Filling pipe string and sand control completion method

A technology for a pipe string and an outer pipe string is applied in the fields of filling pipe strings and sand control and completion, and can solve the problems of poor sand control and water control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

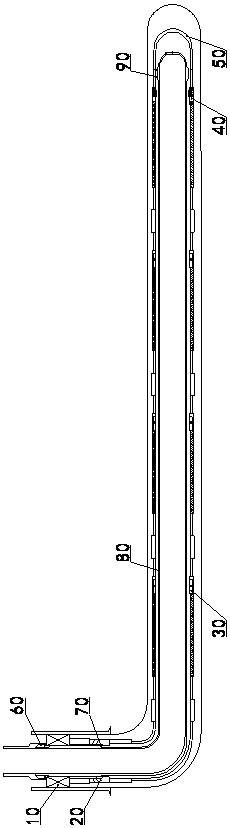

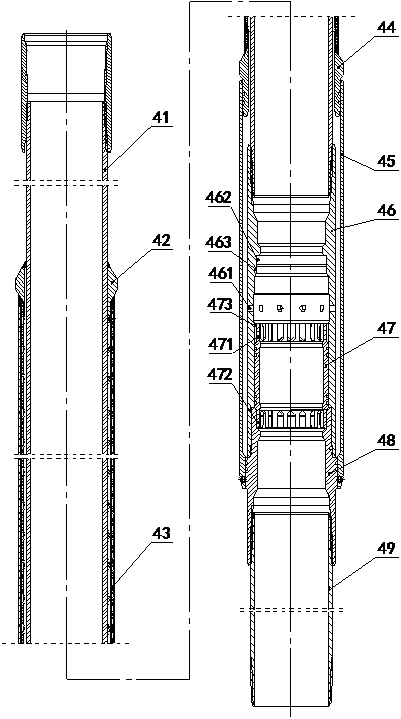

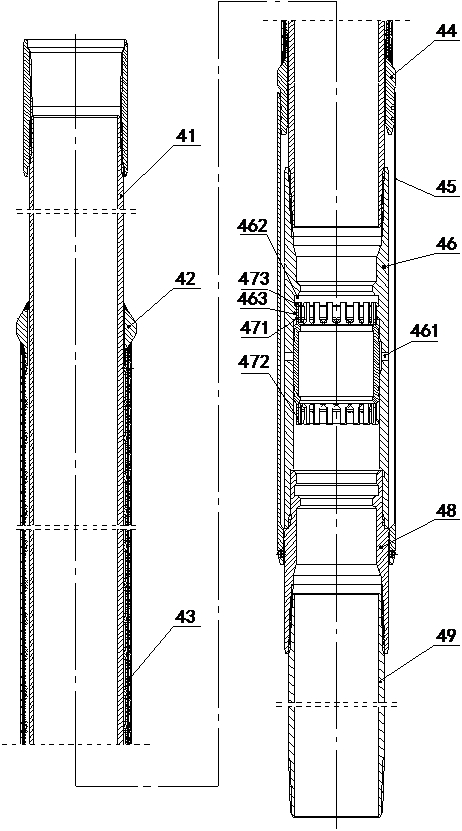

[0034] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention provides a filling pipe string, including an outer pipe string, the outer pipe string includes a filling tool 20, a water control screen 30 and a sliding sleeve screen 40, and the upper end of the water control screen 30 and the filling tool 20 The lower end of the water control screen pipe 30 is connected with the sliding sleeve screen pipe 40. A guide shoe 50 is connected to the bottom of the sliding sleeve screen pipe 40 .

[0035]By setting the packing tool 20, the water control screen 30 and the sliding sleeve screen 40, the packing tool 20 can be used to carry out gravel packing on the packing string outside the water control screen 30 and the wellbore annulus, and the gravel is controlled by the water control screen. 30 is blocked outside the water control screen 30, a small part of the filling liquid enters the water control screen 30 and returns, and most of the filling liquid returns...

Embodiment 2

[0057] The sand control completion method provided in this embodiment adopts the filling string of the aforementioned embodiment, and includes the following steps:

[0058] After the filling string is put in place, throw the ball, and press it, set the top packer 10, continue to press, open the filling port of the filling tool 20, turn the string forward before filling, and throw it back. Then, the sand control pump is used to fill the water control screen 30 filling pipe string and the annulus of the borehole wall, the gravel is blocked by the water control screen 30 outside the water control screen 30, and a small part of the filling fluid passes through the water control screen 30 The hole of the water control valve enters in the water control screen pipe 30, and returns through the flushing pipe 80, and most of the filling liquid passes through the sliding sleeve screen pipe 40, enters the flushing pipe 80 and returns.

[0059] Specifically, the filling liquid passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com