Matte silver foil and production method thereof

A manufacturing method and technology of silver cardboard, which is applied in the manufacture of frosted silver cardboard and in the field of frosted silver cardboard, can solve problems such as paper deformation, failure to print with color groups, paper breakage, etc., and achieve the goal of environmental protection and process saving in the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

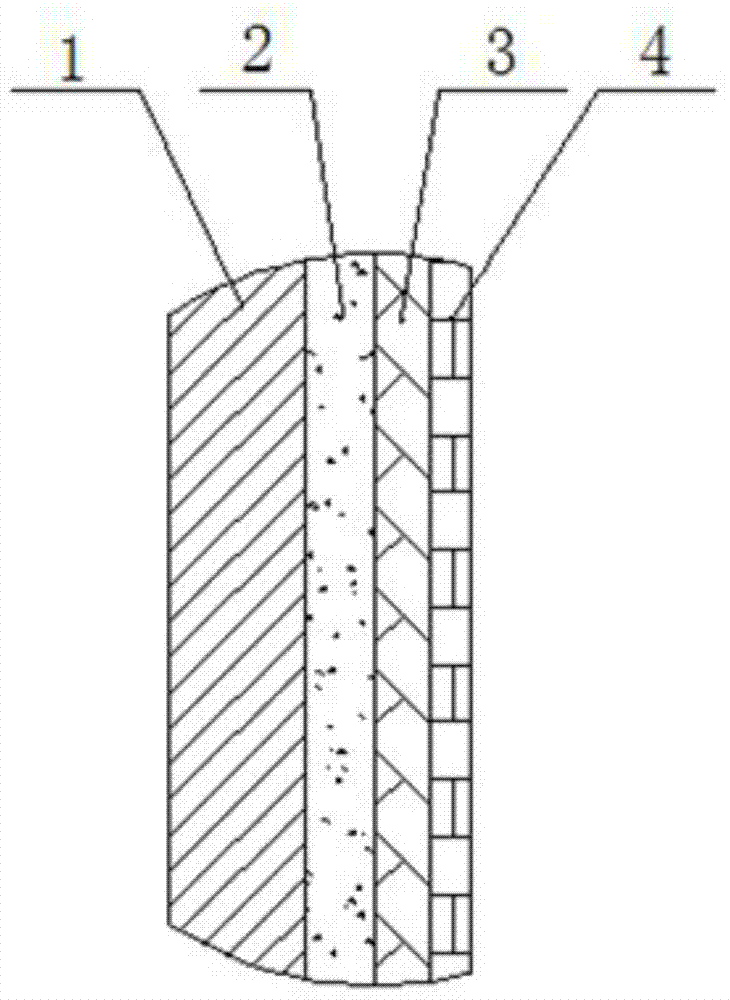

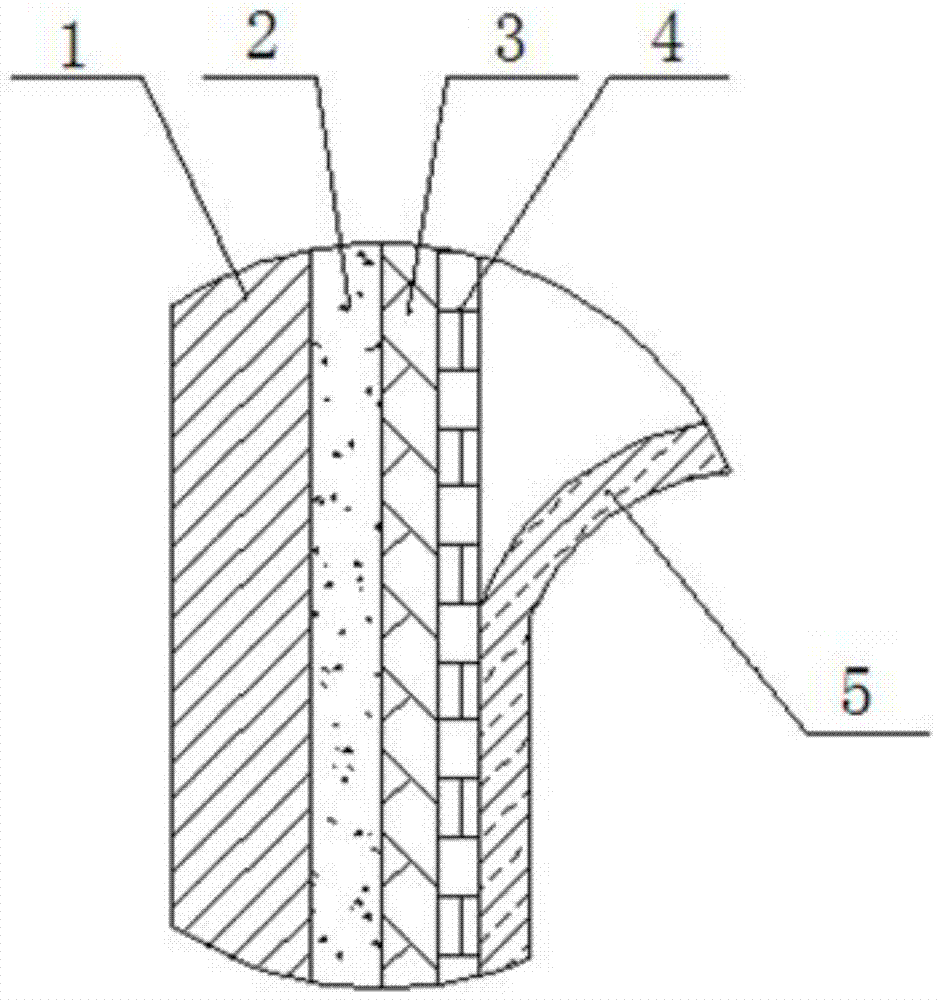

[0026] figure 1 It is a structural representation of frosted silver cardboard of the present invention, as figure 1 As shown, the frosted silver cardboard comprises a base paper layer 1, an adhesive layer 2 coated on one side surface of the base paper layer 1, an frosted silver layer 3 coated on the adhesive layer 2, and coated on The surface coating on the frosted silver layer 3, in this embodiment, the surface coating is a transparent acrylic paint layer 4.

[0027] The base paper layer 1 can be coated paper, white cardboard with white core, white cardboard with yellow core or white cardboard with gray background, and the weight ranges from 80 to 350g / m 2 , preferably 200-230g / m 2 White core white cardboard. Base paper layer 1 in the present embodiment adopts 225g / m 2 white cardboard with white core.

[0028] Adhesive layer 2 adopts polymerized styrene-butadiene emulsion.

[0029] The frosted silver layer 3 is formed by coating with frosted silver paste. The frosted si...

Embodiment 2

[0037] In the second embodiment, coated paper is used as the base paper layer.

[0038] The manufacturing method of the frosted silver cardboard of the present embodiment comprises the following steps:

