Water control well completion pipe string with tripping-in variable-density screen pipe and continuous packer

A well completion pipe string and variable density technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the control of fluid inertial force and viscous resistance, lack of improvement or explanation of water control mechanism, and have not yet been applied Gas field water control and other issues, to prevent formation water coning, prolong the time of water breakthrough, the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

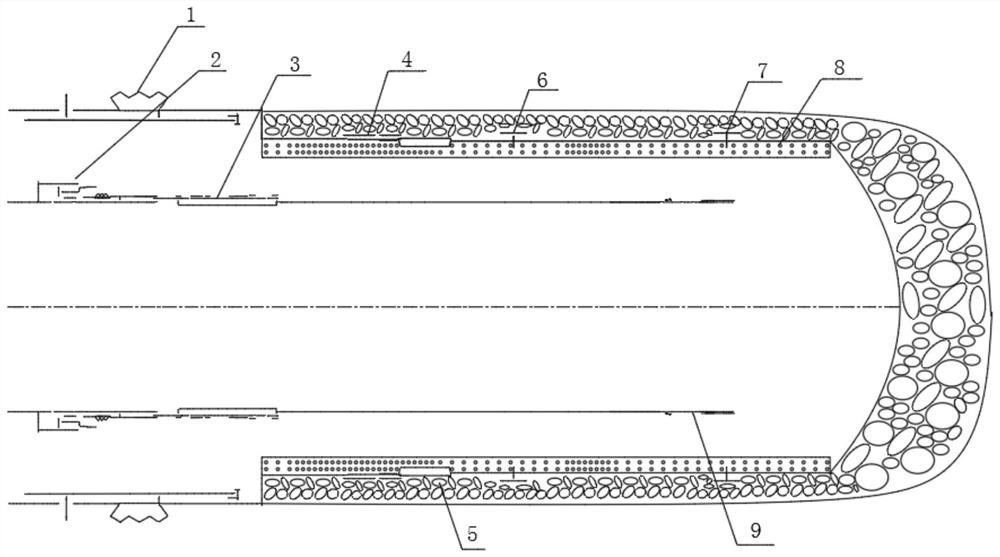

[0015] Example: see figure 1 , the present invention provides a technical solution: a water control completion pipe string run into a variable density screen and a continuous packer, including a variable density screen 8, a quick joint 7, a positioning extension barrel 6, and a packing sleeve 4 , top packer 1, mechanical positioner 9, hydrophobic gravel 5, hand removal tool 3, setting tool 2.

[0016] Among them, the top packer 1 and the setting tool 2 are set at the top of the wellhead to support the lower conduit and all technical casings, and can safely seal off the formation under extreme conditions, ensuring that the completion can be completed under relatively safe conditions. For well operation, the release tool 3 is set in the inner cavity of the pipe string and connected by the setting tool 2 to prevent the pipe string from falling off and make it impossible to continue the follow-up work. There are hydrophobic gravel 5, the inner cavity of the pipe string is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com