Backboard for solar battery and solar battery assembly

A technology for solar cells and backplanes, applied in electrical components, applications, circuits, etc., can solve problems such as poor hydrolysis resistance, achieve good weather resistance, improve power generation efficiency, and excellent acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

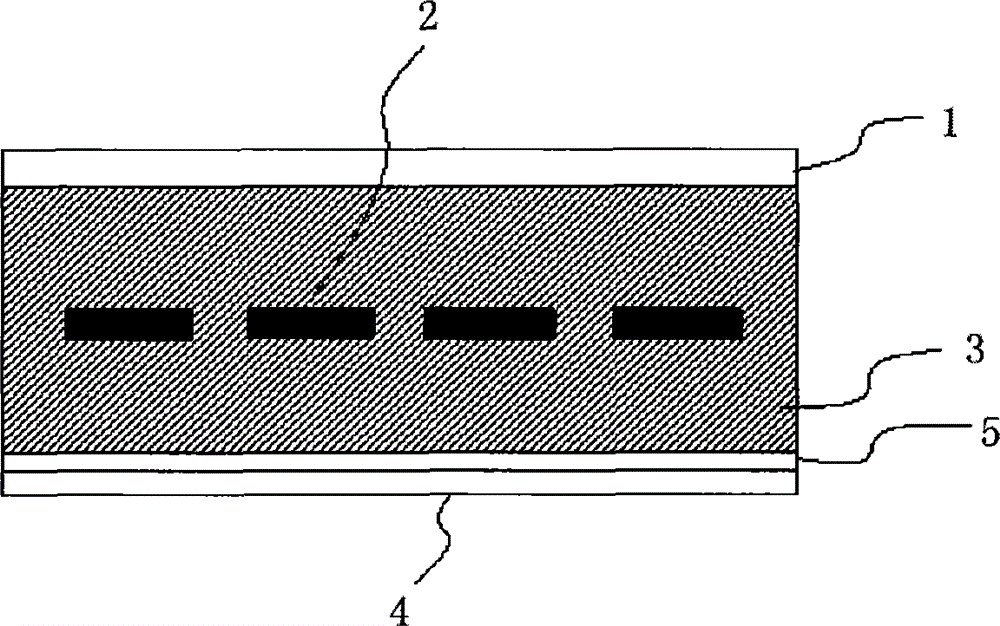

Image

Examples

Embodiment

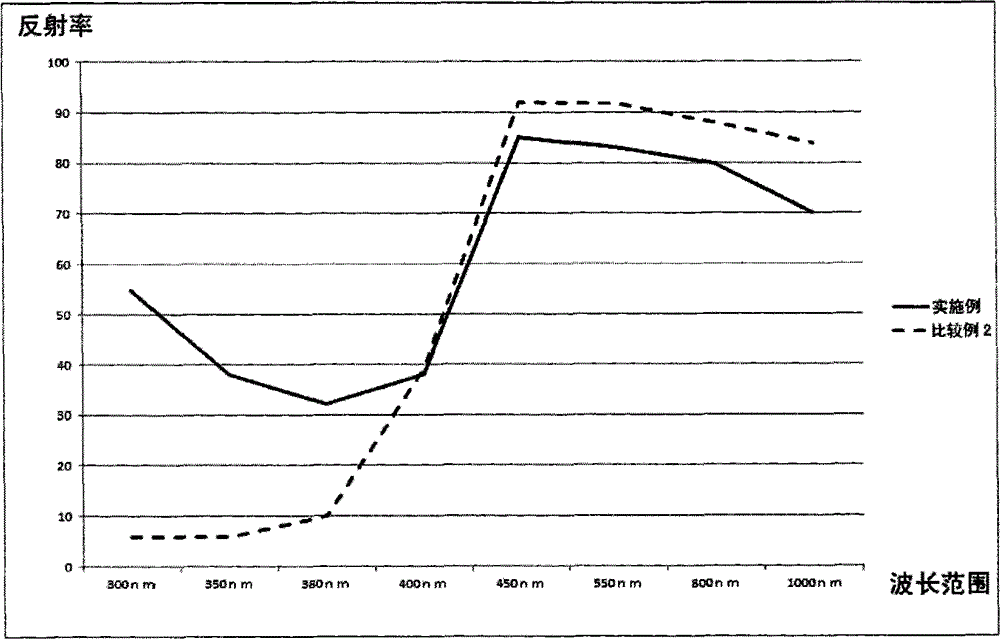

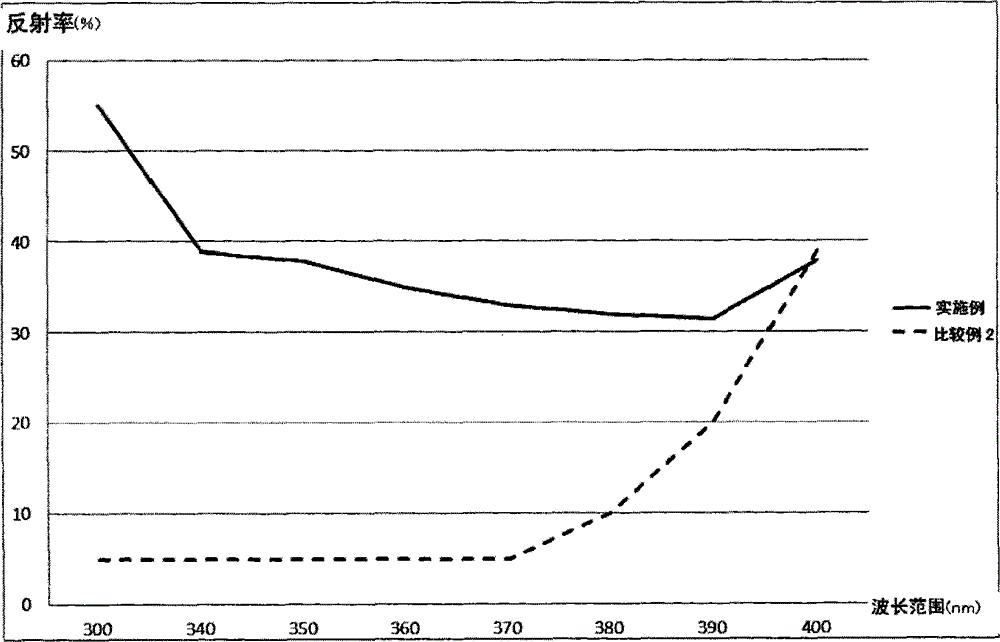

[0097] Hereinafter, examples of the present invention will be described in detail.

[0098] Example

[0099] On one side of a polyethylene naphthalate (PEN) substrate (TEONEX manufactured by Teijin DuPont Films Japan Limited) with a thickness of 250 μm, a white resin composition was printed by screen printing so that the dry coating film was 30 μm, This was heated at 120 degreeC for 60 minutes, it was thermally cured, and the test piece which has a white layer was produced.

[0100]

[0101] A white resin composition was prepared by mixing and stirring the following components.

[0102] NIPPORAN 136 (manufactured by NIPPON POLYURETHANE INDUSTRY CO.LTD.) 100 parts by weight (thermoplastic resin)

[0103] TIPAQUE CR-90 (manufactured by Ishihara Sangyo Co., Ltd.) 1000 parts by weight (titanium oxide)

[0104] Aluminum hydroxide 20 parts by weight

[0105] Takenate R600 (manufactured by Mitsui Chemicals Co., Ltd.) 10 parts by weight (isocyanate compound)

[0106] 20 parts b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com