Rubber sealing ring defect detection method based on deep learning

A rubber sealing ring and deep learning technology, applied in image analysis, image enhancement, instruments, etc., can solve the problems of poor stability of visual inspection method, high detection pressure, easy eye fatigue, etc., achieve accurate model recognition, effective regression, and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

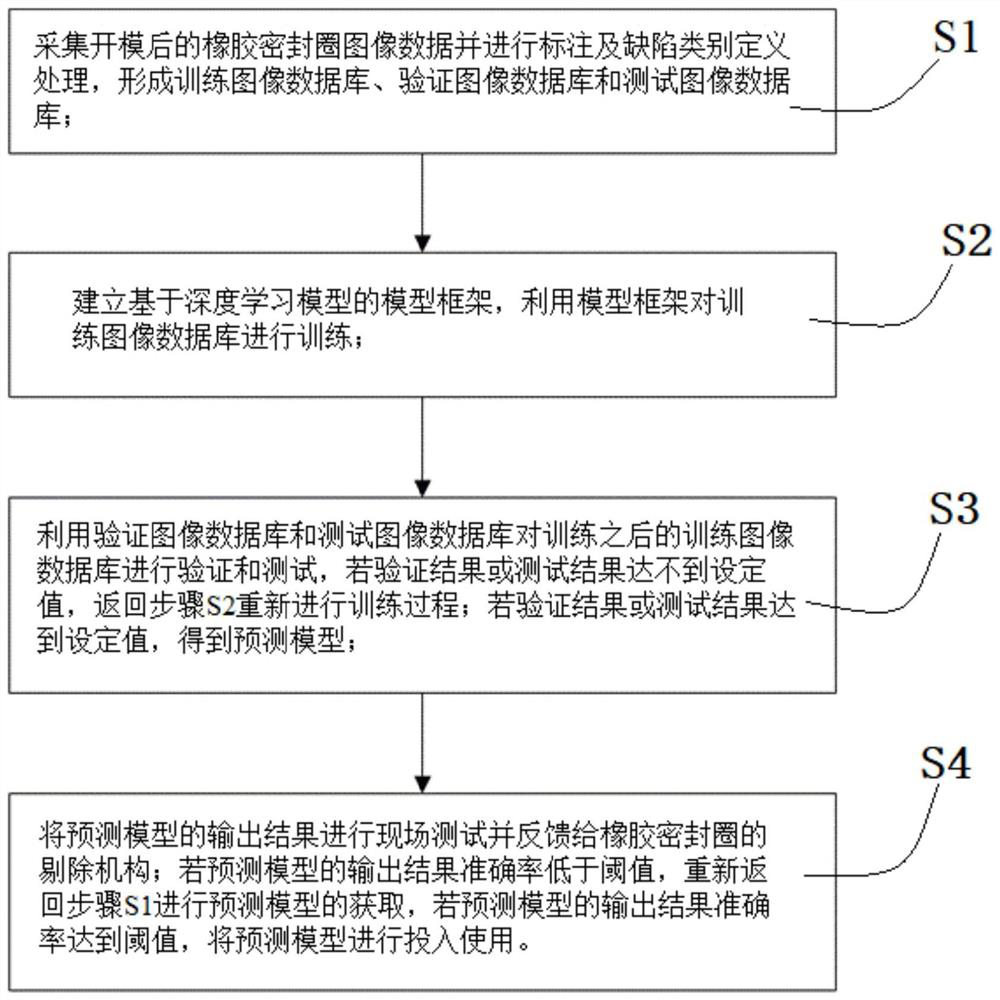

[0024] Such as Figure 1 to Figure 2 As shown, a deep learning-based rubber sealing ring defect detection method includes the following steps:

[0025] S1. Collect the image data of the rubber sealing ring after mold opening and perform labeling and defect category definition processing to form a training image database, a verification image database and a test image database.

[0026] Wherein, the specific implementation manner of the above-mentioned step S1 is: use the industrial camera to collect the image data of the rubber sealing ring after mold opening, use the labelImg software to label and process the image data of the rubber sealing ring collected to obtain the xml file, and to The image data xml files after labeling and defect category definition processing are classified to form a training image database, a verification image database and a test image database, and generate images corresponding to the training image database, verification image database and test im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com