Ultrasonic motor with microstructures on surface

An ultrasonic motor and surface micro-modeling technology, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as poor wear resistance of friction pairs, and avoid wear and tear. , The effect of stable friction torque and friction performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

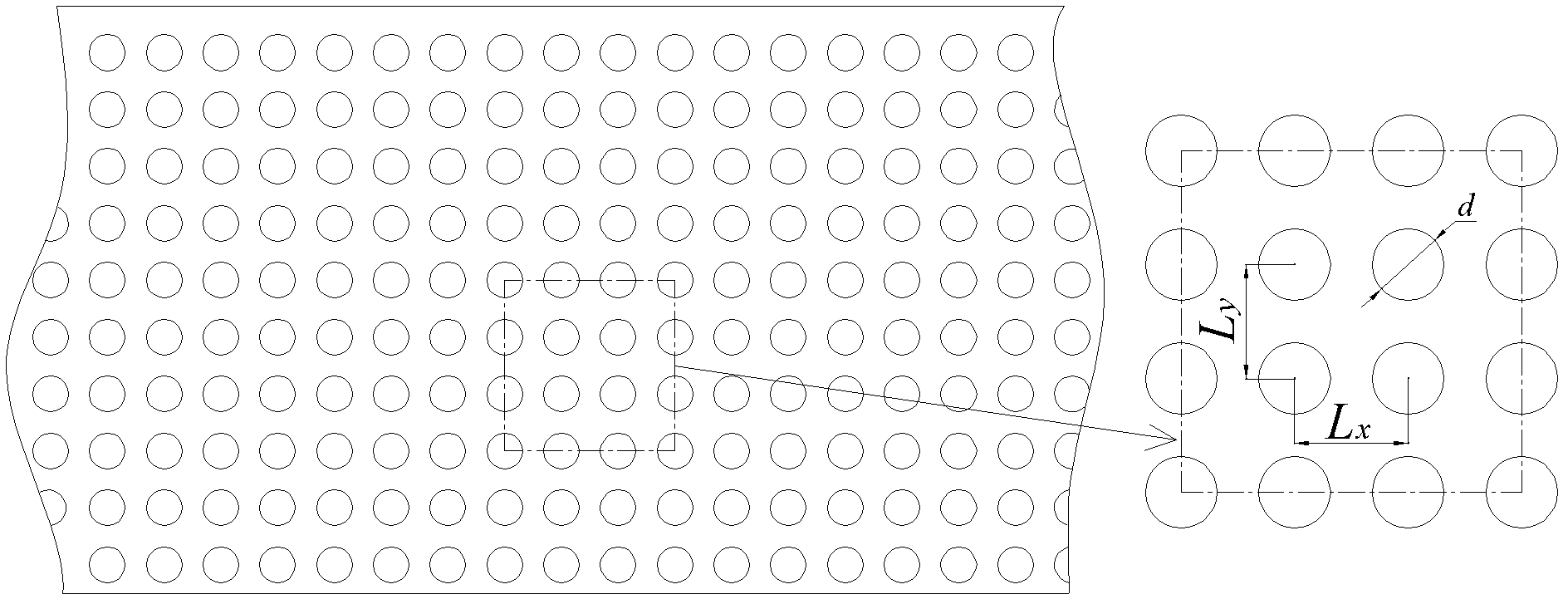

[0026] Specific implementation mode one: the following combination figure 1 and figure 2 This embodiment is described. The ultrasonic motor with surface micro-modeling described in this embodiment includes a stator and a mover. The contact surface area of the stator in contact with the mover is evenly arranged with micro-models. The micro-models are Asperities, microdimples or microgrooves.

specific Embodiment approach 2

[0027] Specific implementation mode two: the following combination figure 1 and figure 2 Describe this embodiment, the ultrasonic motor with surface micro-modeling described in this embodiment includes a stator and a mover, and micro-models are evenly arranged on the contact surface area of the mover in contact with the stator, and the micro-models are Asperities, microdimples or microgrooves.

