Device and method for electrically acquiring and purifying carbon dioxide

A carbon dioxide and extraction device technology, applied in chemical instruments and methods, separation methods, electrolysis processes, etc., can solve the problems of complex operation, high energy consumption and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

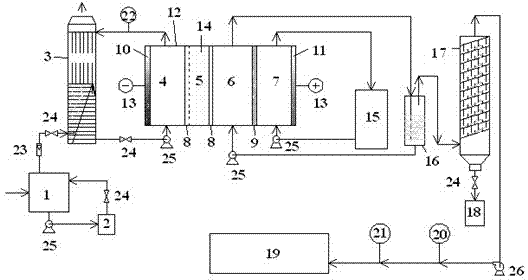

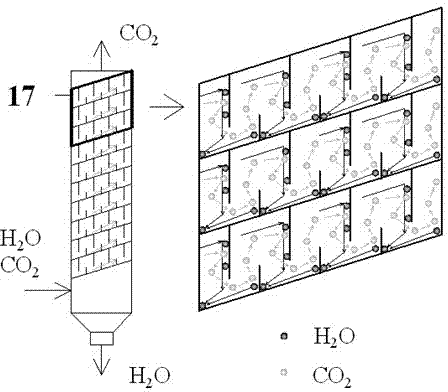

[0025] Such as Figure 1 The carbon dioxide collection and extraction device shown in the figure recovers the carbon dioxide in the exhaust gas of the chimney of the power plant. The concentration of carbon dioxide in the exhaust gas is about 104.1g / m 3 , gas flow rate 100.0m 3 / h, after the gas collection and treatment by the carbon dioxide collection and extraction device, the removal rate of carbon dioxide in the flue gas is 97.4~98.1%, after extraction by the four-compartment EDI device, the conversion rate of acid radicals in the absorbent is 93.1~93.6%, the absorbent Restore alkaline, pH > 13.2. The concentration of carbon dioxide in the extracted carbon dioxide moisture is 67.2~68.3%. The obtained moisture is passed into the gas-liquid separation tower. In the tower, the water vapor and carbon dioxide are subjected to gravity, baffle and cyclone. Due to the large proportion of water vapor, they are blocked Gradually falling to the bottom of the tower, the carbon di...

Embodiment 2

[0027] Such as Figure 1 The carbon dioxide collection and extraction device shown is used to recover carbon dioxide in the coal-fired waste gas of a small boiler plant. The concentration of carbon dioxide in the exhaust gas is about 39.3g / m 3 , gas flow 40m 3 / h, after the carbon dioxide in the waste gas passes through the carbon dioxide absorption tower, the remaining waste gas is discharged, and the carbon dioxide removal rate is about 97.8%. After being extracted by the four-compartment EDI device, the carbonate ions and bicarbonate ions in the absorption liquid enter the concentrated The mobility is 93.2%, and the pH of the absorption liquid entering the EDI device has changed from about 10.0 to above 12.8. The carbon dioxide concentration in the dried out gas is about 99.4%. And the volume of the anion resin filled chamber is 0.45dm 3 , the thickness of the resin layer is 1.8cm, and the effective area of the film is 2.5dm 2 , the voltage is 75V condition.

Embodiment 3

[0029] Such as Figure 1 The shown carbon dioxide collection and extraction device recovers the carbon dioxide in the waste gas discharged from the ammonia synthesis process. The total amount of carbonates treated was 9M, the influent flow rate was maintained at 4L / h, the conversion rate of carbonates was 92.8~93.3%, the purity of the gas after drying was as high as 99.1~99.2%, and the pH of the cathode effluent changed significantly, maintaining Above 12.4. The volume of the anion resin filled chamber is 0.24dm 3 , the thickness of the resin layer is 1.5cm, and the effective area of the film is 1.6dm 2 , the voltage is 75V condition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com