Method for extracting lithium carbonate from scrapped lithium iron phosphate battery positive electrode powder

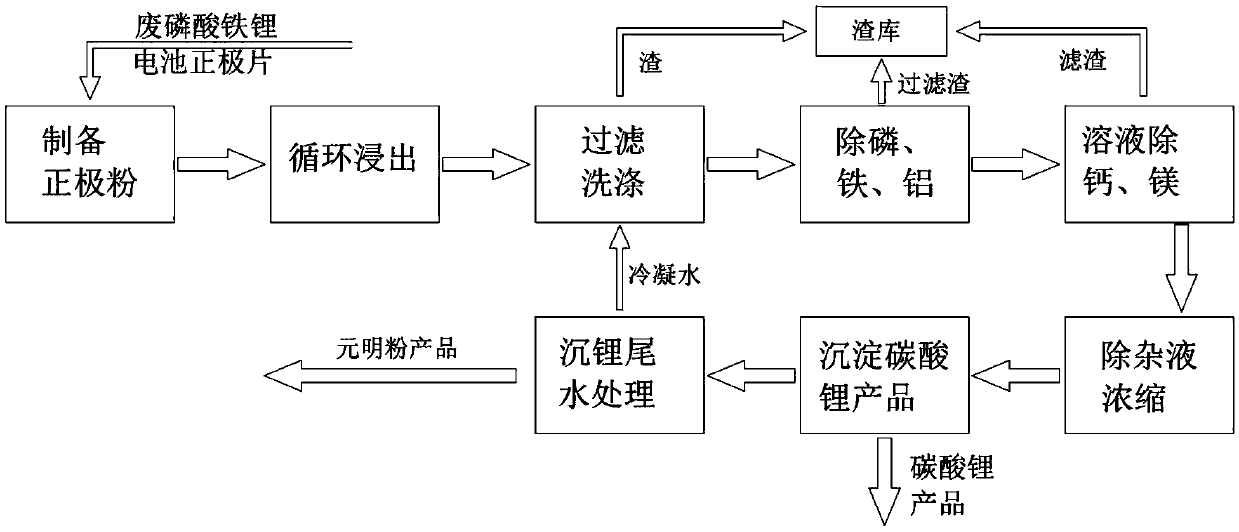

A technology of lithium iron phosphate battery and waste lithium iron phosphate, which is applied in the direction of lithium carbonate;/acid carbonate, battery recycling, sulfate/bisulfate preparation, etc. Human body impact and other issues, to achieve the effect of good product quality, short process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