[0028] The microscopic shapes described in the first or second embodiment have certain arrangement rules, and can be selectively and optimally shaped on the surface of the stator or the rotor.

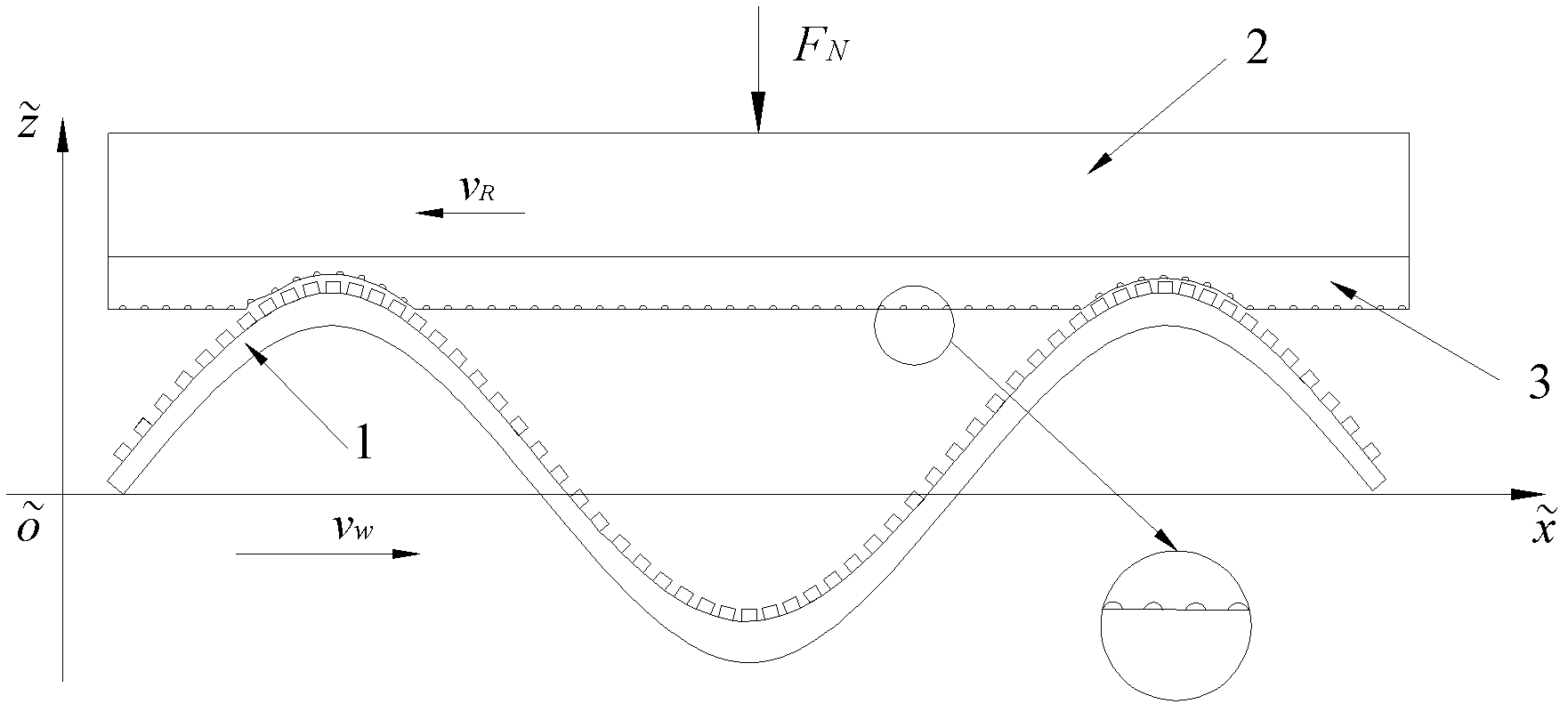

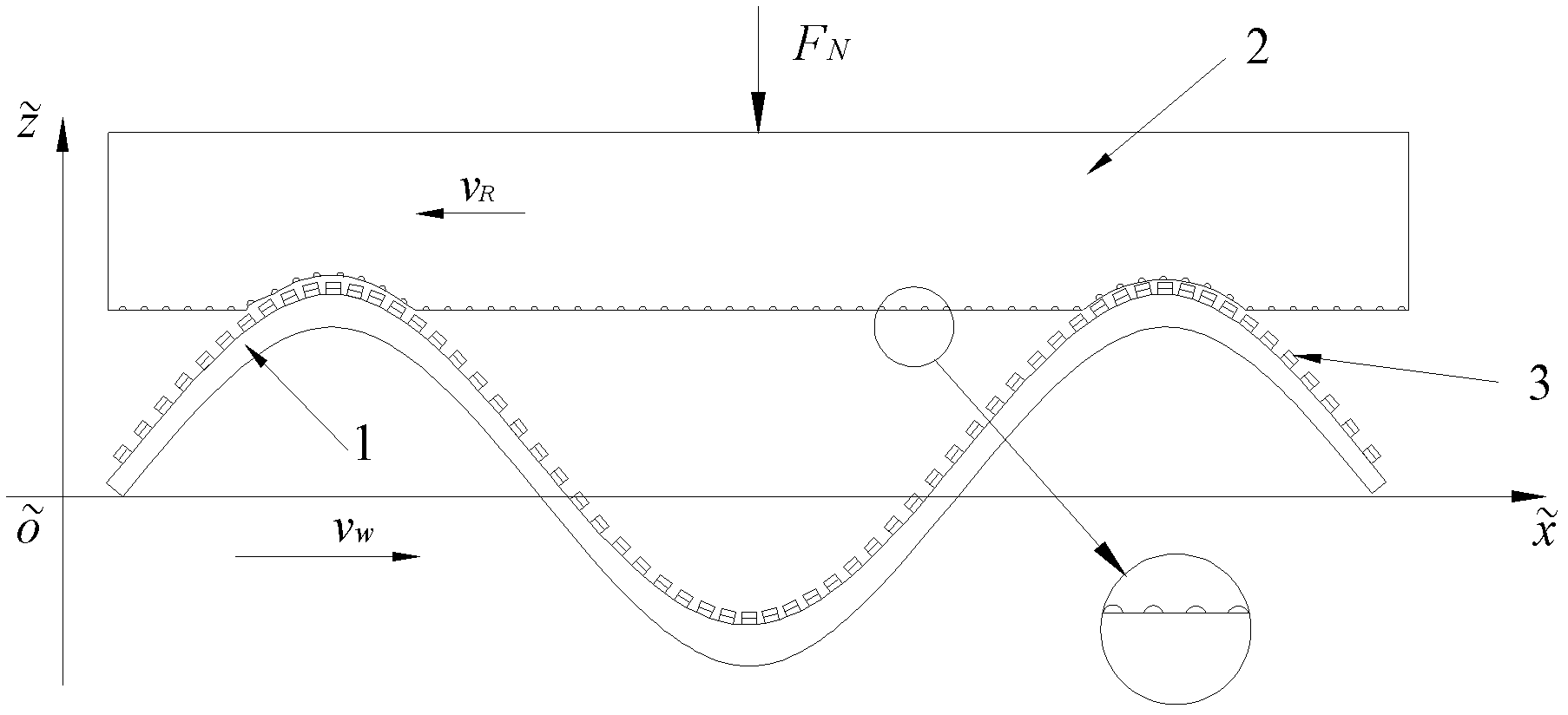

[0029] Such as figure 1 As shown in the figure, the stator produces stretching deformation through the elliptical movement of its surface particles, and then acts on the rotor with the friction layer in the form of friction contact, thereby driving the rotor to rotate.

[0030] figure 2 The driving curve shown is a driving schematic diagram in which the stator does not contain a frictio...

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment is a further description of Embodiment 1 or 2, and the ultrasonic motor is a rotary motor or a linear motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com