Anti-bacterial viscose fiber and preparation method thereof

A technology of viscose fiber and viscose, which is applied in the field of composite production of antibacterial fiber with nano-silver glue solution and cellulose pulp, which can solve the problems of environmental protection, eutrophication of water body, damage, etc., and achieve easy identification and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

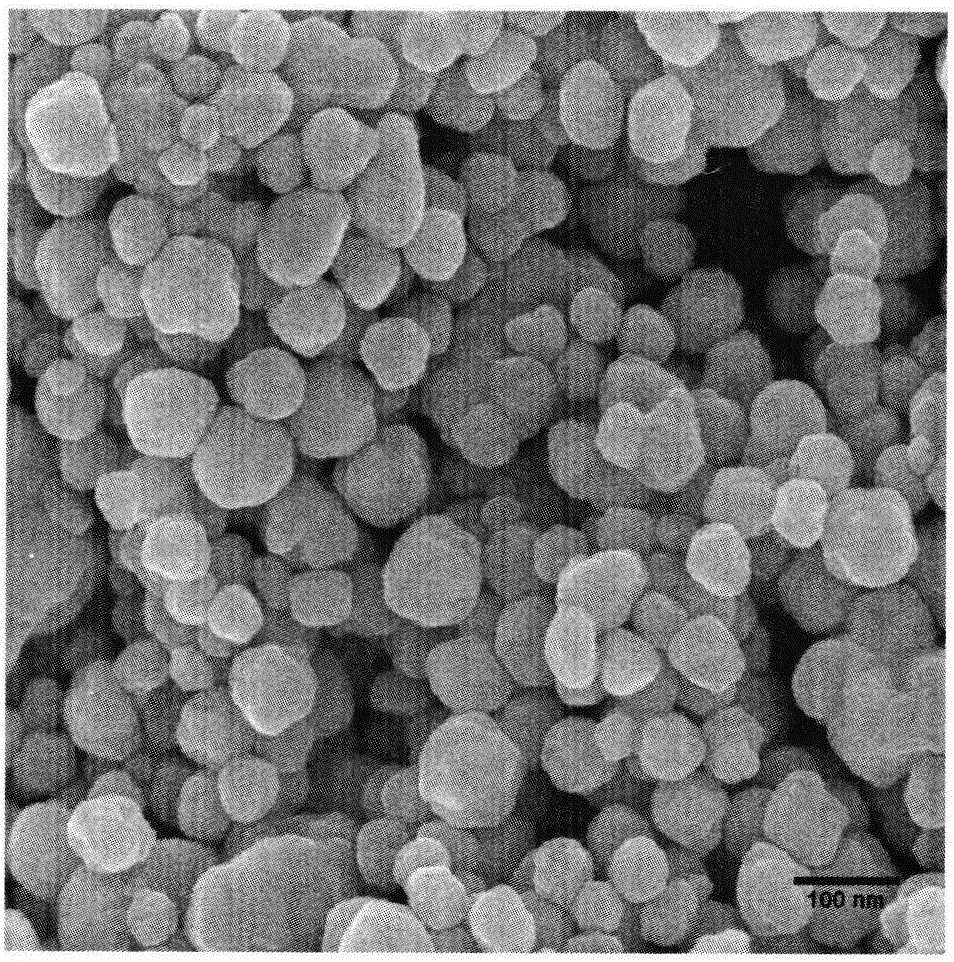

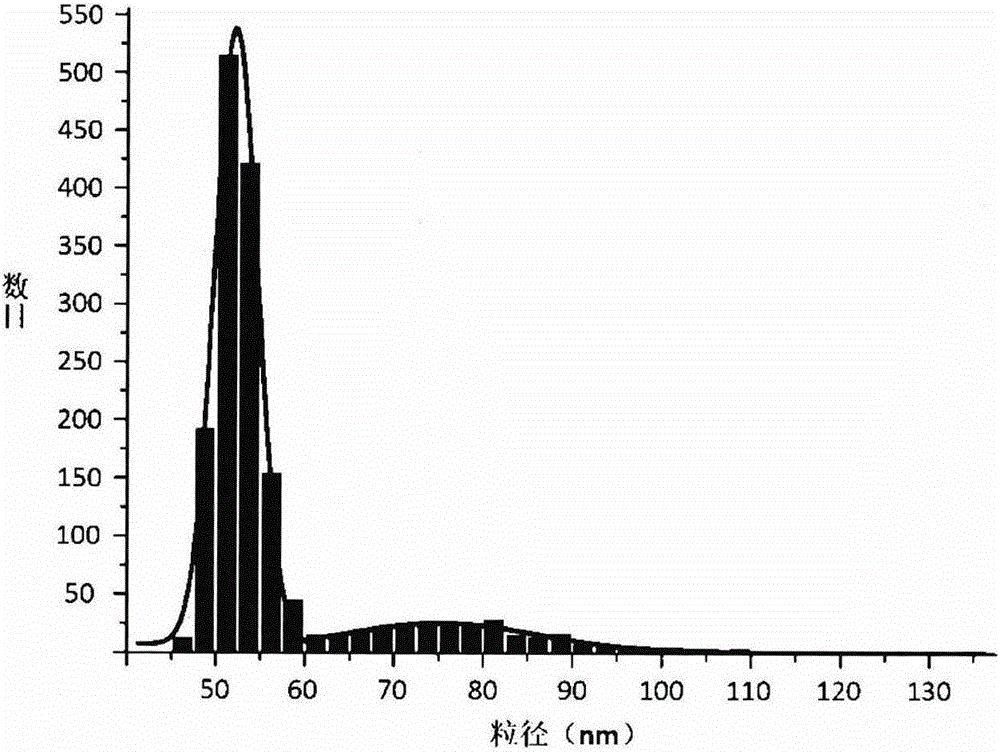

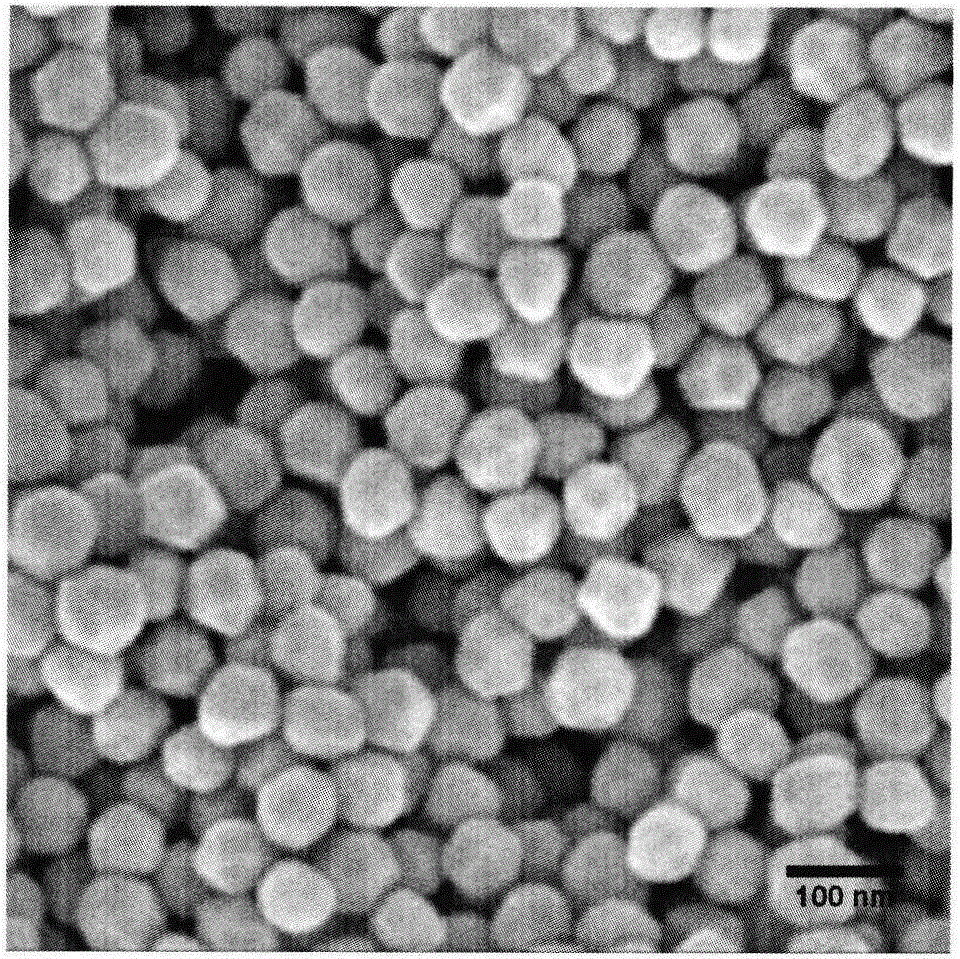

[0031] The nano-silver colloid solution is obtained by mixing the 1% mass percentage concentration of Mopancao extract solution and the 1% mass percentage concentration of silver nitrate solution according to the volume ratio of 1:10, and incubating at room temperature for 9 hours.

[0032] In the process of making glue

[0033] (1) Impregnation: The immersion temperature is 45°C, the concentration of lye is 200g / L, and the immersion time is 45min.

[0034] (2) Pressing: the content of methyl fiber is 26%, and the content of sodium hydroxide is 13%.

[0035] (3) Aging: The temperature is 55°C, and the aging time is 60 minutes.

