obtained by crosslinking emulsion polymer and pre-polymerized phenolic resin; the preparation process is to use water-in-water polyacrylamide emulsion with a concentration of 1-3%, stir and dissolve; then add a concentration of 0.5- 1.0% prepolymerized phenolic resin, and finally add 0.01-0.05% sodium thiosulfate stabilizer, stir we...

Embodiment 2

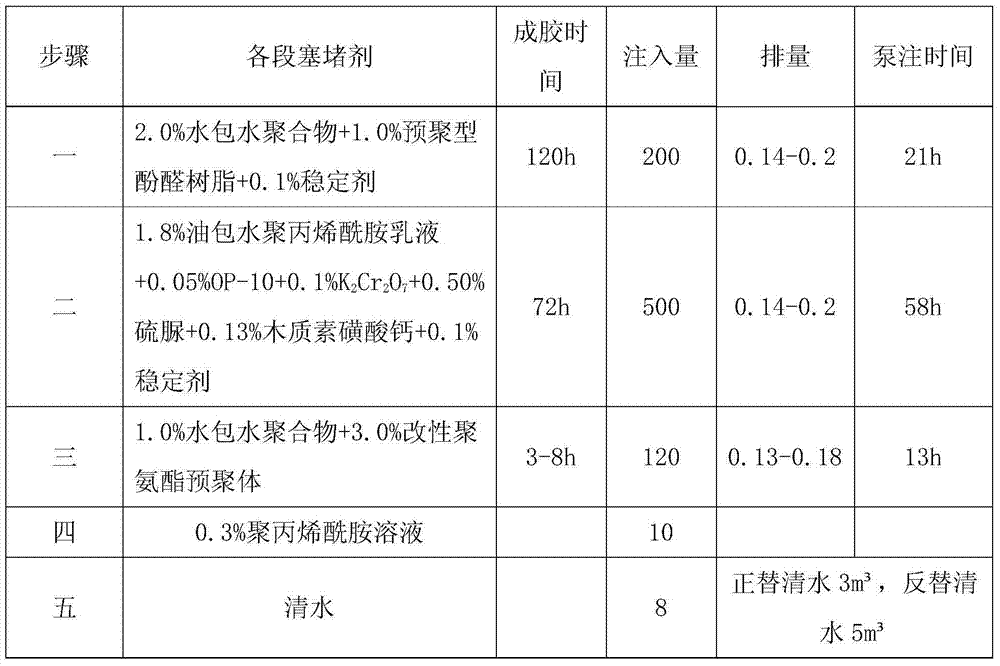

[0045] A composite slug deep water shutoff method for high water cut oil reservoirs, the specific implementation process of the composite slug of the water shutoff technology is as follows:

[0046] Pre-slug: Select phenolic gel plugging agent; use water-in-water emulsion with a concentration of 2.0%, stir to fully dissolve; then add prepolymerized phenolic resin with a concentration of 1.0%, and finally add 0.1%, and stir evenly. Phenolic resin jelly. The jelly plugging agent adopts shear-resistant water-in-water polyacrylamide emulsion, which has strong shear resistance; gelation time is 120h, gelation strength D (gel code), good elasticity; temperature resistance 70-120℃, 80 ℃ Aging is stable for 180 days without gel breakage.

[0047] Transition slug: choose inorganic chromium jelly plugging agent; use water-in-oil polyacrylamide emulsion with a concentration of 1.5-2.0%, then add a surfactant with a concentration of 0.05% OP10, stir to dissolve; then add a concentration ...

Embodiment 3

[0050] A composite slug deep water plugging method for high water-cut oil reservoirs. The plugging ability of the jelly plugging agent is evaluated by using sand-filled pipe cores, and the performance of the inorganic chromium-based jelly plugging agent is determined.

[0051] The plugging agent formula is 1.8% water-in-oil emulsion polyacrylamide+0.05%OP-10+0.1%K 2 Cr 2 o 7 + 0.50% thiourea + _0.13% calcium lignosulfonate + 0.1% sodium thiosulfate stabilizer.

[0052] The experimental process is as follows: select three parallel sand filling pipes (φ38*500mm), design them as high, medium and low permeability respectively, and measure the permeability k before plugging by water flooding until the pressure is stable. wo ; Then prepare the above formula jelly, inject 0.4PV, and then inject 0.1PV water for over-displacement, then keep the sand-packed pipe in an 80°C thermostat for 3 days, and after the plugging agent is completely gelled, water flood it again until the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com