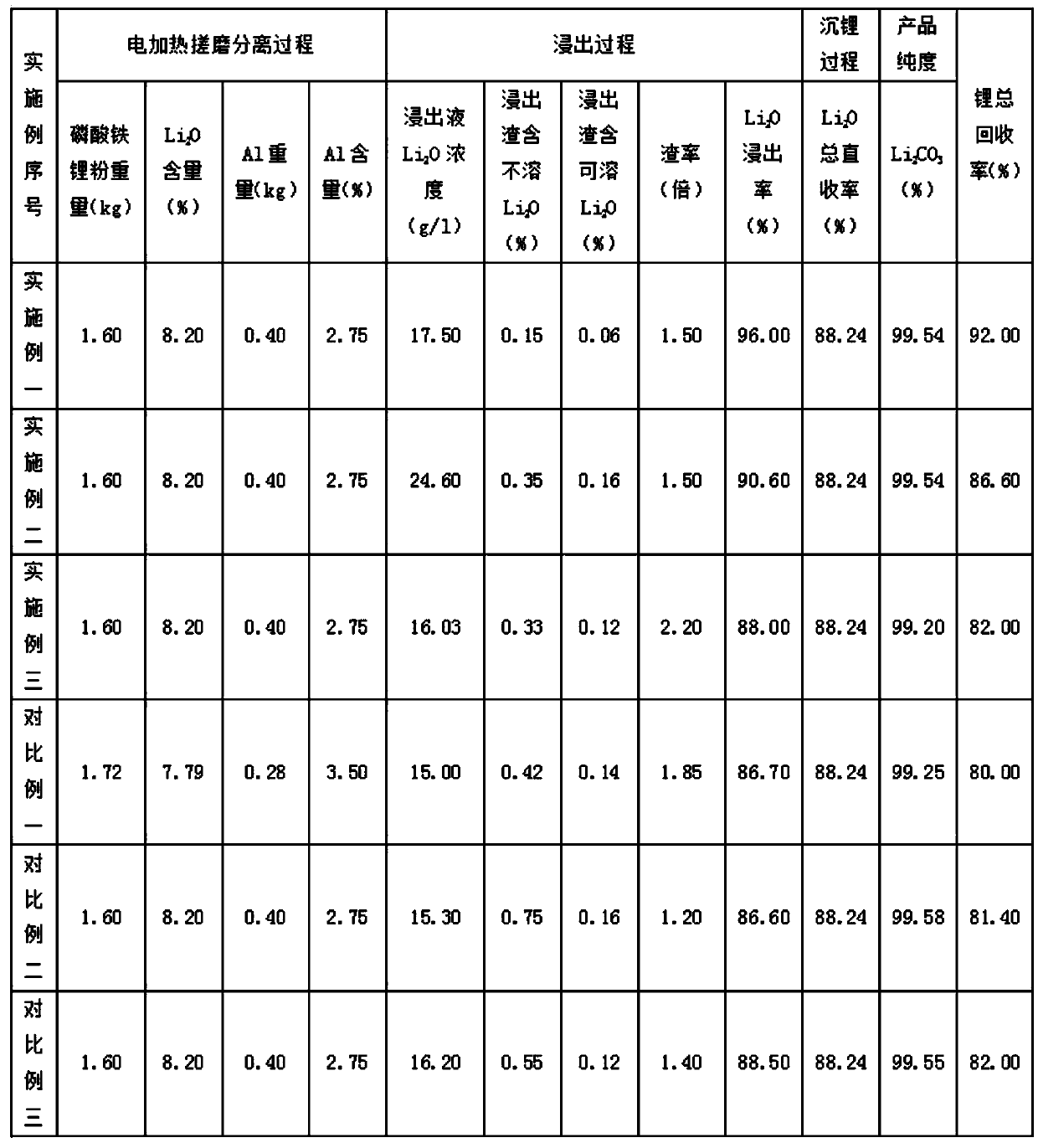

[0032] Step 1: Put 2kg of scrap lithium iron phosphate positive electrode into an electric heating grinding machine to separate positive electrode powder and aluminum. The electric heating time is 1.5 minutes, the heating temperature is 220°C, and the mesh number of lithium iron phosphate positive electrode powder is -400, accounting for 87%. , lithium iron phosphate positive electrode powder: aluminum particles = 80: 20, the weight of lithium iron phosphate positive electrode powder is 1.6 kg, and the aluminum particle is 0.4 kg. The composition is shown in Table 1.

[0033] Step 2: Obtain 1.6kg of lithium iron phosphate cathode powder, add water to the reaction tank at a solid-to-liquid ratio of 1:4.5 to make a slurry, then slowly add concentrated Sulfuric acid (pay attention to the sink, the time of adding acid should be controlled above 1h) to react without heating, the reaction time is 4h, then add limestone powder (CnCO3≥90%), adjust the pH value of the solution to 4, th...

Embodiment 2

[0039] Compared with Example 1, in step 2, 1.6 kg of lithium iron phosphate positive electrode powder separated from 2 kg of scrap lithium iron phosphate positive electrode sheet by electric heating rubbing machine, the difference is that water is added to the reaction at a solid-to-liquid ratio of 1:3 Slurry mixing in the tank, the process before and after is the same as in Example 1, the results are shown in figure 2 .

Embodiment 3

[0041] Compared with Example 1, in step 2, 1.6 kg of lithium iron phosphate positive electrode powder separated from 2 kg of scrap lithium iron phosphate positive electrode sheet by electric heating rubbing machine, the difference is that the ratio of positive electrode powder: acid = 1: 0.65 is added slowly Concentrated sulfuric acid, the leaching slag dry agent slag rate is 2.2 times that of positive electrode powder, the process before and after is the same as embodiment one, the results are shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com