Manufacturing method for honeycomb structure made of composite material and equipment used for manufacturing honeycomb structure made of composite material

A technology of honeycomb structure and composite material, which is applied in the field of manufacturing of composite material honeycomb structure and equipment for manufacturing composite material honeycomb structure, can solve problems such as poor environmental protection, and achieve the effect of environmental protection in production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1, the production of prepreg:

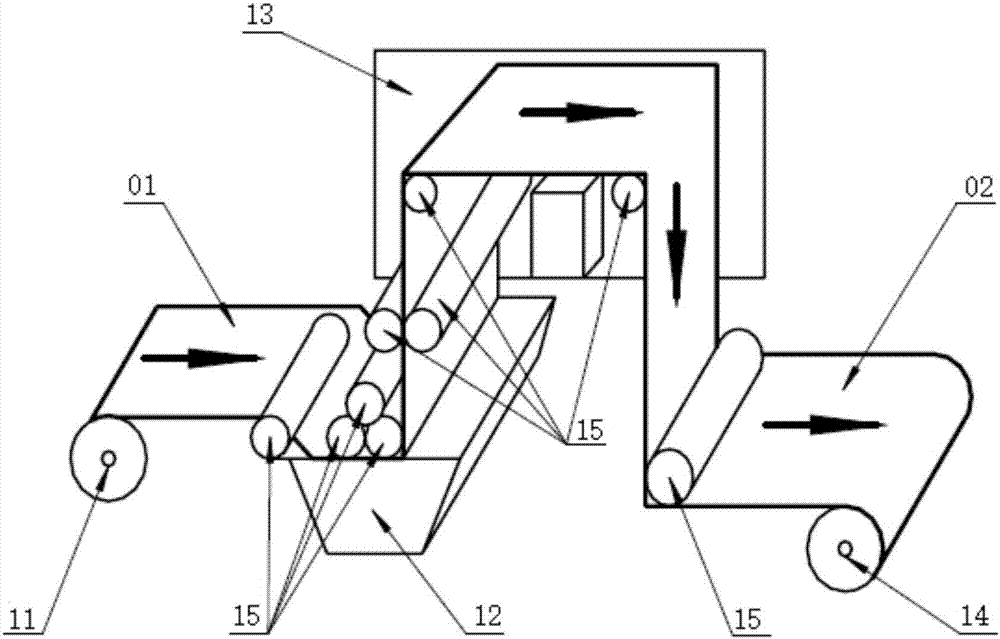

[0039] Such as figure 1 As shown, the carbon fiber cloth roll 01 is placed on the unwinding roller 11, and the unwinding roller 11 is rotatably arranged. Unwinding roller 11 rotates and carbon fiber cloth 02 can be released. The end of the carbon fiber cloth 02 is wound on the take-up roller 14 . The winding roller 14 is rotatably provided. The winding roll 14 rotates to wind the carbon fiber cloth 02 into rolls. A resin tank 12 , a resin curing device 13 , and a plurality of rollers 15 are arranged between the unwinding roller 11 and the winding roller 14 . The resin tank 12 is used to hold the resin; the resin curing device 13 is used to cure the resin impregnated with the fiber cloth; the multiple rollers 15 are used to support the fiber cloth 02 . Pulled by the winding roller 14, the fiber cloth 02 enters the resin tank 12 to be impregnated with resin in sequence, and then passes through the resin curing device 13 to cure th...

Embodiment 2

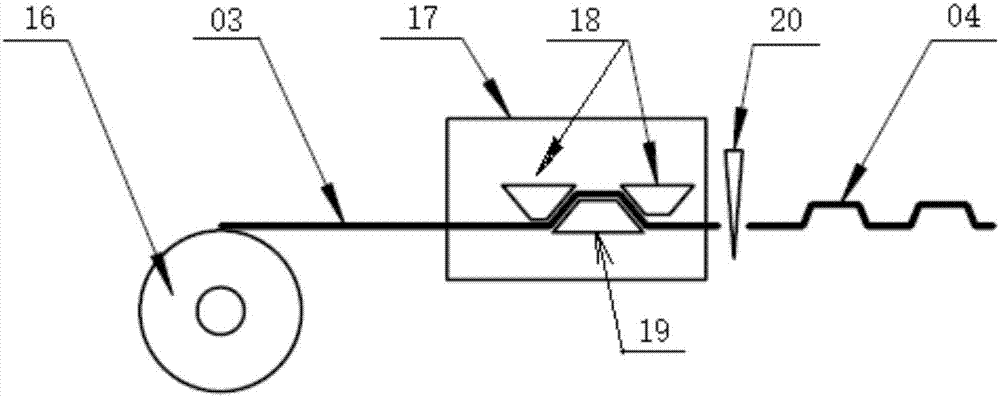

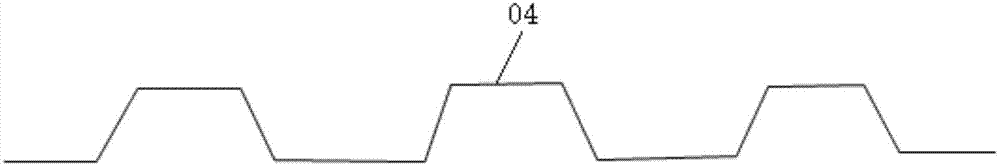

[0054] The difference between this embodiment and Embodiment 1 is that after the fiber cloth is impregnated with resin, before the resin is cured or during the resin curing process, the prepreg is punched by molding equipment to make it into the required shape, and then processed by the resin curing equipment. Finally, the corrugated sheet of the desired shape is formed.

[0055] Such as Figure 7 As shown, the fiber cloth 05 is released from the unwinding frame 21 with the fiber cloth 05, and the heated thermosetting resin (without solvent) is placed in the heating resin tank 22, and the released glass fiber cloth 05 is put into the heating resin The thermosetting resin is soaked in the tank, and then the fiber cloth soaked with the thermosetting resin is directly sent into the heating and softening oven 23, and the forming mold 24 is molded in the heating and softening oven 23 to form a corrugated sheet 06 of a specific shape. A cutting device 25 is provided at the exit of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com