A method for producing ternary precursor and high-purity lithium carbonate from a waste ternary lithium battery

A ternary lithium battery and high-purity lithium carbonate technology, applied in lithium carbonate;/acid carbonate, battery electrodes, secondary batteries, etc., can solve the problem of high value-added recovery of manganese and lithium, and investment Large, complicated process and other problems, to achieve the effect of environmentally friendly production process, reduced unit investment, and simple impurity removal method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

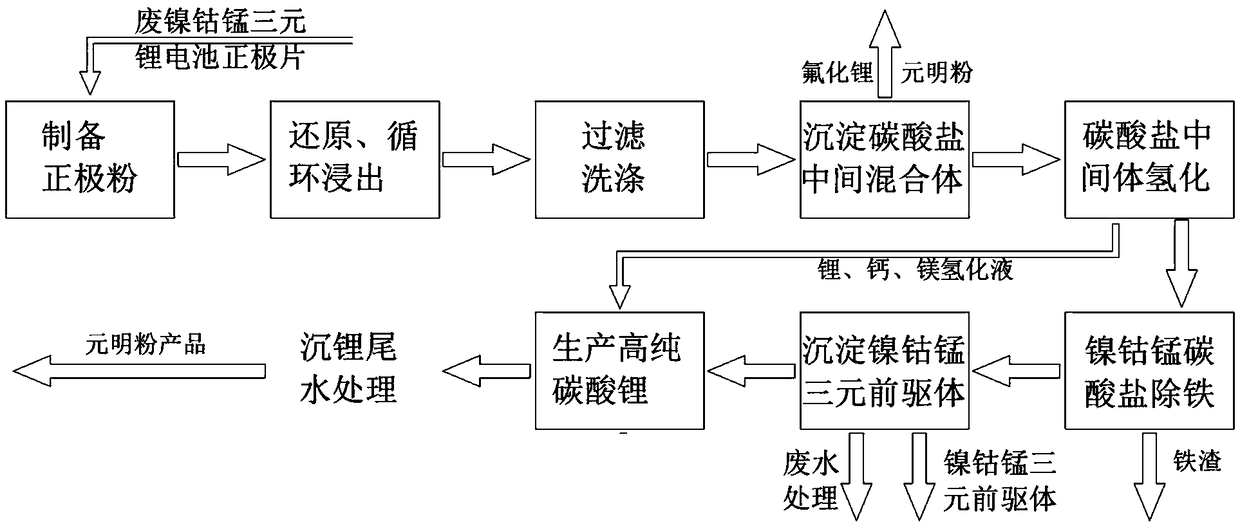

Method used

Image

Examples

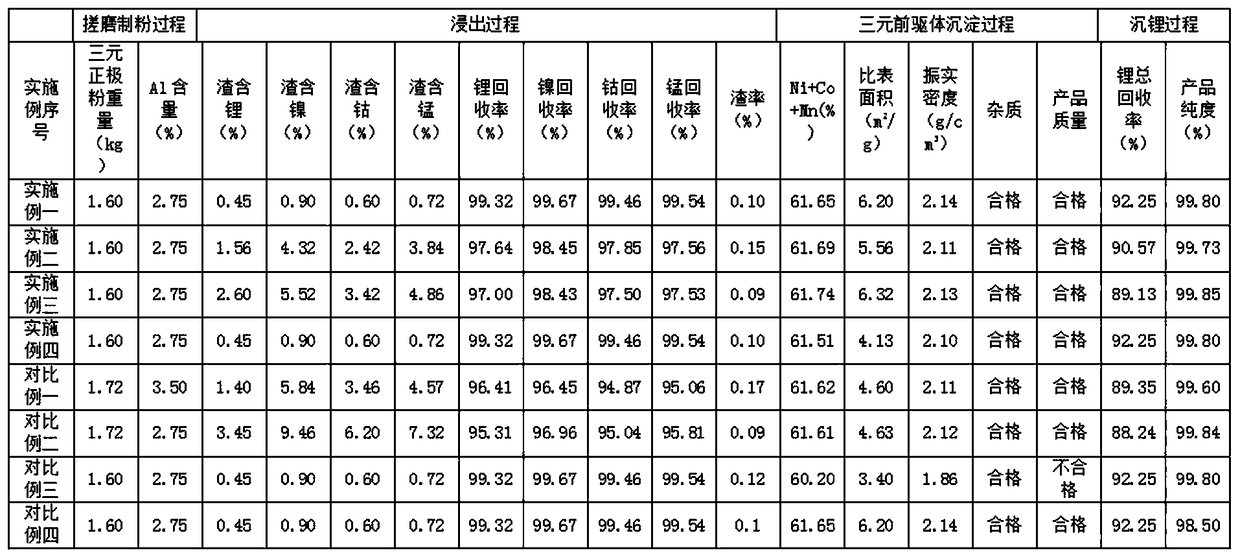

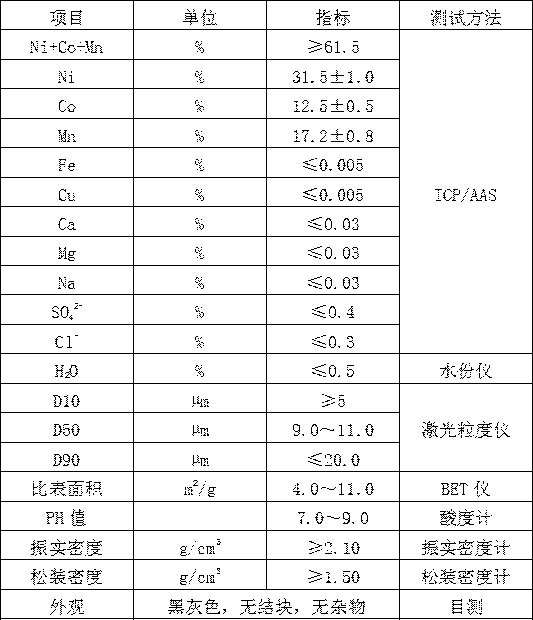

Embodiment 1

[0041] Step 1: Put 2kg of waste nickel-cobalt-manganese ternary lithium battery positive plate (NCM523) into an electric heating grinding machine to separate positive electrode powder and aluminum. The electric heating time is 1.5 minutes, and the heating temperature is 220°C. The mesh number of the lithium battery positive electrode powder is -400 mesh, accounting for 85%. The waste nickel-cobalt-manganese ternary lithium battery positive electrode powder: aluminum = 80: 20, the obtained positive electrode powder is 1.6kg, and the aluminum particle is 0.4kg. The composition is shown in Table 1.

[0042] Step 2: Add 1.6kg of spent nickel-cobalt-manganese ternary lithium battery cathode powder obtained in step 1 into a reaction tank with 8000ml of water to make a slurry, then slowly add 2.4kg of concentrated sulfuric acid, and also add 2kg of 32% hydrogen peroxide and sodium metabisulfite Each accounted for 50% of the mixture (pay attention to the sink, the time of adding acid a...

Embodiment 2

[0050] Compared with Example 1, in step 2, 1.6 kg of the obtained waste nickel-cobalt-manganese ternary lithium battery positive electrode powder was added to 5600 ml of water into a reaction tank to make a slurry. The process before and after is the same as in Example 1, and the results are shown in figure 1 .

Embodiment 3

[0052] Compared with Example 1, in Step 2, slowly add 2.72kg of concentrated sulfuric acid, and also add 1.36kg of 32% hydrogen peroxide and a 50% mixture of sodium metabisulfite. The process before and after is the same as in Example 1. The results are shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com