Thermal feeding method and device for calcium carbide furnace

A calcium carbide furnace and hot feeding technology, applied in the direction of carbide, calcium carbide, etc., can solve the problems of waste of energy, leakage of combustible gas, poor safety, etc., and achieve the effect of reducing dust pollution, reducing storage equipment, and increasing airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

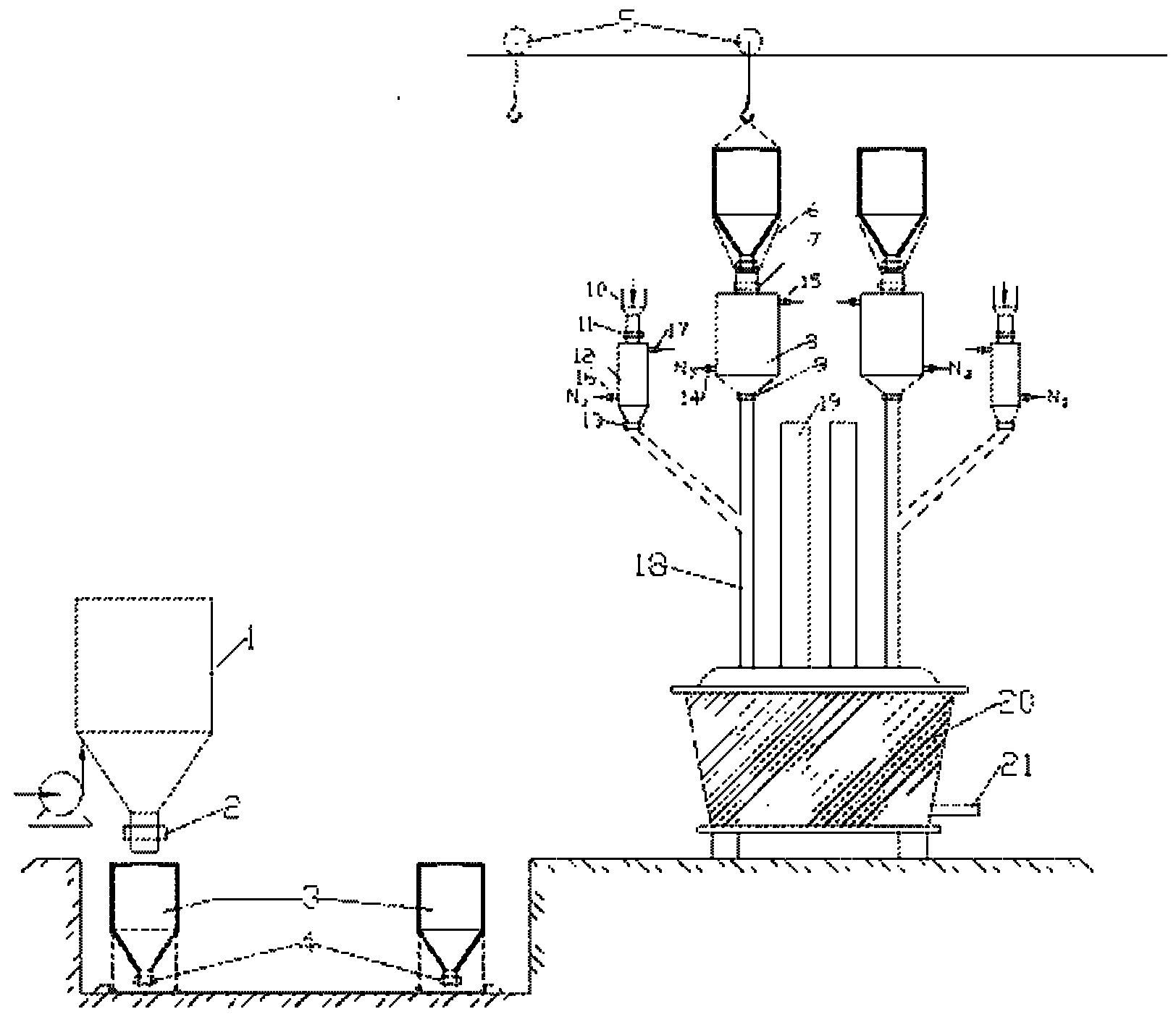

[0013] The method of the present invention includes the following steps:

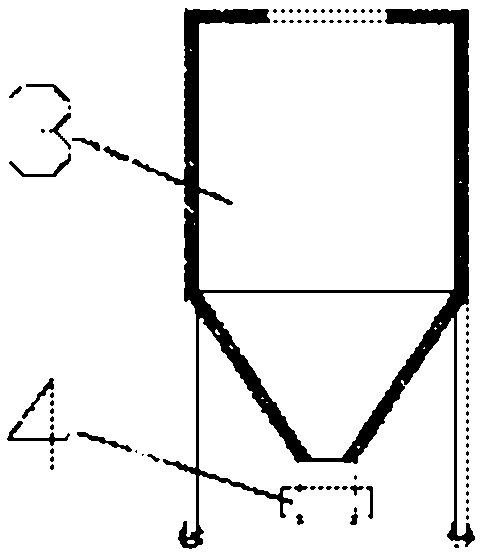

[0014] 1. The high-temperature calcium oxide from the stewing tank is weighed with an automatic scale and poured into the insulated narrow-gauge truck. The traction device of the insulated narrow-gauge truck is transported to the vicinity of the calcium carbide furnace through the track, and is lifted by the monorail crane to the top of the calcium carbide furnace. Feed material to the ring bin through the ring feeder;

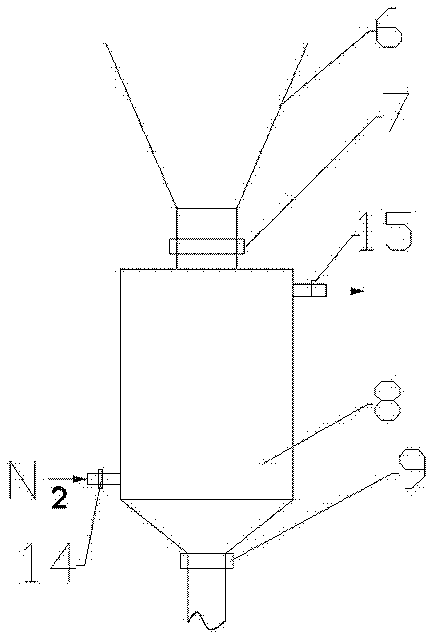

[0015] 2. After calcium oxide is added to the calcium oxide annular silo, the annular silo's inlet is closed, and nitrogen is filled to replace the air. After the replacement is completed, the unloading opening is opened, and the feeding tube is used to feed the calcium carbide furnace;

[0016] 3. After the coke is crushed, sieved, and metered, it is added to the coke ring silo through belt conveyors, elevators and other equipment. The ring silo's inlet is closed and nitrogen is filled to rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com