[0039] Step 1: First use a BOPET film with a thickness of 14 μm, and coat a transparent acrylic paint on a coating machine at a speed of 100 m / min, with a dry weight of 1.2 g / m 2 . The acrylic paint is dried and cured at 120° C. to obtain the acrylic paint layer 4 , and the acrylic paint layer 4 and the BOPET film are collectively called a coating film; forming a coating film.

[0040] Step 2, on the coating surface of the coating film obtained in step 1, coat the frosted silver paste at a speed of 50m / min, and the dry coating amount of the frosted silver paste is 12g / m 2 , and then dried and solidified at 90° C. to form a frosted silver layer 3 . The three-layer structure formed in step 2 is called a frosted silver transfer film. The frosted silver paste is made of non-lea...

Embodiment 3

[0045] In Example 3, white cardboard with a yellow core is used as the base paper layer.

[0046] Step 1: first use a BOPET film with a thickness of 16 μm, and coat a transparent acrylic paint on a coating machine at a speed of 120m / min, with a dry weight of 1.4g / m 2. The acrylic paint layer 4 is obtained after the acrylic paint is dried and cured at 150° C., and the acrylic paint layer 4 and the BOPET film are collectively referred to as a coating film.

[0047] Step 2, on the coated surface of the coating film obtained in step 1, coat the frosted silver paste at a speed of 60m / min, and the dry coating amount of the frosted silver paste is 15g / m 2 , and then dried and solidified at 120° C. to form a frosted silver layer 3 . The three-layer structure formed in step 2 is called a frosted silver transfer film. The frosted silver paste is composed of non-leafing aluminum powder with a particle size of 50 μm and a binder for ink; the weight of the aluminum powder accounts for 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com