Hydrogenation catalyst, preparation method and application thereof

A hydrogenation catalyst and hydrogenation reaction technology, which are applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high catalytic cost, low hydrogenation catalyst activity, problems such as low selectivity, to achieve the effects of simple preparation conditions, low cost, and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

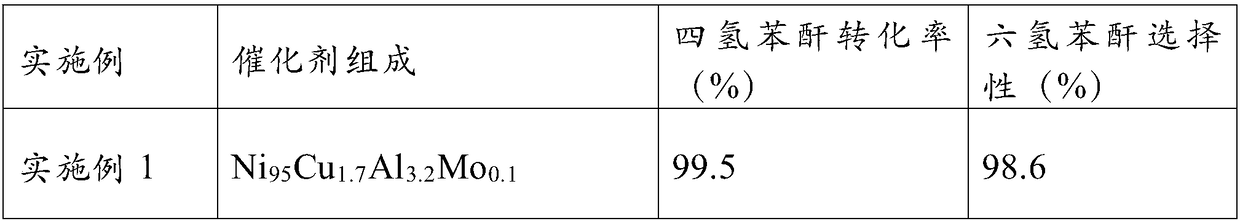

Embodiment 1

[0024] The present embodiment provides that the particle size is less than 100 meshes and consists of Ni 55 Cu 2 al 42.9 Mo 0.1 The process of preparing hydrogenation catalyst by lye activation treatment of metal alloy particles.

[0025] The preparation method of the hydrogenation catalyst in this embodiment specifically includes: adding 500 g of NaOH solution with a concentration of 25 wt % into a 1 L three-necked flask, the conductivity of the water used in the configuration of the NaOH solution is 10 μs / cm, and accurately weighing the particles The diameter is less than 100 mesh, and the composition is Ni 55 Cu 2 al 42.9 Mo 0.1 Add 100 g of metal alloy particles from the above-mentioned NaOH solution, control the reaction temperature to 150° C., stir at 400 r / min, and react for 2 hours to obtain activated metal alloy particles. Wash the activated metal alloy particles with deionized water at 30° C. Alloy particles, stop washing when the pH of the washing solution is...

Embodiment 2

[0027] The present embodiment provides that the particle size is less than 100 meshes and consists of Ni 43 Cu 3 al 53.5 Mo 0.5 The process of preparing hydrogenation catalyst by alkali solution activation treatment of metal alloy powder.

[0028] The hydrogenation catalyst was prepared according to the method described in Example 1, except that the concentration of NaOH solution was 35wt%, the conductivity of water was 200 μs / cm, the reaction time was 0.5h, and the reaction temperature was 60°C. ℃ deionized water to wash until the pH of the washing solution is 8, stop washing, and obtain a composition of Ni 90.2 Cu 4.3Al 4.6 Mo 0.9 hydrogenation catalyst.

Embodiment 3

[0030] The present embodiment provides that the particle size is less than 100 meshes and consists of Ni 40 Cu 4 Al 55 Mo 1 The process of preparing hydrogenation catalyst by alkali solution activation treatment of metal alloy powder.

[0031] The hydrogenation catalyst was prepared according to the method described in Example 1, except that the reaction temperature was 110°C, and the obtained composition was Ni 85.8 Cu 10 Al 3.0 Mo 1.2 hydrogenation catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com