[0036] (4) Yellowing: the amount of carbon disulfide is 32%, the temperature is 32°C, and the time is 100min.

[0037] (5) Addition amount of nano-silver particles: 6‰. (Based on the amount of nail fiber).

[0038] During the preparation of antibacterial viscose fiber

[0039] (1) spinning: acid bath composition: sulfuric acid 100g / L sodium sulfat...

Embodiment 2

[0054] The nano-silver colloid solution is obtained by mixing the 1% mass percentage concentration of Mopancao extract solution and the 1% mass percentage concentration of silver nitrate solution according to the volume ratio of 1:18, and then incubating at room temperature for 12 hours.

[0055] In the process of making glue

[0056] (1) Impregnation: The immersion temperature is 60°C, the lye concentration is 220g / L, and the immersion time is 60min.

[0057] (2) Pressing: the content of methyl fiber is 30%, and the content of sodium hydroxide is 16%.

[0058] (3) Aging: The temperature is 60°C, and the aging time is 100 minutes.

[0059] (4) Yellowing: the amount of carbon disulfide is 42%, the temperature is 40°C, and the time is 110min.

[0060] (5) The amount of nano-silver particles added: 8‰. (Based on the amount of nail fiber).

[0061] During the preparation of antibacterial viscose fiber

[0062] (1) spinning: acid bath composition: sulfuric acid 120g / L sodium s...

Embodiment 3

[0077] The nano-silver colloid solution is obtained by mixing the 1% mass percentage concentration of Mopancao extract solution and the 1% mass percentage concentration of silver nitrate solution according to the volume ratio of 1:5, and incubating at room temperature for 6 hours.

[0078] In the process of making glue

[0079] (1) Impregnation: The immersion temperature is 40°C, the concentration of lye is 200g / L, and the immersion time is 30min.

[0080] (2) Pressing: the content of methyl fiber is 24%, and the content of sodium hydroxide is 12%.

[0081] (3) Aging: The temperature is 20°C, and the aging time is 40 minutes.

[0082] (4) Yellowing: the amount of carbon disulfide is 25%, the temperature is 20°C, and the time is 70min

[0083] (5) Addition amount of nano-silver particles: 3‰. (Based on the amount of nail fiber).

[0084] During the preparation of antibacterial viscose fiber

[0085] (1) spinning: acid bath composition: sulfuric acid 90g / L sodium sulfate 28...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| dry strength coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com